In the realm of modern materials science, carbon fiber has emerged as a revolutionary substance with a wide range of applications across industries. Renowned for its exceptional strength-to-weight ratio, carbon fiber has gained prominence in sectors as diverse as aerospace, automotive, sports equipment, and even consumer electronics. This article delves into the performance advantages of carbon fiber products, exploring their unique properties, manufacturing processes, and the benefits they offer across various domains.

View More Articles:

Carbon Fiber: The Building Blocks

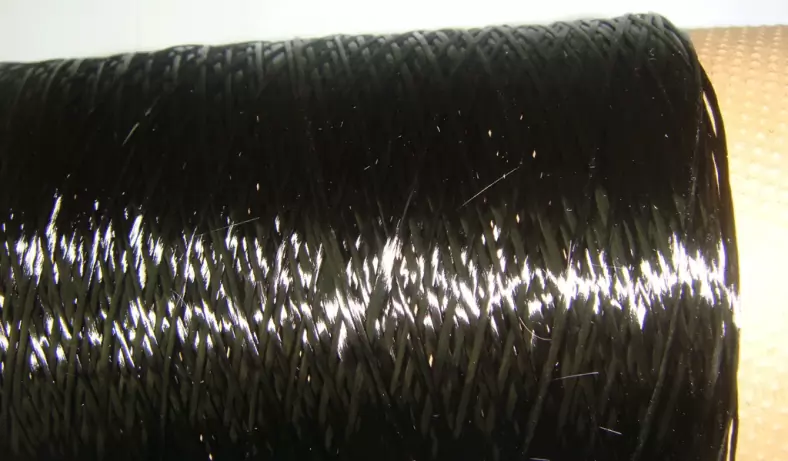

Carbon fiber is a composite material composed primarily of carbon atoms. Its exceptional strength originates from the alignment of these carbon atoms in a parallel manner, creating long, thin strands known as fibers. These fibers are then embedded in a matrix material, often a polymer resin, to form a composite. This intricate arrangement grants carbon fiber products remarkable mechanical properties that set them apart from traditional materials like steel or aluminum.

Exceptional Strength and Lightweight Design

One of the most significant advantages of carbon fiber products is their exceptional strength-to-weight ratio. This property stems from the unique arrangement of carbon atoms, which forms a strong, stable crystal lattice structure. As a result, carbon fiber products can exhibit tensile strengths that rival those of steel while being significantly lighter. This characteristic is particularly crucial in industries such as aerospace and automotive, where reducing weight while maintaining structural integrity is of paramount importance.

Stiffness and Flexibility

Carbon fiber’s inherent stiffness is another key advantage. Its high modulus of elasticity ensures that even slender carbon fiber components remain rigid and resistant to deformation under stress. This stiffness contributes to enhanced performance in applications such as sports equipment, where the precise transmission of forces is critical for optimal performance. Simultaneously, carbon fiber’s flexibility can be engineered through variations in fiber orientation and matrix materials, making it adaptable to various design requirements.

Corrosion Resistance

Unlike traditional materials like steel, carbon fiber is inherently corrosion-resistant. This quality is especially valuable in harsh environments where exposure to moisture, chemicals, or salt can compromise the integrity of conventional materials. In industries like marine engineering and offshore structures, carbon fiber’s resistance to corrosion extends the lifespan of components and reduces maintenance costs.

Fatigue Resistance

Carbon fiber products exhibit excellent fatigue resistance, which refers to their ability to withstand cyclic loading and unloading without experiencing material degradation. This property is pivotal in applications subjected to repetitive stress, such as aircraft wings during takeoff and landing or bicycle frames enduring continuous road vibrations. Carbon fiber’s fatigue resistance contributes to prolonged product lifecycles and improved reliability.

Thermal Conductivity

Carbon fiber boasts relatively low thermal conductivity, which makes it suitable for applications where thermal insulation is desirable. This property finds use in industries like electronics, where carbon fiber components can help manage heat dissipation, preventing overheating and maintaining optimal device performance.

Manufacturing Processes and Customization

The production of carbon fiber products involves several intricate steps. Initially, precursor materials like polyacrylonitrile (PAN) or pitch fibers are subjected to high temperatures to create carbonized fibers. These fibers are then graphitized through additional heat treatment to enhance their mechanical properties further. The resulting carbon fibers are woven into fabrics or laid down as unidirectional sheets.

These fabric or sheet layers are impregnated with a matrix material, often a thermosetting epoxy resin, using techniques like resin transfer molding (RTM) or prepreg layup. The composite is then cured to create the final carbon fiber product. This manufacturing process not only ensures precise control over the arrangement of fibers but also enables customization of mechanical properties based on design specifications.

Applications Across Industries

Carbon fiber’s performance advantages have spurred its integration across various industries:

Aerospace

In the aerospace sector, carbon fiber has revolutionized aircraft design. Its lightweight nature contributes to fuel efficiency, reducing operational costs and environmental impact. Carbon fiber composites are used in components ranging from aircraft frames to interiors, allowing for innovative design approaches that balance structural integrity with weight savings.

Automotive

The automotive industry benefits from carbon fiber’s strength and lightweight properties. Carbon fiber-reinforced polymers are used to construct components like chassis, body panels, and suspension elements. The resultant reduction in weight enhances acceleration, handling, and overall vehicle performance while contributing to improved fuel economy.

Sports and Recreation

Sports equipment manufacturers capitalize on carbon fiber’s strength and flexibility. Tennis rackets, golf clubs, bicycles, and skis incorporate carbon fiber components to enhance player performance through improved energy transfer and reduced vibrations.

Renewable Energy

In the renewable energy sector, carbon fiber finds applications in wind turbine blades. Its high strength ensures the structural integrity of blades subjected to extreme forces, while its lightweight nature enables efficient energy capture and reduces the load on supporting structures.

Medical Devices

Carbon fiber’s biocompatibility and radiolucency make it ideal for medical applications. It is used in devices such as X-ray tables, patient positioning systems, and surgical instruments. Carbon fiber’s strength allows for slim and lightweight designs that are both durable and precise.

Challenges and Future Outlook

While carbon fiber offers numerous performance advantages, its adoption is not without challenges. High production costs, intricate manufacturing processes, and environmental concerns related to precursor materials and energy-intensive production techniques are among the obstacles that need to be addressed.

However, ongoing research and advancements in manufacturing techniques hold promise for overcoming these hurdles. As technology evolves, carbon fiber’s applications are expected to expand further into domains like infrastructure, robotics, and even fashion.

Conclusion

The analysis of carbon fiber products’ performance advantages underscores their transformative impact across industries. From aerospace to sports and renewable energy to medical devices, carbon fiber’s exceptional strength-to-weight ratio, stiffness, corrosion resistance, and fatigue resistance have redefined the possibilities of material engineering. As manufacturing processes continue to evolve, the potential for carbon fiber to revolutionize additional sectors remains boundless. The collaboration between material scientists, engineers, and innovators will undoubtedly drive the continued growth and diversification of carbon fiber applications, shaping the landscape of modern technology and design.

Carbon fiber is a high-performance structural material, which is currently used in the fields of railway transportation, automobile industry, medical equipment and other fields. The editor of the Be-cu prototype in this article mainly introduces the performance advantages of carbon fiber products.

The traditional metal material aluminum alloy will form a dense oxide film during use, which can be used without surface treatment under normal circumstances, not to mention materials with poor corrosion resistance such as steel. Carbon fiber is a non-metallic material that is resistant to chemical media such as acid and alkali, organic solvents, etc. In comparison, carbon fiber products have a longer service life.

The density of carbon fiber materials is very low, about 1.7g/cm3, which is less than 1/4 of steel and 60% of aluminum alloys, so carbon fiber materials have unique advantages in light weight, such as some drone parts, auto parts, etc. Carbon fiber materials can be seen in areas that require weight reduction. While reducing weight, the mechanical properties of carbon fiber materials are also outstanding, and their tensile strength, bending strength and shear strength are better than most structural materials, meeting the needs of use strength.

The theoretical working temperature of carbon fiber materials can reach 2000 °C, but in practical application, carbon fiber is usually fused with matrix materials such as resin to form carbon fiber composite materials, so the working temperature of carbon fiber products cannot reach that standard, generally at 150 °C, The temperature of thermoplastic carbon fiber products is even higher.

China Be-cu Prototype Material Technology Co., Ltd. is a professional manufacturer of carbon fiber products. The company has large-scale hot presses, autoclaves, hydraulic forming tables, CNC high-speed milling machines and other large-scale equipment. And other well-known brands of raw materials production, quality assurance.

ISO 9001 certified. BE-CU Prototype Offering CNC machining carbon fiber and other manufacturing services for carbon fiber marterial. Various capabilities include notching, labeling, drilling carbon fiber, grinding, laser cutting carbon fiber, finishing, plating, marking, CNC milling carbon fiber and turning carbon fiber.We stock high quality 3k carbon fiber sheet in a variety of thickness, types and finish. Its a great material used in applications where light weight and strength are needed such as drones. Unlike other workshops, we have no min order and are often filling orders with a single part. We also don’t make you pay for the full sheet and you only get charged for what is used. With a large selection of material, you should find everything you need to make your project come to life. We are also able to handle larger production runs and provide a competitive pricing. If we don’t have the material or finish you require, we are more the willing to look at bringing it in for you.

What Is Carbon Fiber?Carbon fiber is made of polyacrylonitrile (PAN) (or pitch, viscose) and other organic fibers by carbonization (removal of most elements except carbon) by pyrolysis method under inert gas at high temperature above 1,000 °C. Inorganic polymer fibers with a carbon content of more than 90%.

-

3D Printing Continuous Fibres

-

3D Printing Short Fibre Filled Wires

-

Laser Cutting Carbon Fiber Positioning Keyboard

-

Cnc Turning Industrial Copper-Aluminum Clad Carbon Fiber Machinery Parts

-

Carbon Fiber Luggage Tag Ornaments

-

Laser Cutting Carbon Fiber Guitar Shape Crafts

-

Laser Cutting Carbon Fiber Drone Rack

-

Cnc Milling Carbon Fiber Finger Buckle