What Is Injection Mold

Injection mold is a precise, engineered tool used in the injection molding process to produce a variety of parts by injecting molten material into a mold cavity. Mold determines the shape, dimensions, and surface quality of the final product. Injection molds are commonly used in manufacturing plastic parts, but they can also be used for metals and other materials. World War II spurred further advancements in injection mold technology due to the high demand for mass-produced parts. The post-war era saw the development of new thermoplastics and the introduction of automated injection mold machines, which significantly increased production capabilities and precision.

The design and manufacturing of injection molds are critical to the success of the injection molding process and require a high degree of expertise and technology.Plastic mold technology is by far the most popular method to manufacture plastic parts in the world today. This process is used for everything from inexpensive commercial plastic products, like disposable eating utensils, toys to the severe environment, highly stressed technical components, like critical parts for automotive and aerospace industries.

You’ll find extensive use of injection molded plastic parts in the electronics world for things like enclosures for cell phones, computers, televisions, and the like, as well as in the medical world where things like syringe bodies, breathing apparatus and a wide range of other life-saving devices are employed. No other process has come to dominate modern manufacturing as plastic molding, and its use increases every year.

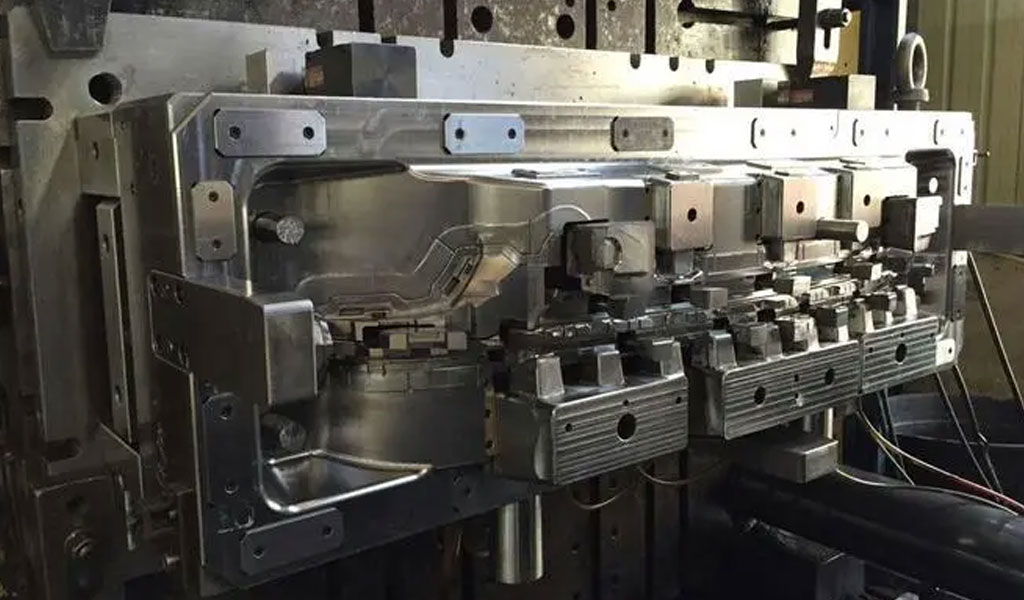

Recently, critical steering components for BMW Motors cars and trucks were changed from stamped and machined steel parts to a plastic molded assembly resulting in a lighter part, at a lower cost, quieter, and more reliable.

Prototype To Plastic Injection Mold & Molding Manufacturing Service

Need injection mold making supplies for mass production parts? Be-Cu prototype is known as the best injection mold and plastic mold parts maker in China. With mold making facilities in house and resources from our partners, we are able to provide plastic molds and mold parts manufacturing for plastic parts for all type of mass project for toys, blocks, and gears and more. We offer low-cost local production molds and high-quality exported molds for all your project needs.

China Plastic Injection Mold/Molding factory

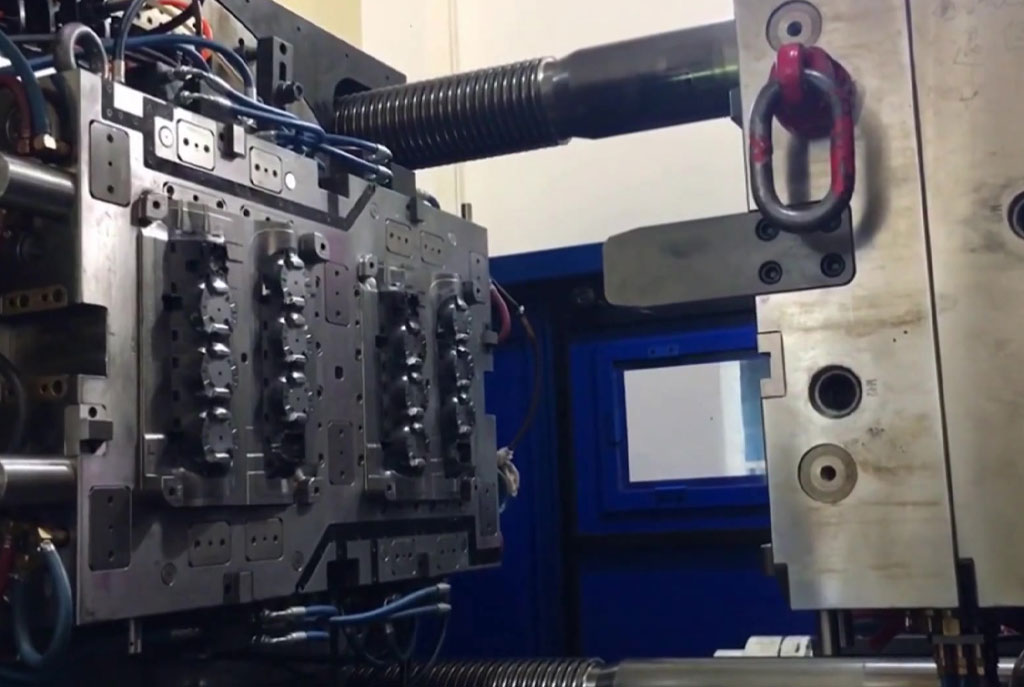

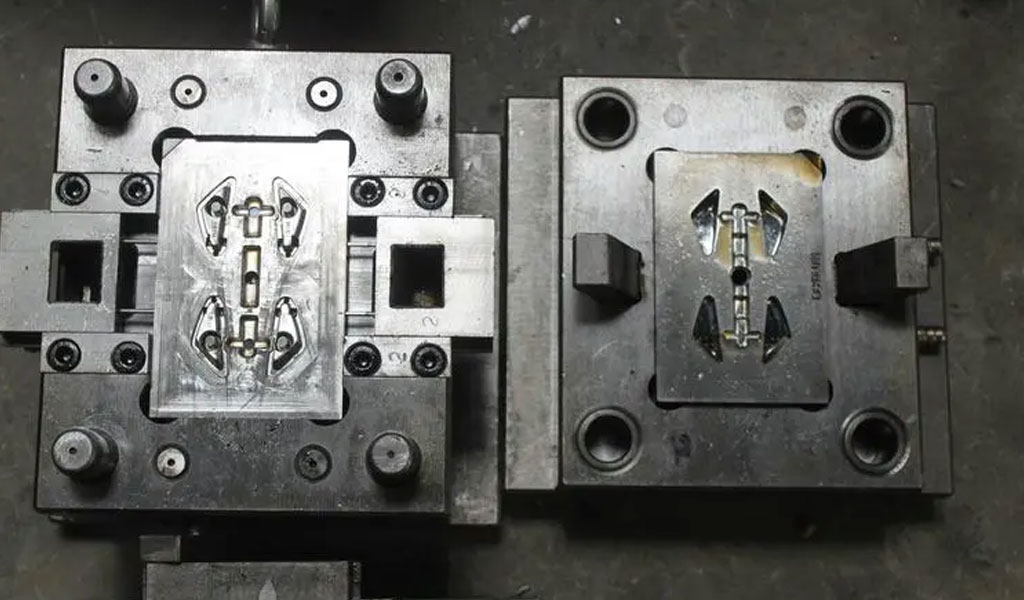

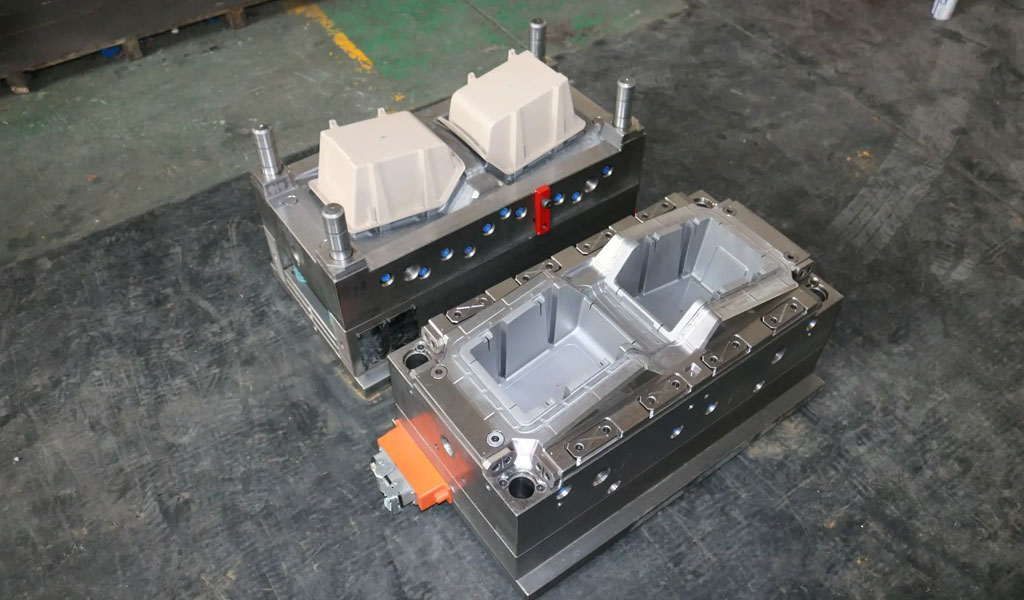

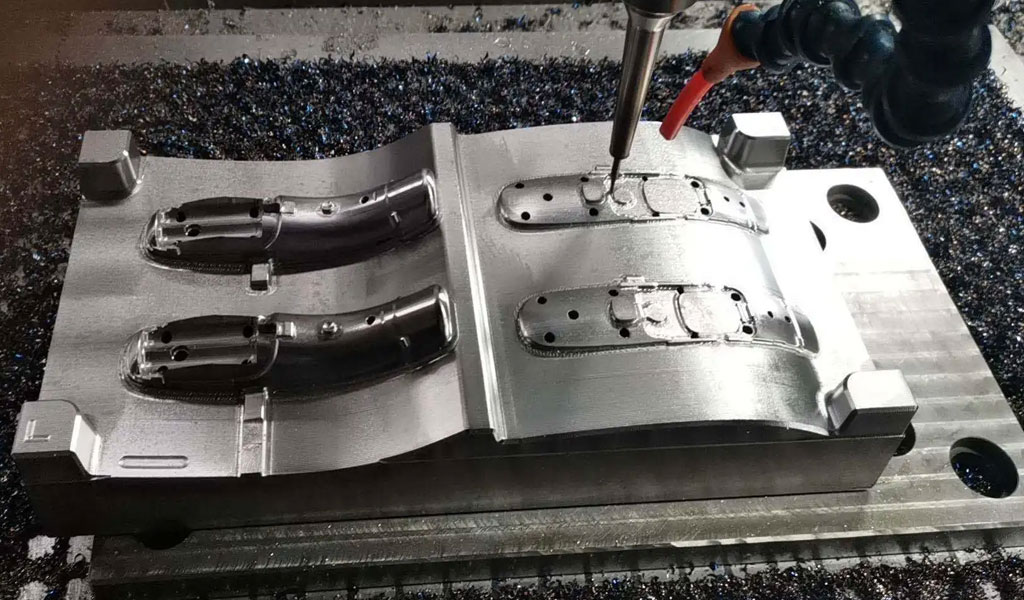

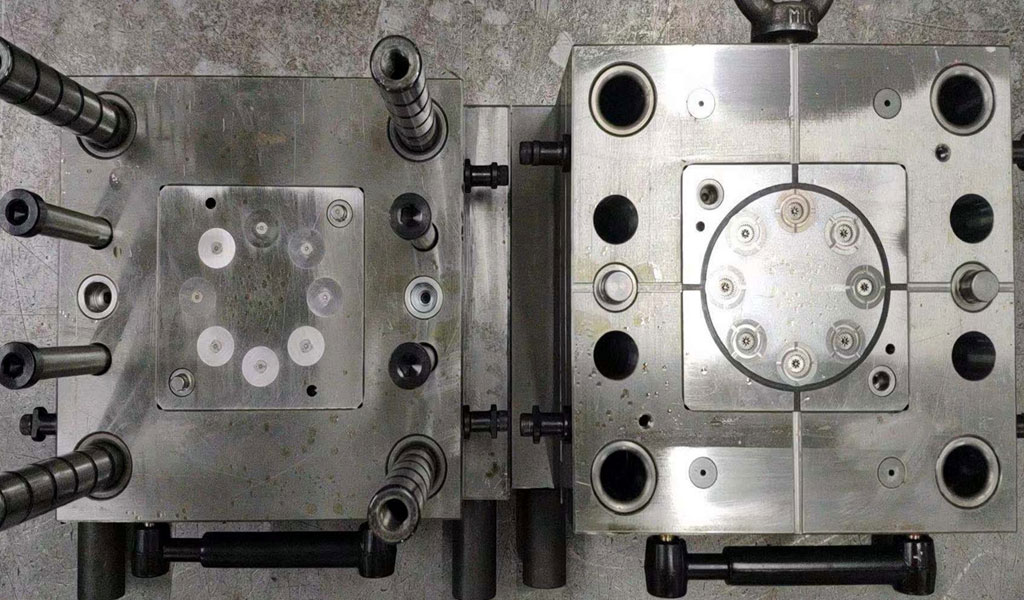

Be-Cu stands as a distinguished craftsman in the realm of multi-cavity precision injection molds. Our establishment boasts an immaculate and orderly environment, with every element meticulously managed.

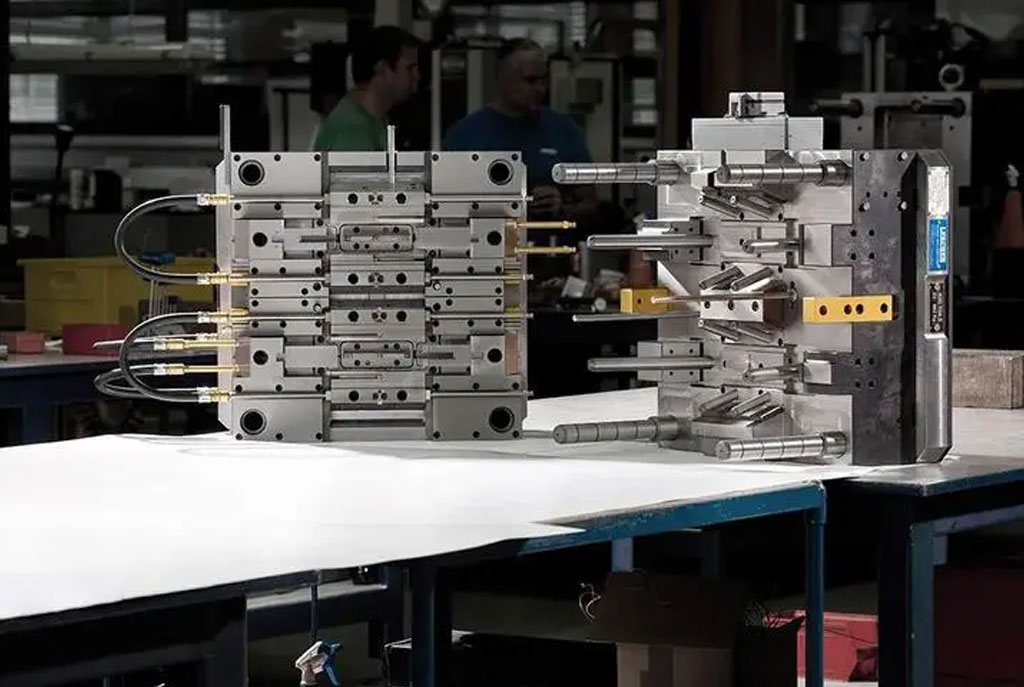

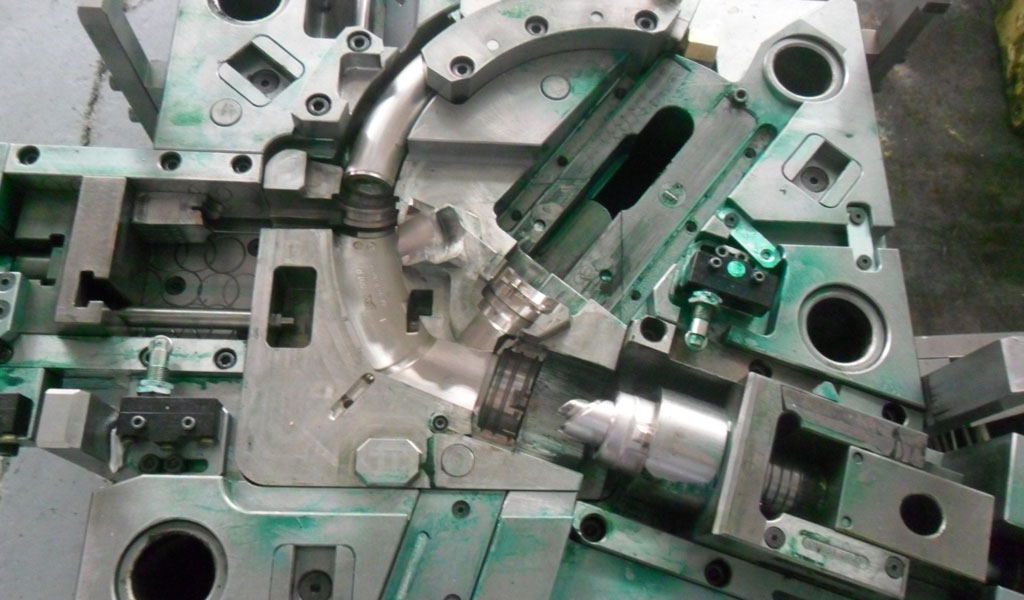

Our repertoire includes single or multi-cavity, stack, unscrewing, multi-shot, industrial, retail container, thin wall, and injection molds. We cater to both prototype and production runs, whether low or high volume, with clamping forces ranging from 15 to 3,000 tons.

We will test the molds several times. This is to check for any defects. We want to ensure high quality, durability, and a long-lasting lifetime in massive production. Pursuant to this commitment to quality, BE-CU China Mold Company has attained the ISO 9001:2015 quality certification.

Best Plastic Injection Molding Material

Our capabilities extend to molding various materials, such as acetal, acrylic, microcellular, polycarbonate, polyester, polypropylene, polystyrene, nylon 6, HDPE, LDPE, LCP, ABS, PBT, PEEK, PET, PLA, PPS, Ultem®, and thermoplastic elastomers. Alongside this, we offer secondary services including hot stamping, machining, flushing, engineering, and inspection.

Our clientele spans diverse industries, from electronics and aerospace to automotive, construction, communication, defense, military, medical, and optical sectors. Adhering to RoHS compliance, we ensure our practices meet stringent standards.

At Be-Cu, we employ the pinnacle of technology, utilizing only the most advanced software and hardware systems to maintain impeccable quality in our plastic molds. Our factory thrives with over 200 dedicated staff members, each a master of their craft, ensuring every aspect of the injection mold-making process is expertly handled. This team, chosen with precision, drives our growth and assures our customers receive superior quality products.

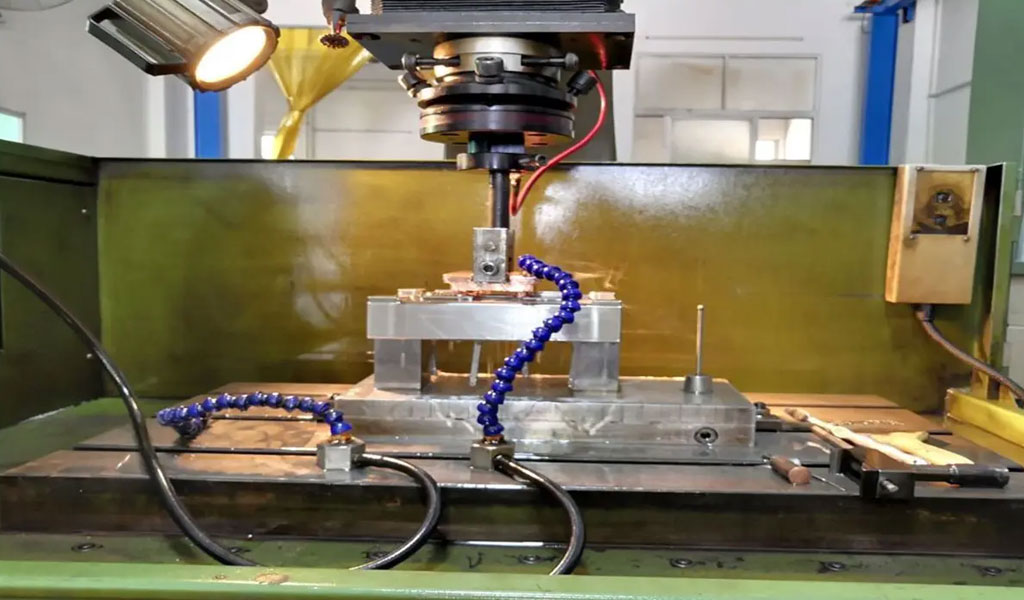

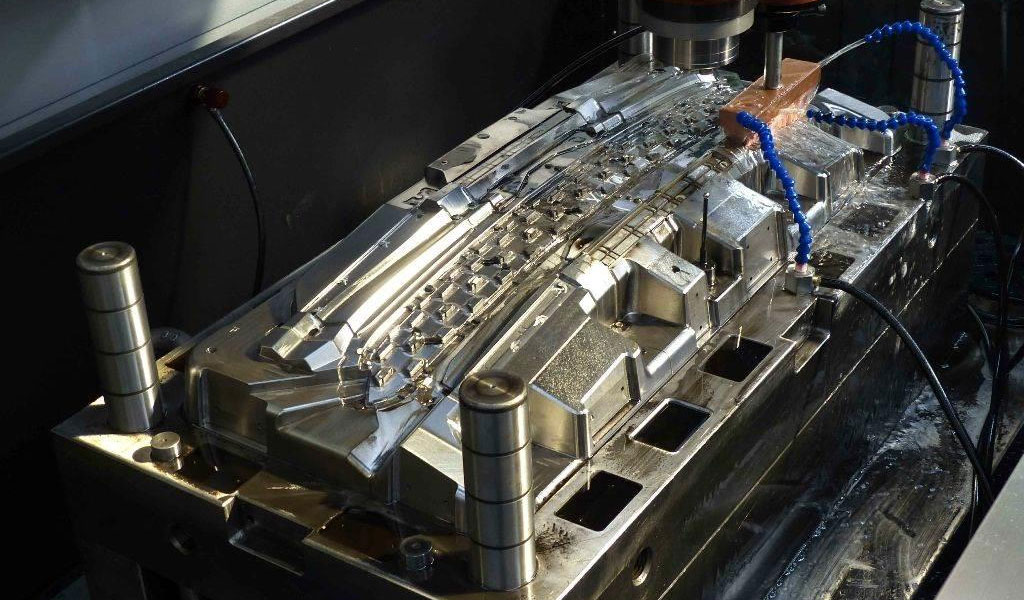

We pride ourselves on our High-speed FANUC CNC machine, a marvel imported directly from Japan, capable of over 24,000 rotations per minute. Additionally, we house two large CNC machines with over 2-meter strokes and fully automated three-coordinate measuring (CMM) machines, ensuring our processes are swift, efficient, and precise. This cutting-edge equipment, combined with our professional team, enables us to meet and exceed our goals.

Quality Assurance You Can Count On

To make good plastic mould and meet our customers required we have tight quality control procedures, even thought still not perfection but we are learning from our customers feed back and improve it from time to time, our customer will be satisfied by doing those quality control systems.This is emphasized by our ISO 9001:2008 Certification.Procedures as below.

- Tool drawing Design review before sending out to customer

- Tool drawing version updated in time to insure customer will have the latest version when sending out document with mold

- Design validation and verification

- Incoming inspection for all of row material

- First mold trial Inspection

- Checking electrodes by CMM easurement machine before EDM

- Full dimensions measurement report after T1

- Dimension adjustment inspection before next mold trial

- Coordinate Measuring Machine (CMM)

- Projector machine

All our engineers are proficient in English, guaranteeing clear and effective technical communication, enriching the project experience. Even if one lacks expertise in plastic injection molds and part design, our team is poised to guide and meticulously consider every detail on your behalf, ensuring your project’s smooth and successful execution.With your 3D or CAD file in hand, we will design the best mold for your product. One of our accomplished designers will work with you to adjust the type of material you would like for your specific application.

Leading Cases Of Plastic Injection Mold Making

Along with the widespread use of injection technology in various industries, there are many unique injection technologies emerging for different types of products. Since these techniques are able to enhance the product’s quality and efficiency, they are applied in furniture, automobile, electric appliance and many other industries.

BE-CU deeply develops the technologies of these new areas and has a good command of solutions like In-Mould Labeling, Thin Wall Molding, Multi-Shot Molding and Stack Molding, etc. We are confident to provide our customers with reliable and high-cost performance molds.

Two-color injection mold

Transparent Material Injection Mold

Daily Product Injection Mold

Large Automotive Bumper Injection Mold

Medical Parts Plastic Injection Mold

Forehead Thermometer Enclosure Injection Mold

Electric Bicycle Helmet Injection Mold

ABS Plastic Injection Mold

Multi-Cavity Gear Injection Mold

Our Case Studies Gallery Of Injection Mold Parts And Components

Put Be-cu.com’ experience to work for all of your injection mold parts and components needs —from traditional injection mold parts to two color injection mold components . Are you looking for mold manufacturers in China? Contact us to get started on your journey with a Chinese injection mold manufacturer. Let us be your OEM and plastic injection molding company in China. Send us an email to get a price now.

-

Precision Grinding Tungsten Steel Mold Parts

-

Special-Shaped Non-Standard Medical Device Needles

-

High-Speed Steel (HSS) Die Punching Needles

-

Precision Tungsten Copper Alloy Eccentric Insert

-

5 Axis CNC Machining Spiral Bevel Gear Mold

-

Small Precision Injection Molding Inserts

-

Non-Standard Position Component For Mold

-

CNC Machining Tungsten Cobalt Carbide Punch

-

Precision Wire Cutting Plastic Injection Mould Core