Aluminum alloys have become indispensable in various industries due to their exceptional combination of strength, durability, and versatility. Among the myriad of aluminum alloys available, 6063 aluminum stands out as a preferred choice for a wide range of applications. This article will delve deep into the properties, characteristics, manufacturing processes, and diverse applications of 6063 aluminum, providing a comprehensive understanding of why this alloy is a fundamental player in the modern world.

View More Articles:

Chapter 1: Understanding Aluminum Alloys

Aluminum alloys, like 6063 aluminum, are the backbone of various industries, owing their popularity to a unique combination of properties. 6063 is aluminum alloy, and 6063 is the number assigned by the company according to the product model. 6063 aluminum alloy is widely used in the framework of aluminum doors, windows and curtain walls.This chapter will provide a comprehensive understanding of aluminum alloys, the alloying process, and introduce 6063 aluminum as a notable member of this family.

1.1. Aluminum: A Brief Overview

Aluminum, symbolized as Al and possessing the atomic number 13, is one of the most abundant elements on Earth. It was discovered in the early 19th century and has since played a pivotal role in various fields. In this section, we will explore the historical background, abundance, and extraction of aluminum, as well as its key properties.

Historical Background

Aluminum’s history is a tale of intrigue and rarity. Once considered more valuable than gold, aluminum was a precious metal in the 18th century, with Emperor Napoleon III even using it for cutlery at state banquets. It wasn’t until the 19th century that a cost-effective method for aluminum extraction was developed, leading to its widespread use.

Abundance and Extraction

Despite its early scarcity, aluminum is one of the most abundant elements in the Earth’s crust, constituting about 8% of its mass. It primarily exists in the form of bauxite, a reddish-brown ore. The extraction process involves refining bauxite into aluminum oxide, followed by electrolytic reduction to obtain pure aluminum metal.

Key Properties of Aluminum

Aluminum boasts a remarkable set of properties that make it a material of choice across industries:

- Low Density: Aluminum is lightweight, with a density approximately one-third that of steel. This property makes it ideal for applications where weight reduction is critical, such as aerospace and automotive industries.

- Excellent Corrosion Resistance: Aluminum naturally forms a protective oxide layer on its surface, which shields it from corrosion. This attribute makes it suitable for outdoor and marine applications.

- Good Thermal and Electrical Conductivity: Aluminum conducts heat and electricity efficiently, making it valuable in heat sinks, electrical conductors, and various thermal management applications.

- Malleability and Ductility: Aluminum is highly malleable and ductile, allowing it to be easily formed into various shapes and sizes, making it a top choice for extrusion and forming processes.

1.2. Alloying Aluminum

Pure aluminum has excellent properties, but alloying it with other elements can enhance its characteristics for specific applications. This section delves into the alloying process, different types of aluminum alloys, and the significance of 6000-series alloys.

The Role of Alloying Elements

Alloying involves adding small amounts of other elements to aluminum to improve its properties. Common alloying elements include copper, magnesium, silicon, and zinc. These elements can enhance strength, hardness, corrosion resistance, and other desirable properties.

Types of Aluminum Alloys

Aluminum alloys are categorized into several series, with each series designed for particular purposes. The 1000, 2000, 3000, 4000, 5000, 6000, 7000, and 8000 series alloys cover a wide range of applications. For instance, the 1000 series is primarily used for pure aluminum, while the 6000 series is known for its excellent extrudability and formability, making it suitable for architectural and structural applications.

6000-Series Alloys

The 6000 series of aluminum alloys are some of the most versatile and widely used alloys. They are known for their excellent combination of strength, corrosion resistance, and formability. Within this series, 6063 aluminum stands out as an alloy of particular interest. In the following section, we will shine a spotlight on 6063 aluminum, exploring its composition, physical properties, mechanical properties, and corrosion resistance.

1.3. Spotlight on 6063 Aluminum

6063 aluminum is a remarkable alloy with a wide range of applications across industries. In this section, we will take a closer look at the composition and alloying elements of 6063 aluminum, its physical properties, mechanical properties, and corrosion resistance.

Composition and Alloying Elements

6063 aluminum is primarily composed of aluminum (Al), with key alloying elements such as silicon (Si) and magnesium (Mg). The composition of 6063 aluminum is finely tuned to achieve specific mechanical and thermal properties while maintaining excellent corrosion resistance.

Physical Properties

6063 aluminum exhibits several noteworthy physical properties, including its density, melting point, and thermal conductivity. Understanding these properties is crucial for determining its suitability for various applications.

Mechanical Properties

The mechanical properties of 6063 aluminum, including its tensile strength, yield strength, and elongation, make it an ideal choice for structural and extrusion applications. We will explore how these properties contribute to its performance in practical use.

Corrosion Resistance

One of the standout features of 6063 aluminum is its resistance to corrosion. This section will detail the mechanisms behind this resistance, highlighting its durability in challenging environments.

In the subsequent chapters of this article, we will delve even deeper into the manufacturing processes, applications, environmental considerations, and future prospects of 6063 aluminum, providing a comprehensive exploration of this versatile alloy.

All About 6063 Aluminum Properties, Materials Tables chart

6063 aluminum is a commonly used alloy in the 6xxx series of aluminum alloys, known for its excellent combination of mechanical properties, corrosion resistance, and versatility. It is often used in various structural and architectural applications, such as extrusions for window frames, doors, and various other profiles. Here’s some information about 6063 aluminum properties, along with a materials table chart:

Chemical Composition of 6063 Aluminum Alloy:

The chemical composition of 6063 aluminum typically includes:

- Silicon (Si): 0.20 – 0.60%

- Iron (Fe): 0.35%

- Copper (Cu): 0.10%

- Manganese (Mn): 0.10%

- Magnesium (Mg): 0.45 – 0.90%

- Chromium (Cr): 0.10%

- Zinc (Zn): 0.10%

- Titanium (Ti): 0.10%

- Other elements: 0.05% each, 0.15% total maximum

Mechanical Properties of 6063 Aluminum:

- Tensile Strength: 186 MPa (27,000 psi)

- Yield Strength: 145 MPa (21,000 psi)

- Elongation: 12%

- Brinell Hardness: 60 HB

Physical Properties of 6063 Aluminum:

- Density: 2.70 g/cm³ (0.0975 lb/in³)

- Melting Point: 595°C (1,103°F)

- Thermal Conductivity: 201 W/m·K (116 BTU·in/ft²·hr·°F)

- Electrical Conductivity: 33.6 MS/m (20% IACS)

Thermal Properties of 6063 Aluminum:

- Coefficient of Thermal Expansion: 23.5 x 10^-6/°C (13.0 x 10^-6/°F)

- Specific Heat Capacity: 897 J/kg·K (0.214 BTU/lb·°F)

Corrosion Resistance:

6063 aluminum alloy has good resistance to atmospheric corrosion, making it suitable for outdoor applications without the need for additional protective coatings. However, it is not as corrosion-resistant as some other aluminum alloys like 6061.

Weldability:

6063 aluminum is readily weldable using various techniques, including TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), and other welding methods.

Machinability:

6063 aluminum alloy has good machinability, and it can be easily cut, drilled, and shaped using conventional machining processes.

6063 Aluminum Material Properties Table Chart:

Here’s a simplified materials properties table chart for 6063 aluminum:

| Property | Value |

|---|---|

| Tensile Strength | 186 MPa (27,000 psi) |

| Yield Strength | 145 MPa (21,000 psi) |

| Elongation | 12% |

| Density | 2.70 g/cm³ |

| Melting Point | 595°C (1,103°F) |

| Thermal Conductivity | 201 W/m·K |

| Electrical Conductivity | 33.6 MS/m |

| Coefficient of Expansion | 23.5 x 10^-6/°C |

| Specific Heat Capacity | 897 J/kg·K |

| Corrosion Resistance | Good (atmospheric) |

| Weldability | Excellent |

| Machinability | Good |

Please note that the specific mechanical properties of 6063 aluminum can vary depending on the temper (heat treatment) of the material, and these values are approximate averages. For precise data, it’s recommended to consult material specifications or testing results for the specific 6063 alloy and temper you intend to use.

Chapter 2: Manufacturing and Processing of 6063 Aluminum

6063 aluminum’s journey from raw materials to finished products involves a series of intricate processes. In this chapter, we will explore the manufacturing and processing steps that transform raw materials into the versatile 6063 aluminum alloy, including extraction, alloying, casting, extrusion, and fabrication techniques.

2.1. Raw Material Extraction

The production of 6063 aluminum begins with the extraction of raw materials, primarily bauxite, and involves several critical steps.

Bauxite to Aluminum Oxide

- Bauxite Mining: Bauxite, a reddish-brown ore, is mined from the Earth’s crust, primarily in tropical and subtropical regions. It is rich in aluminum minerals, including gibbsite, boehmite, and diaspore.

- Bauxite Refining: The mined bauxite undergoes refining to extract aluminum oxide, also known as alumina. This process, known as the Bayer process, involves crushing, grinding, and refining bauxite into a white powder—alumina.

Electrolytic Reduction

Once alumina is obtained, the next step is the extraction of pure aluminum through the process of electrolytic reduction.

Hall-Héroult Process: Alumina is dissolved in molten cryolite (sodium aluminum fluoride) and subjected to an electrical current in a large electrolytic cell. This process, known as the Hall-Héroult process, separates aluminum from oxygen. As a result, aluminum metal is produced at the cathode, while oxygen is released at the anode.

2.2. Alloying and Casting

6063 aluminum, like many aluminum alloys, is produced by alloying pure aluminum with specific elements to enhance its properties.

Melting and Alloying

- Melting: Pure aluminum is melted in a furnace, typically using natural gas or electricity as the heat source. The temperature required for melting aluminum is around 660.3°C (1220.5°F).

- Alloying Elements: During melting, alloying elements such as silicon (Si) and magnesium (Mg) are added in precise proportions to create the 6063 alloy. These elements impart desirable properties, such as improved strength and corrosion resistance.

Casting Methods

- Direct Chill (DC) Casting: In DC casting, the molten aluminum alloy is poured into a water-cooled mold. This rapid cooling process produces a cast billet with a fine grain structure, ideal for subsequent extrusion.

- Continuous Casting: Continuous casting involves a continuous process of solidifying the alloy as it moves through a water-cooled mold. This method is efficient for mass production of billets.

Billet Production

The resulting cast billets are typically cylindrical or rectangular in shape and serve as the raw material for the extrusion process. The size and dimensions of the billets can vary depending on the intended application of the 6063 aluminum.

2.3. Extrusion Process

Extrusion is a fundamental step in the production of 6063 aluminum and involves shaping the aluminum alloy into specific profiles or shapes.

Extrusion Basics

- Die and Extruder: The process begins with a cylindrical billet being heated to a suitable temperature in an extrusion oven. The heated billet is then placed in an extrusion press.

- Extrusion Process: The press forces the heated billet through a specially designed die, which imparts the desired shape to the aluminum. This process is highly versatile and can create a wide range of profiles, from simple rods to complex cross-sections.

6063 Alloy Extrusion

6063 aluminum is particularly well-suited for extrusion due to its excellent formability and extrudability. Its ability to maintain its mechanical properties during extrusion makes it a popular choice for applications requiring intricate profiles and designs.

Heat Treatment and Aging

To enhance the mechanical properties of extruded 6063 aluminum, a heat treatment process is often applied. This involves heating the extruded profiles to specific temperatures and then subjecting them to controlled cooling. The heat treatment process can significantly improve the alloy’s strength and hardness, making it suitable for a wide range of applications.

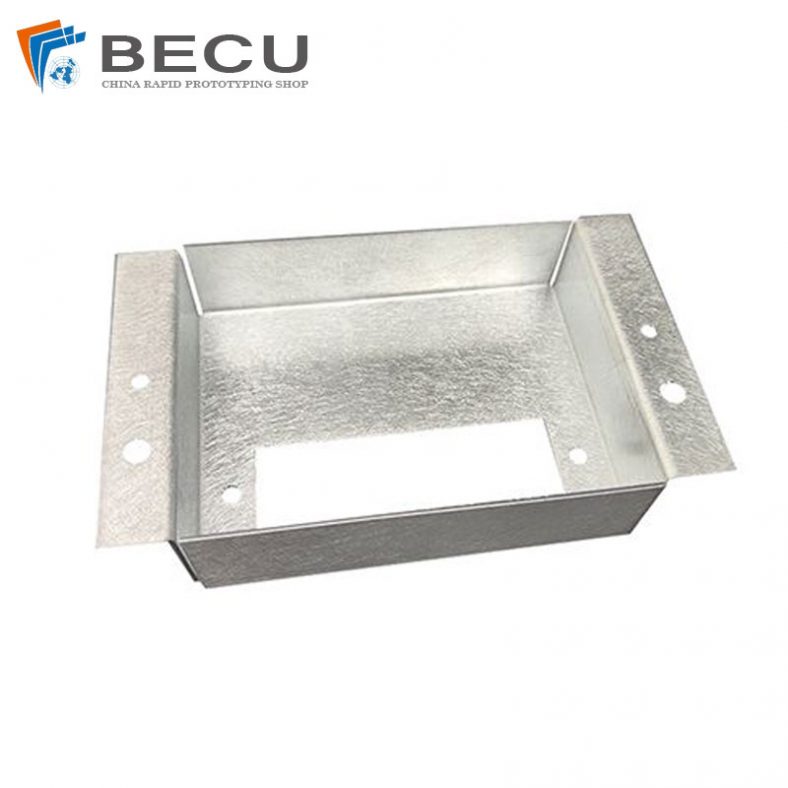

2.4. Fabrication Techniques

6063 aluminum profiles may undergo further processing to meet specific requirements for various applications.

Machining

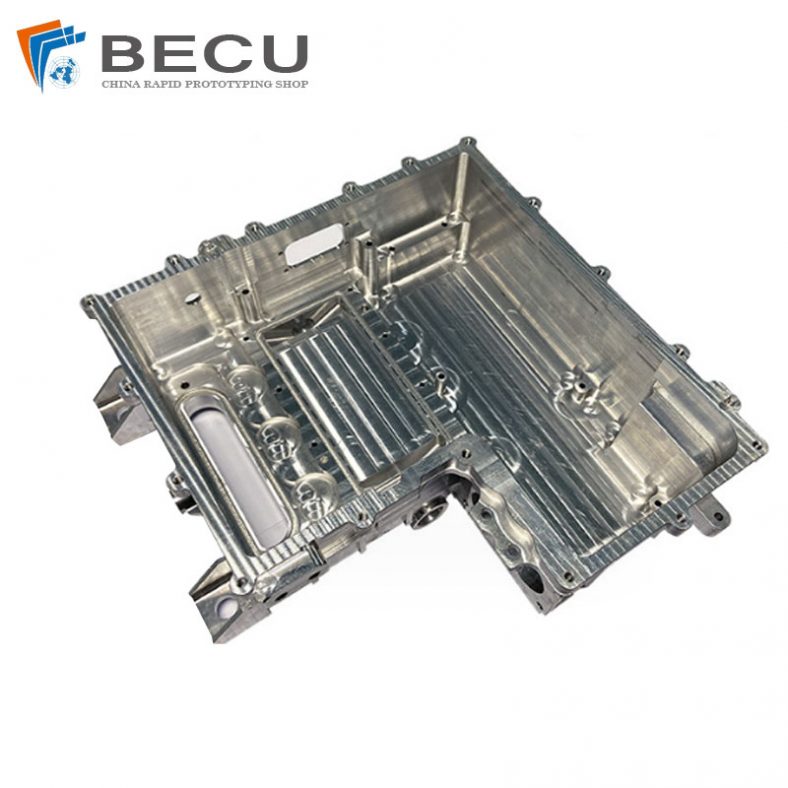

CNC Machining: Computer Numerical Control (CNC) machining is used to precision-cut, drill, or mill aluminum profiles to exact specifications. 6063 aluminum cnc machining technique is crucial for creating components with tight tolerances.

Welding and Joining

TIG and MIG Welding: Tungsten Inert Gas (TIG) and Metal Inert Gas (MIG) welding are commonly used methods to join 6063 aluminum components. These processes offer strong, reliable welds suitable for structural applications.

Surface Finishing

- Anodizing: Anodizing is an electrochemical process that forms a protective oxide layer on the surface of aluminum, enhancing its corrosion resistance and providing a wide range of color options.

- Powder Coating: Powder coating involves applying a dry powder to the aluminum surface and then curing it with heat. This method provides a durable, attractive finish.

In conclusion, the manufacturing and sheet metal fabrication of aluminum 6063 alloy involve a series of meticulously controlled steps, starting with raw material extraction and culminating in the production of versatile aluminum profiles. These processes, combined with extrusion and various fabrication techniques, allow 6063 aluminum to fulfill a multitude of roles across diverse industries.

Chapter 3: Properties and Performance of 6063 Aluminum

In this chapter, we will explore the mechanical, thermal, electrical, and corrosion resistance properties of 6063 aluminum, shedding light on its outstanding performance characteristics.

3.1. Mechanical Strength

6063 aluminum exhibits remarkable mechanical strength properties, making it suitable for a wide range of applications.

Tensile Strength

Tensile strength is the maximum stress that a material can withstand while being stretched or pulled before necking, which is when the specimen’s cross-section starts to significantly contract. For 6063 aluminum, the tensile strength typically falls within the range of 186-241 MPa (27,000-35,000 psi). This makes it ideal for components requiring structural integrity and load-bearing capabilities.

Yield Strength

Yield strength represents the amount of stress at which a material begins to deform plastically, but it has not yet reached the point of failure. 6063 aluminum generally has a yield strength ranging from 90 to 145 MPa (13,000 to 21,000 psi). This property ensures that the material can return to its original shape after the applied load is removed, preventing permanent deformation.

Impact Resistance

6063 aluminum also exhibits good impact resistance, allowing it to absorb and dissipate energy when subjected to sudden forces or shocks. This property is valuable in applications where structural components may experience dynamic loading, such as in automotive parts and architectural elements.

3.2. Thermal Properties

Thermal properties are crucial when considering the use of 6063 aluminum in applications involving heat management and thermal conductivity.

Thermal Conductivity

6063 aluminum possesses excellent thermal conductivity, with a value typically ranging between 160 and 205 W/m·K. This high thermal conductivity makes it an ideal choice for heat sinks, where it efficiently dissipates heat generated by electronic components, ensuring their proper functioning and longevity.

Coefficient of Thermal Expansion

The coefficient of thermal expansion (CTE) measures how a material’s dimensions change with temperature variations. 6063 aluminum has a CTE of approximately 23.6 µm/m·K, which is relatively low. This low CTE minimizes the risk of thermal expansion-related issues, such as warping or cracking, in applications subjected to temperature fluctuations.

Heat-Treatment Considerations

Heat treatment can further enhance the mechanical properties of 6063 aluminum. The process involves heating the material to specific temperatures and then cooling it in a controlled manner. Heat treatment can improve the alloy’s hardness, tensile strength, and corrosion resistance. Precise heat-treatment procedures must be followed to achieve the desired results and meet application-specific requirements.

3.3. Electrical Conductivity

6063 aluminum exhibits good electrical conductivity, making it suitable for various electrical and electronic applications.

Applications in Electrical Engineering

Due to its conductivity and other favorable properties, 6063 aluminum is utilized in electrical engineering for components such as:

- Busbars: Aluminum busbars made from 6063 alloy are commonly used to distribute electrical current efficiently in electrical panels and switchgear.

- Conductors: In some electrical applications, 6063 aluminum is used as a conductor material due to its combination of electrical conductivity and lightweight properties.

3.4. Corrosion Resistance

Corrosion resistance is a critical property for many applications, particularly when exposed to harsh environments.

Resistance to Atmospheric and Chemical Corrosion

6063 aluminum exhibits excellent resistance to atmospheric corrosion. The naturally occurring aluminum oxide layer that forms on its surface acts as a protective barrier, preventing further oxidation and corrosion. This property makes it suitable for outdoor applications where exposure to moisture and atmospheric pollutants is a concern.

In addition to atmospheric corrosion resistance, 6063 aluminum also has good resistance to chemical corrosion, particularly when compared to other metals. It can withstand exposure to a variety of common chemicals, making it an excellent choice for applications where chemical resistance is required.

Protective Coatings

To further enhance its corrosion resistance and provide additional aesthetic options, 6063 aluminum profiles are often treated with protective coatings. Anodizing, for instance, creates a thicker, more durable oxide layer on the surface, offering increased protection against corrosion while allowing for a variety of colors and finishes.

6063 aluminum exhibits a range of exceptional properties and performance characteristics. Its mechanical strength, thermal conductivity, electrical conductivity, and corrosion resistance make it an ideal choice for various applications across industries. Whether it’s in architectural elements, heat sinks, electrical components, or outdoor structures, 6063 aluminum consistently delivers the performance needed to excel in demanding environments.

Chapter 4: Applications of 6063 Aluminum

6063 aluminum’s versatility and exceptional properties have positioned it as a material of choice in numerous industries. In this chapter, we will explore its wide-ranging applications, from architecture and construction to consumer goods, highlighting the reasons behind its popularity in each sector.

4.1. Architecture and Construction

6063 aluminum plays a pivotal role in modern architecture and construction due to its combination of strength, durability, and aesthetics.

Structural Components

- Beams and Columns: In commercial and residential buildings, 6063 aluminum is used for structural components such as beams and columns. Its high strength-to-weight ratio allows for efficient load-bearing while reducing the overall weight of the structure.

- Balustrades and Handrails: Its corrosion resistance and pleasing appearance make it an ideal choice for balustrades and handrails in both interior and exterior applications.

Window Frames and Doors

- Window Frames: 6063 aluminum is frequently employed for window frames due to its excellent corrosion resistance, which ensures long-term durability even in harsh weather conditions.

- Doors: The lightweight nature of 6063 aluminum makes it suitable for door frames, where its strength and ease of fabrication allow for the creation of both functional and aesthetically pleasing doors.

Curtain Walls and Facades

Curtain walls, often seen in modern skyscrapers and large commercial buildings, benefit from the lightweight and corrosion-resistant properties of 6063 aluminum. It enables architects to design intricate facades while maintaining structural integrity and energy efficiency.

4.2. Automotive Industry

The automotive industry relies on 6063 aluminum for various components that contribute to vehicle performance, safety, and efficiency.

Extruded Automotive Parts

- Bumper Beams: 6063 aluminum is utilized for manufacturing bumper beams, contributing to crashworthiness while minimizing vehicle weight.

- Body Structure: Automakers incorporate 6063 aluminum into the body structure to improve fuel efficiency by reducing overall weight.

Heat Exchangers

In the automotive sector, heat exchangers made from 6063 aluminum are used in radiators and air conditioning systems. The alloy’s high thermal conductivity facilitates efficient heat transfer, ensuring engine cooling and passenger comfort.

Lightweighting Initiatives

As automakers strive to meet stringent fuel efficiency and emissions standards, lightweighting has become a priority. 6063 aluminum’s lightweight properties are instrumental in achieving these goals, as it helps reduce the overall weight of vehicles, leading to improved fuel economy.

4.3. Electronics and Electrical Engineering

6063 aluminum finds applications in electrical and electronic systems, where its properties meet the demands of these specialized industries.

Heat Sinks

Electronic components generate heat during operation, which can affect performance and lifespan. 6063 aluminum’s high thermal conductivity makes it an ideal material for cnc machining heat sinks. These heat sinks dissipate heat, preventing overheating and ensuring electronics operate at optimal temperatures.

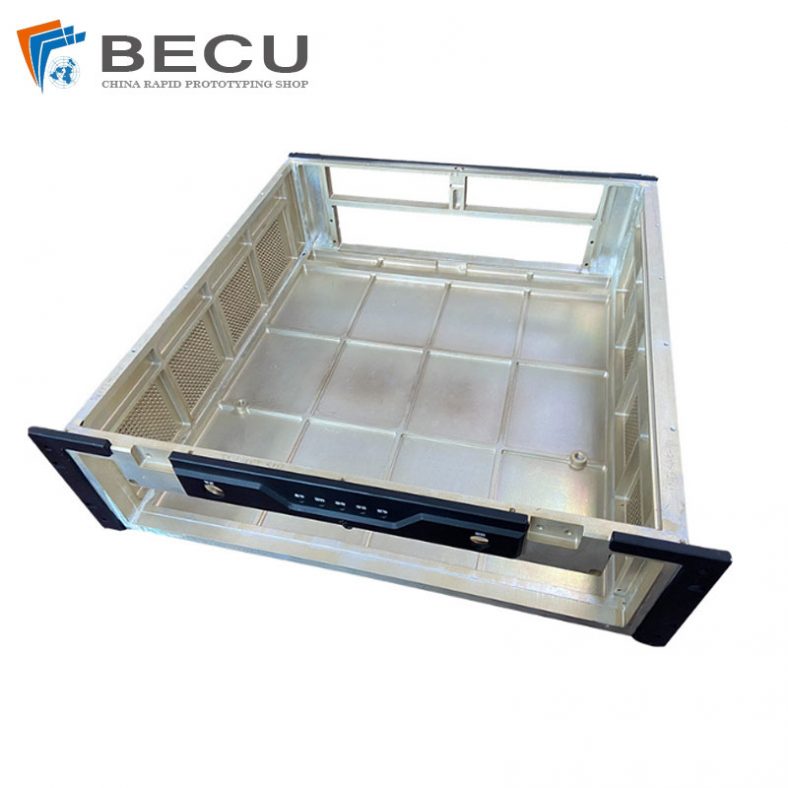

Electrical Enclosures

6063 aluminum is used to manufacture electrical enclosures that protect sensitive equipment from environmental factors, such as dust, moisture, and temperature fluctuations. Its corrosion resistance is particularly valuable in outdoor enclosures.

Busbars and Conductors

Aluminum busbars and conductors made from 6063 alloy offer a lightweight, cost-effective solution for electrical distribution. They excel in power transmission applications and are favored for their electrical conductivity.

4.4. Industrial and Manufacturing

6063 aluminum contributes to the efficiency and reliability of various industrial and manufacturing processes.

Conveyor Systems

In industrial settings, conveyor systems often utilize 6063 aluminum components. Its lightweight nature, corrosion resistance, and strength make it a practical choice for transporting materials and goods.

Pneumatic Systems

The manufacturing industry relies on pneumatic systems for automation and control. 6063 aluminum is commonly used in the construction of pneumatic system components, ensuring durability and corrosion resistance in demanding environments.

Material Handling Equipment

Material handling equipment, such as carts, racks, and shelves, benefits from 6063 aluminum’s lightweight, yet robust, characteristics. It facilitates the efficient movement and storage of materials in warehouses and manufacturing facilities.

4.5. Renewable Energy Sector

6063 aluminum plays a vital role in supporting the growth of renewable energy technologies.

Solar Panel Frames

Solar panels require frames that are both lightweight and durable. 6063 aluminum is an ideal choice, as it provides the structural support needed to secure solar panels while withstanding outdoor conditions.

Wind Turbine Components

In wind energy applications, 6063 aluminum is utilized for various components, including tower structures and nacelle components. Its strength and resistance to corrosion ensure the longevity and reliability of wind turbines.

Heat Exchangers for Geothermal Systems

Geothermal heating and cooling systems rely on heat exchangers to transfer thermal energy between the ground and a building’s HVAC system. 6063 aluminum’s thermal conductivity makes it an excellent choice for these heat exchangers, ensuring efficient energy transfer.

4.6. Consumer Goods

6063 aluminum enhances the performance and aesthetics of consumer goods.

Furniture

6063 aluminum is used in the manufacturing of lightweight, durable, and stylish furniture. Its corrosion resistance ensures that outdoor furniture remains in excellent condition even when exposed to the elements.

Bicycle Frames

Bicycle manufacturers opt for 6063 aluminum frames to create lightweight yet robust bikes. Cyclists benefit from its responsive handling and efficient power transfer.

Sporting Equipment

Sports equipment, such as golf club shafts and archery bows, leverages 6063 aluminum for its ability to provide the necessary strength and flexibility required for high-performance sports.

6063 aluminum’s versatility extends across various industries, from construction and automotive to electronics and renewable energy. Its exceptional properties, including strength, lightweight, corrosion resistance, and thermal conductivity, continue to make it a sought-after material for a wide array of applications. As industries evolve and strive for sustainability, 6063 aluminum remains a crucial element in driving innovation and meeting the demands of the modern world.

Chapter 5: Environmental Sustainability and Recycling

Environmental sustainability is a critical consideration in today’s world. In this chapter, we will explore the environmental impact of 6063 aluminum production and the importance of recycling this versatile material.

5.1. Environmental Impact of Aluminum Production

The production of aluminum, including 6063 alloy, has environmental implications primarily related to energy consumption and carbon emissions.

Energy Consumption

- Bauxite Mining and Refining: The extraction of aluminum from bauxite requires significant energy input, particularly in the refining stage. The Bayer process, used to extract alumina from bauxite, consumes substantial amounts of energy.

- Electrolytic Reduction: The Hall-Héroult process, which reduces alumina to aluminum metal, is highly energy-intensive. It requires large amounts of electricity, making it a major contributor to the energy footprint of aluminum production.

- Extrusion and Fabrication: While the extrusion and fabrication processes for 6063 aluminum consume energy, they are relatively more efficient compared to the initial production stages.

Carbon Footprint

- Greenhouse Gas Emissions: The energy-intensive processes involved in aluminum production result in significant greenhouse gas emissions. Carbon dioxide (CO2) is released during the extraction of alumina from bauxite and the reduction of alumina to aluminum metal.

- Transportation: The transportation of raw materials, such as bauxite and alumina, and finished aluminum products also contributes to the carbon footprint of the aluminum industry.

5.2. Aluminum Recycling

Recycling 6063 aluminum offers an environmentally responsible alternative to primary production, reducing energy consumption, greenhouse gas emissions, and the demand for virgin resources.

The Aluminum Recycling Process

- Collection: Aluminum recycling begins with the collection of aluminum products, such as beverage cans, window frames, and other aluminum components. These materials are gathered from various sources, including households, industries, and recycling centers.

- Sorting and Cleaning: Collected aluminum items are sorted to remove contaminants like plastic, glass, and other non-aluminum materials. Cleaning processes may also be employed to remove any remaining impurities.

- Melting and Purification: The sorted aluminum is then melted down to create aluminum alloy ingots. During this melting process, coatings and paints are burned off, and any remaining contaminants are separated. The result is high-purity aluminum suitable for recycling.

- Extrusion and Fabrication: Once recycled aluminum is in the form of ingots, it can be used in the same extrusion and fabrication processes as primary aluminum, creating new 6063 aluminum products.

Benefits of Recycling 6063 Aluminum

- Energy Savings: Recycling aluminum consumes significantly less energy compared to primary production. It is estimated that recycling aluminum saves up to 95% of the energy required to produce aluminum from bauxite. This energy efficiency contributes to a reduction in the carbon footprint of the aluminum industry.

- Resource Conservation: Recycling aluminum conserves valuable natural resources, such as bauxite and alumina. It helps reduce the need for mining and the associated environmental impact.

- Reduction in Emissions: Recycling aluminum leads to a substantial decrease in greenhouse gas emissions associated with primary production processes, particularly the energy-intensive electrolytic reduction of alumina.

- Economic Benefits: Recycling supports the aluminum industry by providing a consistent supply of raw material. It also generates economic value through the recycling process, creating jobs in collection, sorting, and recycling operations.

- Closed-Loop Recycling: Aluminum is highly amenable to closed-loop recycling, where the same material can be recycled repeatedly without significant degradation in quality. This closed-loop system reduces waste and environmental impact.

- Environmental Responsibility: Recycling aligns with corporate and societal environmental responsibility goals, demonstrating a commitment to sustainability and reducing the environmental footprint of aluminum products.

- Reduced Landfill Waste: By diverting aluminum products from landfills, recycling helps reduce the burden on waste disposal facilities and minimizes the environmental impact of landfilling.

6063 aluminum, like other aluminum alloys, is an excellent candidate for recycling due to its recyclability and the significant environmental benefits associated with aluminum recycling. Recycling not only conserves energy and resources but also reduces carbon emissions and supports a sustainable approach to aluminum production. As sustainability continues to gain prominence, recycling 6063 aluminum remains a crucial practice for minimizing the environmental impact of this versatile material while meeting the demands of various industries.

Chapter 7: Conclusion

In this concluding chapter, we summarize the key points discussed throughout this comprehensive exploration of 6063 aluminum and its significance in our world.

7.1. Summary of Key Points

We have examined 6063 aluminum in detail, uncovering its exceptional properties and versatile applications. Here are the main takeaways:

Properties and Characteristics of 6063 Aluminum:

- 6063 aluminum exhibits a unique combination of mechanical strength, thermal conductivity, electrical conductivity, and corrosion resistance.

- Its mechanical properties, including tensile strength and yield strength, make it suitable for structural and load-bearing applications.

- Remarkable thermal conductivity ensures its effectiveness in heat sinks and thermal management systems.

- Its electrical conductivity is a valuable asset in electrical engineering applications.

- Excellent corrosion resistance, both to atmospheric and chemical factors, enhances its durability in various environments.

Versatile Applications Across Industries:

- 6063 aluminum finds application in diverse sectors, including architecture, construction, automotive, electronics, industrial manufacturing, renewable energy, and consumer goods.

- Its use in structural components, window frames, curtain walls, and facades contributes to modern architecture’s aesthetics and durability.

- In the automotive industry, 6063 aluminum is instrumental in lightweighting initiatives and heat exchanger systems.

- Its thermal properties are essential for heat sinks in electronics, electrical enclosures, and busbars.

- Industrial applications, such as conveyor systems and pneumatic systems, benefit from its strength and corrosion resistance.

- In the renewable energy sector, 6063 aluminum supports solar panels, wind turbines, and geothermal systems.

- In the consumer goods industry, it provides lightweight, durable solutions for furniture, bicycle frames, and sporting equipment.

Environmental Considerations and Recycling:

- The production of aluminum, including 6063 alloy, has environmental implications, mainly related to energy consumption and carbon emissions.

- Recycling 6063 aluminum offers significant benefits, including energy savings, resource conservation, emission reduction, and economic value generation.

- A closed-loop recycling system ensures that the material can be reused repeatedly without significant degradation in quality, contributing to waste reduction and environmental sustainability.

7.2. The Ongoing Relevance of 6063 Aluminum

As we conclude our exploration of 6063 aluminum, it is crucial to recognize its enduring relevance:

A Material for the Present and Future:

- 6063 aluminum has firmly established itself as a material of choice in various industries, meeting the demands of modern applications.

- Its versatility, combining lightweight properties with strength and corrosion resistance, positions it as a critical resource for addressing contemporary challenges.

Opportunities and Challenges:

- The ongoing relevance of 6063 aluminum presents opportunities for innovation and sustainability.

- Innovations in alloy development, sustainable manufacturing practices, and integration with emerging technologies hold promise for enhancing its properties and expanding its applications.

However, challenges also lie ahead, including the need for responsible resource management, energy-efficient production, and continued commitment to recycling and sustainability.

In conclusion, 6063 aluminum, with its exceptional properties and diverse applications, remains at the forefront of materials shaping our world. Its journey from raw material extraction to recycling underscores its contribution to environmental responsibility and sustainability. As industries evolve and adapt to meet the demands of the present and future, 6063 aluminum continues to be a vital component in addressing these challenges and driving progress across a multitude of sectors.