Olecranon Plate

- No.: Titanium Machining

- Color: Custom

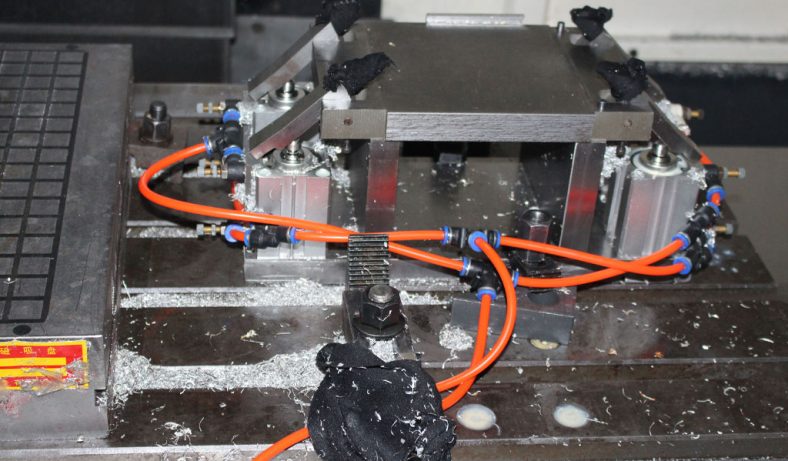

- Machine tool used: JDGR400T

- Workpiece size: 156×17×23mm

- Material: TC4

- Number of tools: 28

- Processing time: 2h20min

- Surface roughness: Ra<0.6um

- Squareness: 100mm

- Product Category: Medical Parts

- Production Process: 5 Axis CNC Machining Medical Parts

- Size: According To Customer’s Drawings

High-Quality Custom 5 Axis CNC Machining Medical Olecranon Plate

The olecranon plate is a specialized orthopedic implant used in the surgical treatment of fractures involving the olecranon, which is the bony prominence of the ulna at the elbow. This plate is designed to stabilize and support the fractured olecranon bone to promote proper healing and restore function.

The olecranon is the prominent bone at the back of the elbow joint, forming the tip of the ulna. It is critical for the extension of the forearm and is connected to the triceps muscle, which facilitates the movement of the arm. Fractures of the olecranon can severely impair elbow function, making effective stabilization essential for recovery.

Olecranon plates are typically used in the management of complex fractures of the olecranon, including:

- Comminuted Fractures: These are fractures where the olecranon is shattered into multiple pieces.

- Displaced Fractures: When the fracture fragments are misaligned and cannot heal properly without surgical intervention.

- Fracture-Dislocations: When the fracture is accompanied by dislocation of the elbow joint.

- These conditions often require surgical intervention to restore proper alignment and function.

Olecranon plates are usually made from biocompatible metals such as stainless steel or titanium. These materials provide the necessary strength and durability while minimizing the risk of rejection by the body. The plates are designed with specific contours and screw holes to match the anatomy of the olecranon and ensure stable fixation.

The plates typically feature:

Pre-contoured Shapes: To match the natural curvature of the ulna and provide a precise fit.

Screw Holes: For the insertion of screws that secure the plate to the bone, allowing for optimal stabilization.

Low Profile Design: To minimize irritation of the surrounding soft tissues and facilitate smoother recovery.

The olecranon plate is a crucial tool in the orthopedic management of olecranon fractures, offering a reliable method for stabilizing and supporting the fractured bone. Through its precise design and the surgical techniques involved, it enables effective treatment of complex fractures, helping patients achieve optimal recovery and return to their daily activities.

The Advantages Of Precision 5 Axis CNC Machining Medical Olecranon Plate

- – Excellent wear and impact resistance

- – Durable and solid, long lifetime

- – Good strength and electrical conductivity

- – Customization based on customer specification

Specifications of Custom 5 Axis CNC Machining Medical Olecranon Plate

| Material | TC4 |

| Tolerance | +/-0.05mm |

| Surface Treatment | Custom |

| Main Process | 5 Axis CNC Machining |

| Quality Control | Strictly Quality control in the whole process, from material to packing, Coordinate-measuring machine |

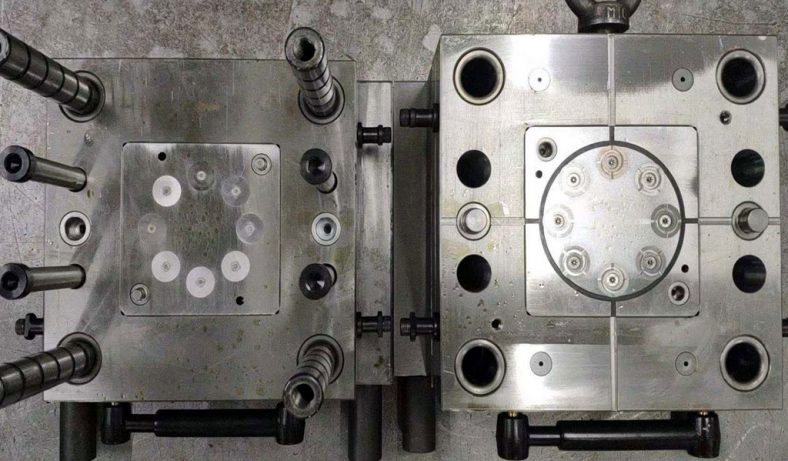

| Usage | Plastic Injection Mould Core |

| Customized Drawings | Auto CAD, JPEG, PDF, STP, IGS, and most other file formats are accepted |

China Top Mold Parts and Mold Making Company

BE-CU.com is a professional manufacturer of precision mould parts. We have the ability to manufacture all kind of precision mold parts, they are commonly used in precision plastic mold, auto mold, medicine mold, and precision automation machine.Our products including: Mold cavity,inserts,core pin,punches, ejector/sleeves pins, sleeves, leader pins, guide sprue bushings, ejector blades etc.We are fully equipped with CNC machining centers, precise surface grinder, numerical control machine, punch formers and precision centerless grinding machines etc.

BE-CU Precision Parts Co.,Ltd. is established in 1995, is a professional manufacturer of precision mould parts. Our factory, located in the mould town--Chang'an. It is a professional company in research, development and manufacturing of precision mould components,we have over 30 years experience in this field,our advanced precision equipment and scientific quality control ensures customers satisfaction.

Our complete and advanced mold making facility provides a fundamental advantage as a complete product solution partner. Whether redesigning an existing mold or embarking on a brand new project, our team is able to deliver the highest quality tooling for molding with some of the shortest lead times in the industry.Our tool room is equipped with the latest resources in mold making technology, including CAM, CNC milling, grinding, EDM, inspection and more. These characteristics, coupled with a highly skilled staff encompass our mold-making department.Whatever you need prototype molds for the short-run production, or mass production molds for millions shots, Be-cu.com can handle them for you smoothly.

-

Precision Grinding Tungsten Steel Mold Parts

-

5 Axis CNC Machining Medical Olecranon Plate

-

Special-Shaped Non-Standard Medical Device Needles

-

High-Speed Steel (HSS) Die Punching Needles

-

Precision Tungsten Copper Alloy Eccentric Insert

-

5 Axis CNC Machining Spiral Bevel Gear Mold

-

Small Precision Injection Molding Inserts

-

OEM Stainless Steel Press Brake Tooling