Before delving into the differences between chamfers and fillets, let’s establish a clear understanding of what each term represents.In the intricate realm of design and manufacturing, precision stands as a cornerstone that separates excellence from mediocrity. Every curve, edge, and corner of an object has the potential to influence its functionality, aesthetics, and safety. This is where the art of modification comes into play. Among the array of techniques available to designers and engineers, two techniques that hold paramount importance are chamfering and filleting. These methods, often employed to enhance the edges and corners of objects, play a pivotal role in achieving the desired results.

In the world of design, engineering, and manufacturing, precision and attention to detail are paramount. When working with objects that have edges, corners, or intersections, designers and engineers often employ various techniques to enhance functionality, aesthetics, and safety. Two common methods used for modifying edges are chamfering and filleting. In this comprehensive guide, we will explore the key differences between chamfers and fillets, understand their applications, and learn when to use each technique.

View More Articles:

Introduction to Chamfers and Fillets

- Chamfers:A chamfer is a geometric modification applied to the edge of an object, resulting in the creation of a flat, angled surface in place of a sharp corner. This process is achieved by removing material from the corner at a specific angle.

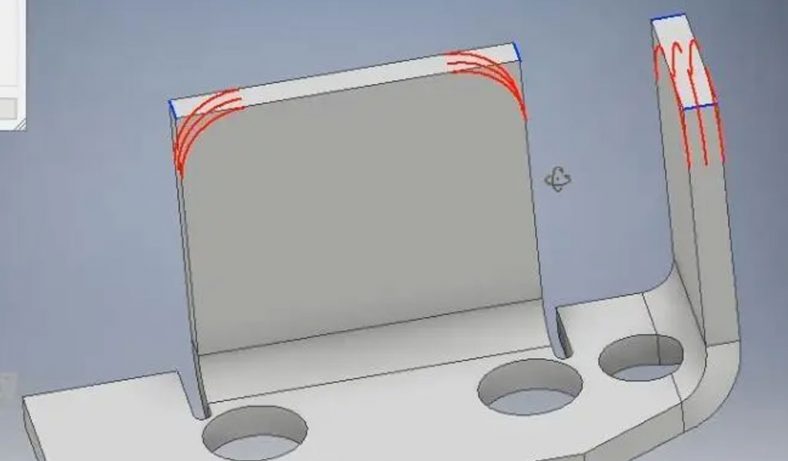

- Fillets:A fillet involves the creation of a curved transition between two intersecting surfaces, replacing a sharp corner or edge with a smooth, rounded surface. Unlike chamfers, fillets add material to the corner rather than removing it.

In this exploration, we embark on a journey into the world of chamfers and fillets, delving into their essence and significance. As we navigate through the intricacies of these techniques, we will unravel their distinctive attributes and the profound impact they have on design and manufacturing processes. By the end of this journey, you will gain a comprehensive understanding of why grasping the differences between chamfers and fillets is not just a matter of technicality but a means to realizing the full potential of any creation.

As we embark on this exploration, keep in mind that these seemingly small details can make a monumental difference in the final product. Let’s dive into the world of chamfers and fillets, where precision meets artistry, and discover how these techniques can transform the way we approach design and engineering.

Chamfers: Exploring the Technique

Defining the Chamfer: Precision in Angles

At the heart of design refinement lies the chamfer—a technique that introduces a subtle yet significant alteration to the edges of an object. A chamfer can be succinctly defined as a flat, angled surface that replaces a sharp corner. This geometric modification holds the power to transform the visual appeal, functional efficiency, and safety of an object, making it an indispensable tool in the designer’s arsenal.

Crafting the Chamfer: Removing Material with Purpose

The process of creating a chamfer involves a meticulous removal of material from the corner at a specific angle. This angle can vary based on the design requirements, and it influences both the aesthetic impact and the functional benefits of the chamfer. The result is a beveled edge that not only serves practical purposes but also contributes to the overall aesthetic harmony of the object.

Purposes of Chamfers: Blending Form and Function

Chamfers find their place in a variety of design contexts, each emphasizing a different facet of their utility.

- Edge Protection and Safety: One of the primary motivations behind using chamfers is to eliminate sharp corners that could pose safety hazards. In applications where human interaction is involved, such as hand-held devices or furniture, chamfers create a user-friendly experience by mitigating the risk of accidental cuts or abrasions.

- Aesthetic Appeal and Modern Design: Chamfers possess the remarkable ability to infuse a touch of modernity into a design. The clean lines and sharp angles they introduce resonate with contemporary aesthetics, allowing designers to craft products that exude sophistication and precision.

- Facilitating Assembly and Disassembly: The chamfer’s contribution to ease of assembly and disassembly cannot be overstated. By removing the sharp edge, chamfers create a lead-in that guides components into alignment, streamlining the overall manufacturing process and reducing the likelihood of errors.

- Enhancing Movement in Machine Parts: In the realm of manufacturing, chamfers play a role in optimizing the functionality of machine parts. By reducing friction at edges, chamfers ensure smoother movement and operation, contributing to the efficiency and longevity of mechanical systems.

In essence, chamfers embody a harmonious fusion of function and aesthetics. They stand as a testament to the intricate balance that designers strive to achieve—a balance that embraces both the practical considerations of safety and assembly and the artistic pursuit of visual refinement.

In the subsequent sections, we will explore the nuances of chamfers’ counterpart—the fillet—and delve deeper into the scenarios where these techniques truly shine. As we proceed, the intricate dance between angles and curves will unfold, showcasing how these seemingly simple modifications can yield profound results in the world of design and engineering.

Fillet: Understanding the Approach

Defining the Fillet: Where Curves Meet Corners

As we venture further into the realm of design refinement, we encounter the fillet—a technique that introduces a touch of curvature to the juncture of intersecting surfaces. A fillet can be aptly described as a smoothly curved transition that replaces the pointed edge, resulting in a gentle, rounded surface. This seemingly simple modification carries profound implications for the functionality, strength, and comfort of an object.

Crafting the Fillet: The Art of Smooth Transitions

The process of creating a fillet involves the artful blending of surfaces, replacing harsh corners with gracefully curving edges. Unlike chamfers that involve material removal, fillets add material to the corner, sculpting it into a seamless curve. This transition serves both practical and aesthetic purposes, giving the object a pleasing tactile quality while also enhancing its structural characteristics.

Primary Purpose of Fillets: Distributing Stress with Grace

While the aesthetic impact of fillets is undeniable, their true power lies in stress distribution. In scenarios where objects are subjected to loads, stress tends to concentrate at sharp corners. Fillets act as stress relievers, distributing the load more evenly across the curved surface. This fundamental attribute is what makes fillets indispensable in applications that demand structural integrity and longevity.

Beyond Stress Distribution: Unveiling Hidden Advantages

Beyond their primary role in stress distribution, fillets bring forth a range of additional benefits that make them invaluable to designers and engineers:

- Improved Flow Dynamics in Fluid Systems: Filleted surfaces are adept at enhancing fluid flow dynamics. By minimizing sharp edges and corners that could cause turbulence, fillets contribute to the efficient movement of liquids or gases through pipes, channels, and conduits.

- Enhanced Ergonomics and Comfortable Handling: Products that are frequently handled, such as tools or consumer electronics, benefit from fillets’ ergonomic attributes. The gentle curves of fillets conform to the natural contours of the human hand, ensuring a comfortable and secure grip.

- Prevention of Stress Concentrations in Manufacturing Processes: Manufacturing techniques like casting and molding can introduce stress concentrations at corners. Fillets strategically applied to these corners disperse stress and minimize the risk of defects, cracks, or deformations during the manufacturing process.

In essence, fillets embody the seamless fusion of aesthetics, engineering, and ergonomics. They demonstrate how a seemingly minor curvature can wield a multitude of benefits that extend far beyond the visual realm. As we delve deeper into the intricacies of these techniques, it becomes evident that design and engineering are not isolated disciplines but interconnected endeavors that harmonize form and function.

In the subsequent sections, we will delve into the distinctions that set chamfers and fillets apart, shedding light on the scenarios where each technique shines most brightly. As we explore these nuances, the importance of discerning between these techniques will become increasingly apparent, revealing a world where precision and creativity interlace to shape our physical surroundings.

Key Differences Between Chamfers and Fillets

As we delve deeper into the world of design modifications, the distinctions that set chamfers and fillets apart become increasingly apparent. Each technique possesses its own unique attributes, offering a range of benefits that cater to different design goals and engineering considerations.

Geometry: The Shape of Transformation

At the core of their dissimilarity lies their fundamental geometry:

- Chamfers: When applied, chamfers result in the creation of flat, angled surfaces. The sharp corner is replaced with a slanted plane, effectively eliminating the pointed edge. This alteration gives objects a streamlined and modern appearance that resonates with contemporary aesthetics.

- Fillets: In contrast, fillets introduce a curvature to the intersection of surfaces. The sharp corner is transformed into a smooth, rounded transition. This curvature not only contributes to visual softness but also ushers in a range of functional advantages.

Stress Distribution: The Balancing Act

One of the key considerations in choosing between chamfers and fillets is their role in stress distribution:

- Fillets: Fillets emerge as champions of stress distribution. The rounded surfaces they introduce ensure that stress is evenly spread across the curvature, minimizing the risk of stress concentrations. This attribute is particularly crucial in load-bearing components, where the even distribution of stress is pivotal for structural integrity.

- Chamfers: While chamfers offer numerous benefits, their ability to distribute stress is not as potent as that of fillets. In scenarios where stress distribution is a primary concern, fillets may be the preferred choice due to their inherent ability to evenly disperse forces.

Aesthetics: Where Lines and Curves Converge

The aesthetic impact of chamfers and fillets is profound, often influencing design decisions:

- Chamfers: Chamfers contribute to a design’s visual appeal through their sharp, angular lines. They evoke a sense of precision and modernity that suits products aiming for a contemporary or cutting-edge look.

- Fillets: Fillets offer a contrasting aesthetic by introducing soft curves that provide a more organic and approachable appearance. This aesthetic quality makes them particularly suitable for designs that prioritize comfort and tactile interaction.

Assembly and Disassembly: Aiding in Connection

Both chamfers and fillets play roles in the ease of assembly and disassembly:

- Chamfers: Chamfers create lead-ins that aid in aligning and connecting parts during assembly. The absence of sharp corners reduces the likelihood of misalignment and simplifies the overall assembly process.

- Fillets: While fillets are not primarily designed for this purpose, their smooth transitions can also prevent snags and catch points during assembly or disassembly. The rounded edges of fillets contribute to a seamless joining process.

Impact on Measurements: Dimensional Considerations

The implementation of chamfers and fillets can impact the object’s dimensions:

- Chamfers: Chamfers involve material removal, altering the dimensions of the object by creating a beveled edge. Designers must factor in this dimension change when planning and executing designs.

- Fillets: Fillets, in contrast, maintain the original dimensions of the object at the intersection. This attribute is advantageous when precise measurements are paramount and need to be preserved.

In the subsequent sections, we will explore the practical applications of chamfers and fillets, illuminating the scenarios where these techniques are most aptly employed. By comprehending the nuances of these techniques, designers and engineers can make informed decisions that align with the specific goals of their projects. Through this understanding, the fusion of creativity and engineering precision takes on a new dimension, ushering in a world of possibilities where design becomes an art that marries form and function.

When to Use Chamfer and Fillet

Knowing when to use chamfers and fillets in your design and engineering projects is essential for achieving the desired outcomes. Both techniques serve different purposes and offer specific advantages based on the context of your project. Let’s explore when to use chamfers and fillets:

When to Use Chamfers

- Edge Protection and Safety: Chamfers are ideal when safety is a concern. Use chamfers in products that will be frequently handled to eliminate sharp edges and reduce the risk of cuts or abrasions. This is particularly important in objects intended for consumer use.

- Aesthetic Enhancement: If your design aims for a modern and precise aesthetic, chamfers can provide the desired look. The sharp lines and angles created by chamfers resonate with contemporary design trends.

- Assembly and Disassembly: Chamfers are valuable when your product requires multiple cycles of assembly and disassembly. The lead-ins created by chamfers make alignment and connection of components easier, saving time during manufacturing and maintenance.

- Machine Components: When designing machine parts, chamfers can help reduce friction at edges. By creating smooth transitions, chamfers optimize movement and operation, contributing to the overall efficiency of mechanical systems.

When to Use Fillets

- Stress Distribution: Fillets are essential in load-bearing components or structures that will experience forces. When even stress distribution is crucial to prevent stress concentrations, fillets help ensure the structural integrity and longevity of the object.

- Enhanced Flow Dynamics: If your project involves fluid systems, fillets play a vital role. Use fillets to reduce turbulence caused by sharp corners, promoting smooth flow of liquids or gases through pipes and channels.

- Ergonomics: Fillets are ideal for products that will be handled frequently. The rounded edges provided by fillets offer ergonomic benefits by conforming to the natural contours of the human hand, enhancing user comfort and grip.

- Manufacturing Applications: In manufacturing processes like casting or molding, fillets prevent stress-related issues. By evenly distributing stress, filleted corners reduce the risk of defects, cracks, or deformations during the manufacturing process.

Choosing Between Chamfers and Fillets

When deciding whether to use chamfers or fillets, consider the following factors:

- Functional Requirements: Determine the primary purpose of your design. Is stress distribution critical? Are you aiming for a specific aesthetic? Do you need to optimize assembly?

- Aesthetics: Consider the visual appeal you want to achieve. Chamfers offer a modern and precise look, while fillets provide softer and more ergonomic curves.

- Safety: If your design will be handled by users, prioritize safety by using chamfers to eliminate sharp edges.

- Stress Distribution: For load-bearing components, choose fillets to evenly distribute stress and enhance structural integrity.

- Fluid Dynamics: If your design involves fluid systems, fillets can improve flow dynamics and reduce turbulence.

- User Comfort: If ergonomics and user comfort are important, opt for fillets to provide a comfortable grip.

- Manufacturing Processes: In manufacturing, consider using fillets to prevent stress-related issues during production.

In essence, the choice between chamfers and fillets depends on the specific goals of your project, ranging from aesthetics to functionality, safety, and manufacturing considerations. By understanding the distinct advantages of each technique, you can make informed design decisions that result in products that are both visually appealing and functionally effective.

Applications of Chamfers and Fillets

As we delve into the practical realm of design and engineering, the real-world applications of chamfers and fillets come to the forefront. These techniques, each possessing their unique attributes, find their niches in various scenarios where they excel in enhancing functionality, safety, aesthetics, and overall design quality.

Chamfers: Enhancing Form and Function

- Edge Protection: Safeguarding Users:One of the most fundamental applications of chamfers lies in edge protection and safety. By eliminating sharp edges, chamfers prevent the risk of cuts, abrasions, and potential harm to users. Products that come into frequent contact with human skin, such as handheld devices or furniture, benefit immensely from chamfers that render edges more user-friendly and secure.

- Aesthetic Enhancement: Modernizing Design:Chamfers also play a pivotal role in enhancing the visual appeal of objects. With their clean lines and precise angles, chamfers contribute to a sense of modernity and sophistication. They are a particularly fitting choice for products that aim to communicate precision, technology, and innovation through their design.

- Assembly Facilitation: Streamlining Production:Efficiency in assembly and disassembly is a hallmark of well-designed products. Chamfers offer an advantage in this realm by facilitating the alignment and connection of parts. The lead-ins created by chamfers guide components into position, minimizing the risk of errors during assembly and ensuring a smoother, more efficient manufacturing process.

- Machine Components: Reducing Friction:In the domain of machine components, chamfers prove their mettle by reducing friction. By eliminating sharp edges and corners that could cause unnecessary resistance, chamfers optimize movement and operation. The reduction in friction contributes to the efficiency, reliability, and longevity of mechanical systems.

Fillets: Engineering for Excellence

- Stress Distribution: Bolstering Structural Integrity:Fillets stand as exemplars of stress distribution. In load-bearing components subject to forces, fillets play a pivotal role in distributing stress evenly across the curvature. This even distribution mitigates the risk of stress concentrations that could lead to premature failure or structural compromise.

- Enhanced Flow Dynamics: Optimizing Fluid Movement:In the realm of fluid dynamics, fillets are catalysts for improved flow. By minimizing turbulence caused by sharp edges and corners, fillets contribute to the smooth movement of liquids and gases. This advantage is particularly relevant in applications involving pipes, channels, and conduits, where efficient flow is paramount.

- Ergonomics: Designing for Comfort:The ergonomic benefits of fillets are far-reaching. The gentle curves introduced by fillets conform to the natural contours of the human body, providing a comfortable and secure grip. Products that are frequently handled, such as tools or consumer electronics, benefit from the ergonomic advantages offered by filleted edges.

- Die-Casting Applications: Mitigating Manufacturing Stresses:Fillets also find their place in manufacturing processes, particularly in techniques like die-casting. During cooling, stress concentrations at corners can result in cracking or deformation. Filleted corners alleviate this concern by evenly distributing stress, enhancing the integrity and quality of manufactured components.

In the final section of this exploration, we will draw upon the insights gained from the differences and applications of chamfers and fillets to offer a comprehensive conclusion. The interplay between these techniques, guided by design intent and engineering acumen, highlights the intricate dance of creativity and precision that defines the world of design and manufacturing.

Conclusion

In the intricate tapestry of design and engineering, the techniques of chamfering and filleting stand as guiding stars, illuminating the path to excellence. As we conclude our journey through the nuances of these methods, it becomes evident that their impact extends far beyond the surface level. The choices between chamfers and fillets, driven by design intent and engineering acumen, yield outcomes that transcend aesthetics, encompass functionality, and underscore the importance of precision.

Geometry, Stress Distribution, Aesthetics, Assembly, and Measurements: Unveiling the Distinctions

The differences between chamfers and fillets can be distilled into five key aspects:

- Geometry: Chamfers create flat, angled surfaces, while fillets introduce gentle curves.

- Stress Distribution: Fillets excel in distributing stress evenly, crucial for structural integrity.

- Aesthetics: Chamfers exude sharp angles for modernity, while fillets offer soft curves for comfort.

- Assembly and Disassembly: Chamfers aid in alignment, while fillets prevent snags during assembly.

- Impact on Measurements: Chamfers alter dimensions, whereas fillets maintain them.

These distinctions, when considered in harmony, empower designers and engineers to make informed decisions that align with the intended purpose of their creations.

Choosing the Right Technique: A Design Imperative

In a world of infinite possibilities, the ability to discern between chamfers and fillets takes on a significance of its own. Each technique possesses its unique strengths, enabling designers to address diverse design goals and engineering challenges. The careful selection of chamfers or fillets, driven by a deep understanding of their attributes, ensures that the final product not only functions optimally but also exudes the desired aesthetic and tactile qualities.

Empowerment through Understanding: Designing Excellence

Above all, this exploration highlights how a comprehensive understanding of chamfers and fillets empowers designers and engineers to craft products that transcend mediocrity. The ability to navigate between sharp lines and gentle curves, between modernity and comfort, becomes a testament to the intricacies of the design process. By mastering the interplay of these techniques, designers stand poised to create objects that not only meet functional requirements but also resonate with beauty and artistry.

In conclusion, the difference between chamfers and fillets is not merely a matter of technicality—it’s a journey that embodies the fusion of engineering precision and creative brilliance. As we step away from this exploration, let us carry with us the understanding that these seemingly small decisions can make monumental differences, enriching the world with objects that are functional, aesthetically pleasing, and structurally sound.