Bridge the Gap From Prototype to Production

Be-cu.com is fully capable of handling your urethane casting and silicone molding needs. With years of expertise in the field, we can fabricate your plastic parts to the highest standard, as well as cost-efficient and with fast turnarounds.

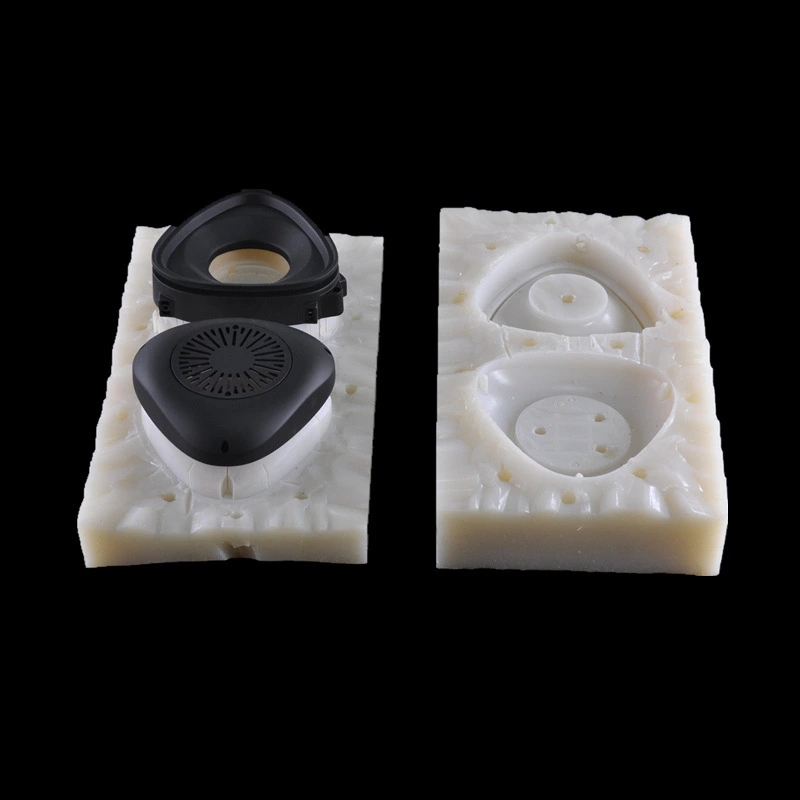

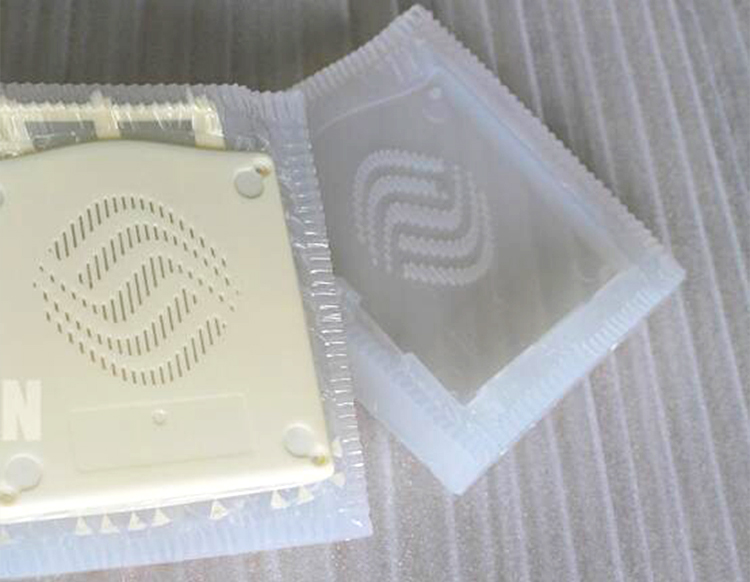

Vacuum casting refers to the use of the original sample plate to make a silica gel mold under vacuum, and the use of PU, silicone rubber, polyester, abs and other raw materials for pouring under vacuum, so as to reproduce the same photocopies as the original sample plate.Contact us today for more information about our vacuum casting services.

The Advantages Of Vacuum Casting

- No need to invest high initial cost in mold manufacturing

- The vacuum casting has a high degree of reduction, requiring little or no post-processing

- Different vacuum casting polymer materials are available, and the required color can be prepared according to requirements

- The mold can be completed within a few days after the production of the front prototype

- The die strength can meet 50 times of production

- Glue coating enables plastics of different materials and hardness to be integrally formed

Custom Manufacturer Of Vacuum Urethane Castings And Silicone Castings

With urethane often being used to mimic or replace injection molded components,Vacuum casting is very suitable for rapid engineering testing, design concept verification, sales and display.ISO 9001 and AS 9100 certified Manufacturer of prototype and short-run production vacuum castings.Be-cu. com’s manufacturing team is good at mold production, and can produce silica gel mold with strength of up to 60 products in a short time. The surface treatment of the products manufactured by duplicate mold is fine.The vacuum casting technology of Be-cu.com uses 3D printed templates to make silica gel molds in vacuum, and uses ABS, acrylic, PC, PA, silica gel, soft glue and other materials for pouring in vacuum, so as to clone the same copies as the original templates. A silicone mold can be used at least 20 times. It can also be used to reproduce or duplicate multiple high quality and relevant prototypes from a master model.Parts can be opaque, translucent or transparent depending upon application. Utilizes silicon molds for castings. Other services such as cnc machining, injection molding, extrusion, sheet metal prototyping, pressure die casting and surface finishing offered. Suitable for appearance models, engineering testing, market testing, proofing and display demos for investor pitches and trade shows. Serves the automotive, aerospace, electronics, energy and robotics industries.

| Typical Lead Time | Up to 20 parts in 15 days or less, depends on the part specification and volumes. |

| Accurate | Precision size: Locating Hole ±0.2mm, Mounting Hole ±0.4mm |

| Minimum Wall Thickness | To ensure that the mold is filled properly, a wall thickness of at least 0.75 mm is necessary. For best results, we recommend a wall thickness of at least 1.5 mm |

| Maximum Part Dimensions | Tolerance:±0.15mm. The maximum volume:2000*1200*1000mm |

| Typical Quantities | Up to 25 copies per mold (depending on the mold’s complexity and the casting materials) |

| Color & Finishing | Pigment is added to the liquid polyurethane prior to casting, custom painting and texture. |

| Road Test | The parts can reach the durability requirements of a 10,000km Road Test. |

Additive Services Of Vacuum Casting

- Tolerance: The tolerance of Vacuum Casting products mainly depends on the accuracy of prototype parts, the geometric structure of products and the selected manufacturing materials. Generally, 0.15% shrinkage is acceptable.

- Materials: Vacuum Casting can have hundreds of materials to choose from, which can achieve different design hardness and surface texture. The products of Vacuum Casting can be completely opaque or translucent, or completely transparent, which can meet various design requirements.

- Post-Processing: Be-cu.com provides a series of post-processing services to ensure that the products fully meet your expectations. Our post-treatment includes sand blasting, painting, polishing, water blasting, drilling, tapping and threaded holes, pad printing, silk screen, etc. We have a professional quality inspection team to check the products, and each project is visible in the production system and tracked by a specially assigned person.

Our Case Studies Gallery Of Vacuum Casting Parts

Our Vacuum Castings are designed to have high tear and impact strength, high heat deflection, flame retardancy and durometers from shore A 10 to shore D 80. Prototypes, short run and low production volume are available. Suitable for small and large parts.Currently, our vacuum casting parts are exported to America, Canada, Australia, United Kingdom, Germany, France, Sout Africa, and many other countries all over the world. We are ISO9001-2015 registered and also certified by SGS.

Our custom vacuum casting service provides durable and affordable silicone castings that meet your specifications for automotive, medical, aerospace, electronics, food, construction, security, marine, and more industries. Fast to send your inquiry or submit your drawings to get a free quote in the shortest time.Contact us or Email [email protected] to see how our people, equipment and tooling can bring the best quality for the best price for your vacuum casting project.

-

High Precision Vacuum Casting Rubber Prototype Parts

-

Vacuum Casting PP Soft Glue

-

Small Batch Manufacturing Of Plastic Parts

-

Acrylic Vacuum Casting Electronic Prototype Parts

-

Vacuum Casting Transparent Plastics Prototype Parts

-

5~25° Test Colored Transparent Soft Rubber Watchband

-

Vacuum Urethane Casting With Clad Metal

-

Soft Rubber Vacuum Casting Toy Silicone Tire

-

5~25° Vacuum Casting ABS Headphone Box

-

Vacuum Casting Custom Automotive Parts

-

Small Batch Vacuum Casting Resin Prototype

-

Urethane Casting Black Nylon Electronic Prototype Parts

What Is Vacuum Casting

The vacuum casting is to use the original template to make a silica gel mold under vacuum, and use PU or other materials to cast under vacuum, so as to clone the same replica as the original, which is more resistant to high temperature and has better strength and hardness than the original template.The vacuum casting will not damage the original, and the copied product has excellent surface treatment effect.The technology of vacuum urethane casting can be used for two purposes:

- Small batch manufacturing of rapid prototyping;

- Change the material; The prototype parts carved with gypsum putty can be changed to PU or POLY materials that are easy to be processed later through copying, or ABS materials can be changed to materials with special requirements (such as those requiring transparency, high temperature resistance, high strength, or rubber characteristics).

Vacuum Casting Process – The Detail Of Vacuum Casting

Small batch customization of vacuum casting not only has low production cost, but also has fast delivery time, which can be delivered in only 3 days