China and usa cnc spun shops have transformed the global market with exceptional CNC spinning capabilities. China,Uk and usa is currently at the forefront of world manufacturing output, with over $2 trillion in production. Are you seeking the quality and cost CNC metal spinning company? Then look no further.

Explore this compilation of 10 CNC spinning companies online that excel in delivering top-class products. These companies boast well-equipped facilities, employ the best cnc spun methods, and have experienced engineers. Without further ado, let’s get to it.

Brief Overview of the Global CNC Metal Spinning Market size In 2024

CNC metal spinning is a specialized manufacturing process that involves shaping metal disks or tubes into desired forms using computer-controlled machinery. This process is particularly valued for its ability to produce complex shapes with high precision and consistency. The market scope includes various types of CNC metal spinning machines, software, and services utilized across multiple industries, such as aerospace, automotive, healthcare, and defense.

The global Computer Numerical Control (CNC) metal spinning market has seen steady growth over the past few years, driven by advancements in manufacturing technology, increasing demand across various sectors, and the need for high-precision metal components. As of 2024, this market is anticipated to continue its expansion, reflecting broader trends in industrial automation and advanced manufacturing techniques.

Market Size and Growth Factors

The global CNC metal spinning market size in 2024 is projected to reach approximately USD 1.8 billion. This growth is driven by several key factors:

- Technological Advancements: Continuous improvements in CNC technology, including enhanced software, better tooling materials, and more efficient machine designs, are driving market growth. These advancements enable higher productivity, better quality control, and the ability to manufacture more complex components.

- Demand from Key Industries: Major industries such as aerospace, automotive, and healthcare continue to drive demand for CNC metal spinning. The need for lightweight, durable, and high-precision components in these sectors is critical, and CNC metal spinning offers a viable solution.

- Customization and Efficiency: The increasing demand for customized metal components with specific properties and shapes is boosting the adoption of CNC metal spinning. The process’s efficiency, combined with its ability to produce small and large batches economically, makes it an attractive option for manufacturers.

- Economic and Industrial Growth: Emerging economies, particularly in the Asia-Pacific region, are experiencing rapid industrialization and infrastructure development. This growth is creating new opportunities for the CNC metal spinning market as manufacturers invest in advanced production capabilities.

- Sustainability Trends: The emphasis on sustainable manufacturing practices is leading to the adoption of CNC metal spinning, which can reduce material waste and energy consumption compared to traditional methods.

Regional Market Analysis

- North America: The North American market, led by the United States and Canada, remains significant due to the presence of major aerospace and automotive manufacturers. The region’s focus on technological innovation and advanced manufacturing techniques supports market growth.

- Europe: Europe continues to be a strong market, with countries like Germany, the UK, and France at the forefront. The region’s emphasis on high-quality manufacturing and precision engineering is a major growth driver.

- Asia-Pacific: This region is expected to see the highest growth rate, driven by the expansion of the automotive and aerospace industries in China, Japan, and India. Rapid industrialization and infrastructure development further bolster market demand.

- Latin America: Steady growth is anticipated in Latin America, with Brazil and Mexico being key contributors. The expansion of the automotive and energy sectors in these countries supports market development.

- Middle East and Africa: Gradual adoption of CNC metal spinning technology in the Middle East and Africa is driven by the growth of the aerospace and defense industries. Economic diversification and industrial development initiatives are expected to enhance market growth.

How to Choose the Right Online CNC Metal Spinning Companies

Selecting the right metal spinning company online can be a crucial decision for your business. The right partner can ensure high-quality products, timely delivery, and overall efficiency in your production process. Here are several key factors to consider when choosing a metal spinning company online:

1. Evaluate Their Experience and Expertise

- Experience in the Industry: Look for companies with a significant amount of experience in metal spinning. Experienced companies are more likely to understand the complexities of the process and have refined their techniques over time.

- Industry Expertise: Ensure the company has experience in your specific industry. For instance, if you need components for the aerospace industry, a company with a track record in producing high-precision aerospace parts would be ideal.

- Technical Expertise: Assess the technical capabilities of the company. This includes the types of materials they can handle (aluminum, stainless steel, titanium, etc.), the range of sizes they can spin, and their ability to produce complex shapes.

2. Check Certifications and Standards

- ISO Certifications: ISO certifications (e.g., ISO 9001 for quality management systems) are indicators of a company’s commitment to maintaining high standards.

- Industry-Specific Certifications: Depending on your industry, certain certifications may be critical. For example, AS9100 is a widely adopted quality management system for the aerospace industry.

- Compliance with Standards: Ensure the company complies with industry standards and regulations relevant to your products.

3. Assess Quality and Precision

- Quality Control Processes: Investigate the company’s quality control processes. How do they ensure that each part meets the required specifications?

- Inspection Capabilities: Check if the company has advanced inspection capabilities, such as coordinate measuring machines (CMM) and other precision measurement tools.

- Past Projects and Case Studies: Reviewing case studies or past projects can provide insight into the quality and precision of their work.

4. Review Technology and Equipment

- Modern Equipment: Ensure the company uses state-of-the-art CNC metal spinning machines and other advanced equipment. Modern technology can enhance precision, efficiency, and production capabilities.

- Maintenance and Upgrades: Inquire about how often the company upgrades and maintains its equipment. Well-maintained equipment is crucial for consistent quality.

- Software Utilization: Check if they use advanced software for design and simulation, such as CAD/CAM tools. These can optimize the manufacturing process and improve the accuracy of the final product.

5. Consider Capacity and Scalability

- Production Capacity: Ensure the company can handle your current production volume. Ask about their maximum production capacity and lead times.

- Scalability: If your business is growing, you may need a partner who can scale their operations to meet increasing demand.

- Flexibility: Evaluate the company’s flexibility in handling different batch sizes and custom orders.

6. Evaluate Customer Service and Support

- Responsiveness: The company should be responsive to inquiries and provide clear communication. Quick responses to questions and concerns are essential.

- Technical Support: Assess the level of technical support available. Can they provide assistance with design modifications or technical challenges?

- Long-Term Partnership: Look for a company that is interested in building a long-term partnership rather than just a one-time transaction.

7. Check References and Reviews

- Client References: Ask for references from past or current clients. Speaking directly with other customers can provide valuable insights into the company’s reliability and performance.

- Online Reviews: Look for reviews on industry-specific forums, social media, and review websites. Pay attention to both positive and negative feedback to get a balanced view.

- Case Studies: Review case studies on the company’s website. These often highlight their capabilities and success stories in detail.

8. Consider Cost and Value

- Transparent Pricing: Ensure the company provides transparent pricing with no hidden costs. Get detailed quotes and compare them with other companies.

- Value for Money: Don’t just go for the lowest price. Consider the value you are getting for your money in terms of quality, service, and reliability.

- Payment Terms: Discuss payment terms and conditions upfront to avoid any misunderstandings later.

9. Review Delivery and Logistics

- Timely Delivery: Assess the company’s track record for on-time delivery. Delays can disrupt your production schedule and affect your business.

- Logistics Capabilities: Check their logistics capabilities and how they handle shipping and delivery. Efficient logistics are crucial for maintaining the supply chain.

- Global Reach: If you require international shipping, ensure the company has experience with global logistics and understands the complexities involved.

10. Sustainability Practices

- Environmental Policies: Check if the company has environmental policies in place. Sustainable practices are becoming increasingly important in the industry.

- Waste Management: Inquire about their waste management practices. Efficient waste management can indicate a commitment to sustainability.

- Energy Efficiency: Look for companies that use energy-efficient processes and machinery. This not only reduces environmental impact but can also lead to cost savings.

Top 10 Online CNC Metal Spinning Companies in Global(China,USA And UK)

| No. | Company Name | City | Year Founded | Employee Size |

|---|---|---|---|---|

| 1 | Zhongshan BE-CU Spinning Company | Zhongshan | 2007 | 200 |

| 2 | lewark metal spinning inc | Ohio | 1993 | 100 |

| 3 | g & g metal spinners inc | Indianapolis | 1960 | 100 |

| 4 | acme spinning company | Minneapolis | 1908 | 200 |

| 5 | american metal spinning products inc | Long Island | 1986 | 200 |

| 6 | bracone metal spinning inc | Southington | 2000 | 20 |

| 7 | calder metal spinning company | Brighouse | 1947 | 200 |

| 8 | calibre metal spinning ltd | Waterlooville | 2010 | 100 |

| 9 | century metal spinning company | Bensenville | 2002 | 100 |

| 10 | craft metal spinning ltd | New York | 1964 | 200 |

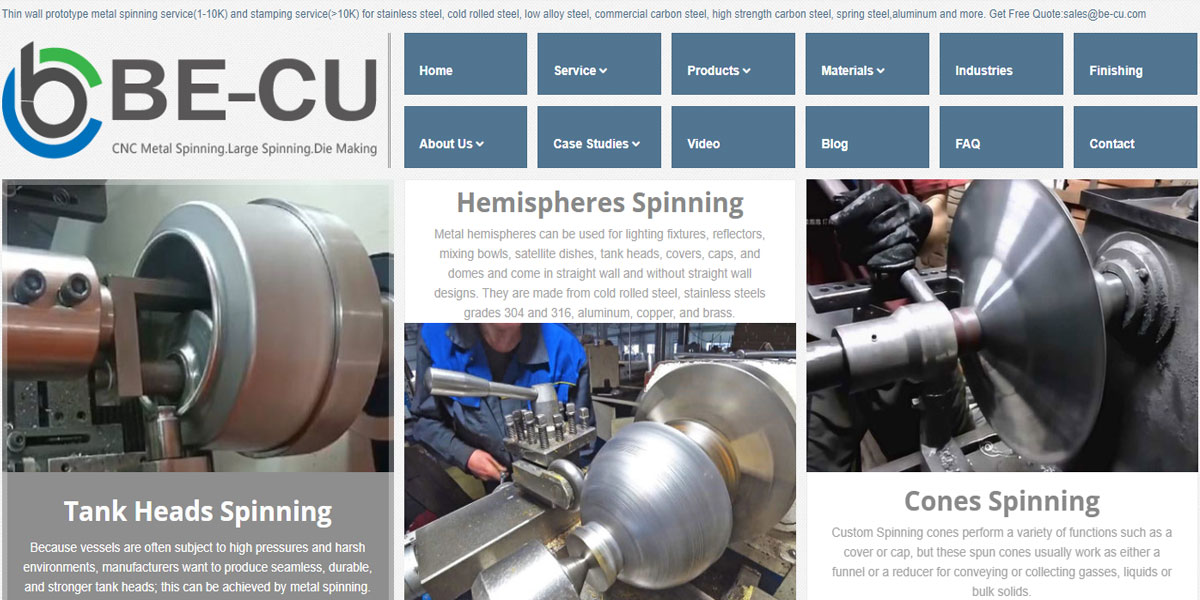

1. Zhongshan BE-CU Spinning Company

Founded in 2007, BE-CU Spinning’s headquarters is located in Zhongshan , China which grew and developed until we expanded into our second location in 2012 in jiangmen, china. Since then, both of BE-CU Spinning’s locations have continued to expand while increasing our capabilities and techniques. Prototypes and low to high run production volumes are offered.Capable of spinning parts with up to 120 in. diameter, +/- 0.0031 to 0.094 in. tolerance for commercial applications, and +/- 0.001 to 0.045 in. tolerance for special applications.

- Today, we employ 200 people and are growing still.

- We schedule approximately 80 primary machines – 40 spun machines – to produce across 3 shifts.

- Every month, we produce and ship over 1.1 million precision spun components to diverse industries.

- Go Website: metal-spun.com

2.lewark metal spinning inc

LMS is a privately owned company in Dayton, Ohio. We service a broad range of industries from cookware to aerospace. Since the company began in 1993, LMS has become a nationally respected and sought after metal spinning company. We earned our excellent reputation by focusing on the customer first. We believe you will receive the best customer service and reliable quality here.

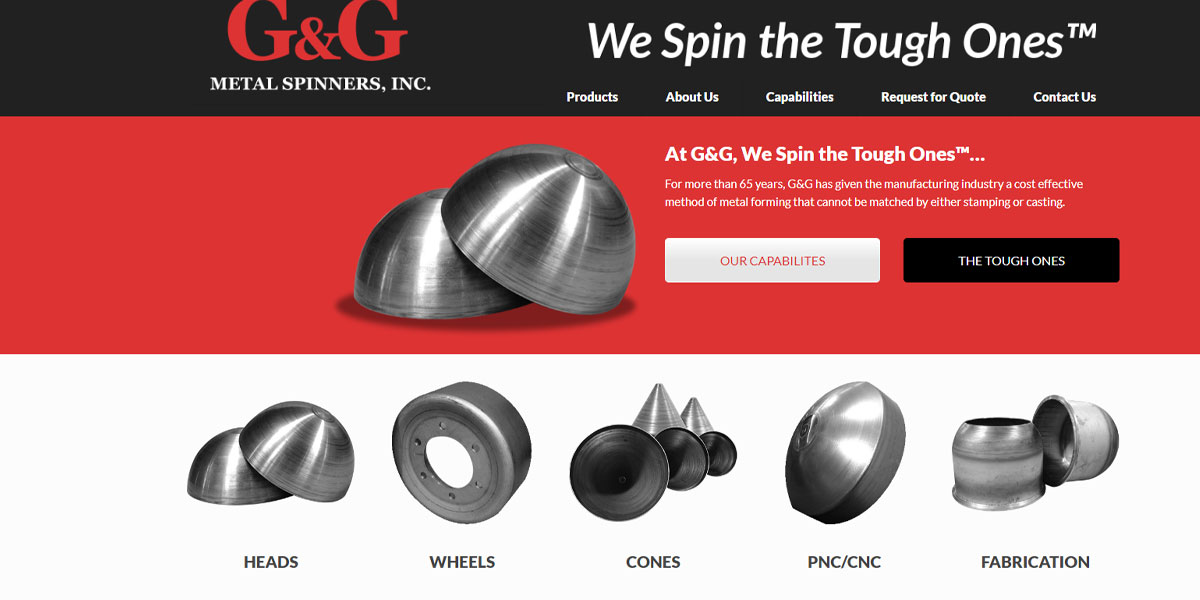

3.g & g metal spinners inc

G&G uses state-of-the art CNC and PNC machines to meet the large quantity production orders that require the same part each time. G&G offers all of the capabilities of a spinning manufacturer, plus those associated with fabrication and prototype facilities.

We can work with a customers in development of tooling and product, or take prints straight into production. From prototype to production, G&G is committed to the highest level of quality, consistent workmanship, and competitive pricing. At G&G, We spin the tough ones™

4.acme spinning company

Since 1908, Acme Metal Spinning has grown into one of the largest metal spinning manufacturers in the Midwest. For over a century, Acme has built an industry-wide reputation for high quality metal spinnings in a broad range of materials in diameters from 0.25 inch up to 120 inches.

Acme Metal Spinning is a reliable and trusted just-in-time supplier having pioneered many new metal spinning fabrication techniques and processes for the benefit of its many long-time and satisfied customers. The company provides quality metal spinnings to leading lighting, architectural metal, off-highway vehicle, aerospace, medical, military, chemical, agricultural and many other industries.

The company has complete in-house CNC metal spinning equipment including dozens of spinning machines and systems, conventional spinning equipment, trimming, cutoff and beading equipment as well as many value-added services are available such as hole punching, flanging and finishing.

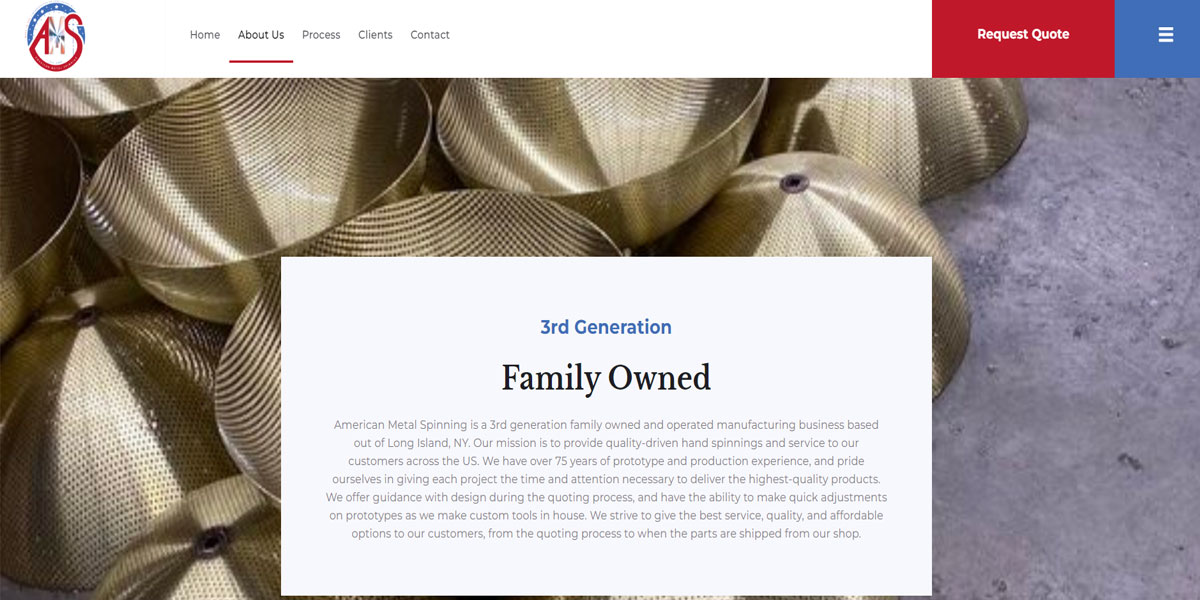

5.american metal spinning products inc

American Metal Spinning is a 3rd generation family owned and operated manufacturing business based out of Long Island, NY. Our mission is to provide quality-driven hand spinnings and service to our customers across the US. We have over 75 years of prototype and production experience, and pride ourselves in giving each project the time and attention necessary to deliver the highest-quality products. We offer guidance with design during the quoting process, and have the ability to make quick adjustments on prototypes as we make custom tools in house. We strive to give the best service, quality, and affordable options to our customers, from the quoting process to when the parts are shipped from our shop.

6.bracone metal spinning inc

BMS Aerospace Is A Diverse And Progressive Manufacturer Of Precision Formed Metal Components For Military And Commercial Applications Specializing In The Repair And Manufacture Of A Wide Variety Of Aviation Engine And Airframe Components. What Started As A One Man Shop In A Garage Now Employs 20 People And Is Located In A 20,000 Square Foot Facility. Through Paul Bracone’s Continued Dedication And Hard Work Bracone Has Seen Continued Growth For Over 25 Years. BMS Has A Proud History Of Accomplishments Including Various Certifications And Long Term Contracts With The Leaders In The Industry. Our Customer List Includes The World’s Premier Gas Turbine And APU Manufacturers, Specializing In A Broad Range Of Complex Engine Components.

We Are Committed To Continuous Improvement In Quality And Productivity To Satisfy Our Customers Needs. Our Goal Is To Become A Total Quality Company By Continuously Improving All Our Work Processes To Satisfy Or Exceed The Requirements Of Our Customers. At BMS It Has Always Been A Priority To Strive To Provide Our Customer With Close Cooperation, Excellent Workmanship, Effective Quality Procedures, Competitive Pricing And On-Time Delivery. Here At BMS We Intend To Continue To Do Just That For Many Years To Come.

7. calder metal spinning company

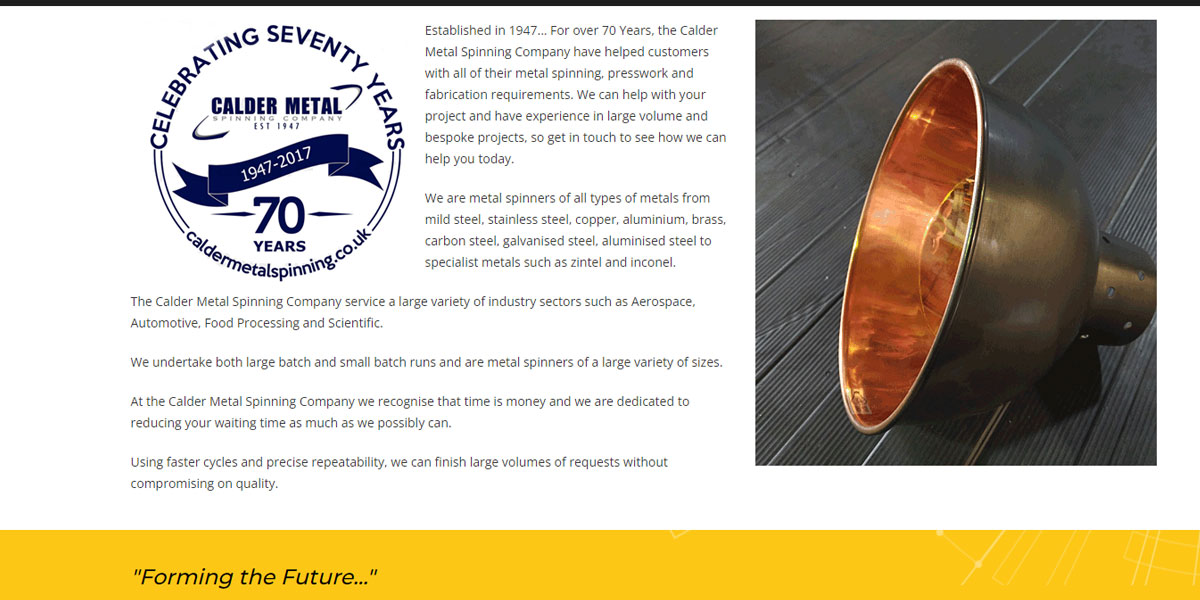

Established in 1947… For over 70 Years, the Calder Metal Spinning Company have helped customers with all of their metal spinning, presswork and fabrication requirements. We can help with your project and have experience in large volume and bespoke projects, so get in touch to see how we can help you today.

We are metal spinners of all types of metals from mild steel, stainless steel, copper, aluminium, brass, carbon steel, galvanised steel, aluminised steel to specialist metals such as zintel and inconel.

The Calder Metal Spinning Company service a large variety of industry sectors such as Aerospace, Automotive, Food Processing and Scientific.

We undertake both large batch and small batch runs and are metal spinners of a large variety of sizes.

At the Calder Metal Spinning Company we recognise that time is money and we are dedicated to reducing your waiting time as much as we possibly can.

Using faster cycles and precise repeatability, we can finish large volumes of requests without compromising on quality.

8.calibre metal spinning ltd

Calibre metal spinning was founded in 2010 by brothers David & Kevin Hobbs. Based in Waterlooville (Near Portsmouth) Hampshire

Our customers come from all across the UK and Europe, and they value our friendly yet professional approach. Our team of six spinners and welders have over sixty years combined experience so we’re confident we have the experience and expertise to turn our customers’ requirements into perfect products, no matter what the challenge.

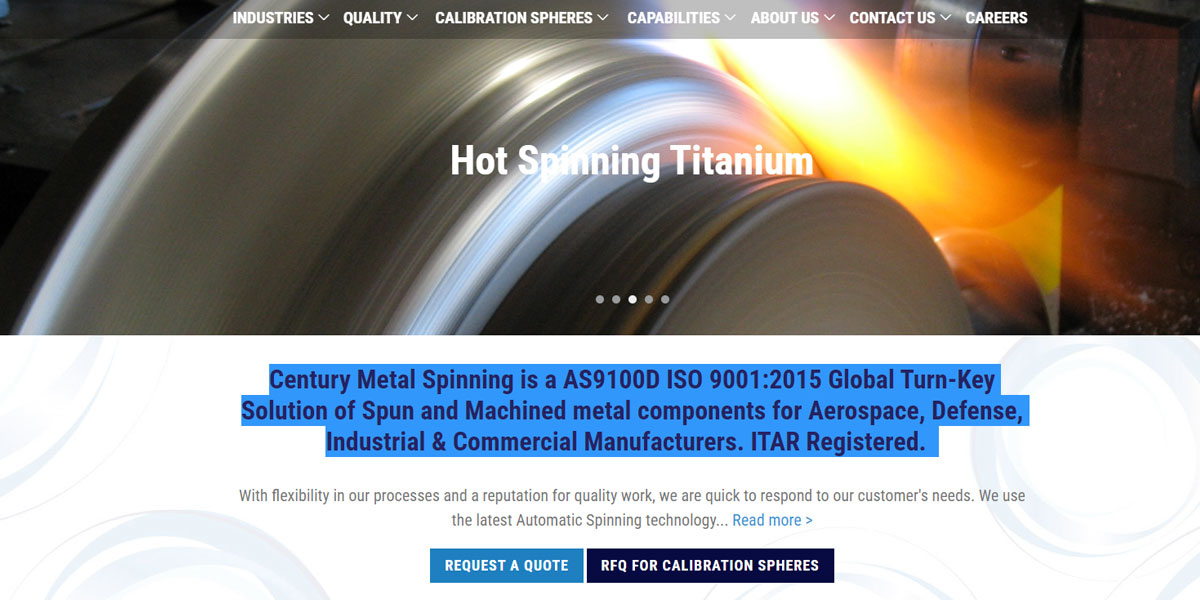

9.century metal spinning company

Century Metal Spinning is a AS9100D ISO 9001:2015 Global Turn-Key Solution of Spun and Machined metal components for Aerospace, Defense, Industrial & Commercial Manufacturers. ITAR Registered.

10.craft metal spinning ltd

Established in 1964 and incorporated in 1969, Metal Craft Spinning and Stamping is now operated by fourth-generation family members. Our commitment to quality, on-time delivery, and personalized customer service has resulted in our customers coming back to us for their manufacturing needs time and again.

Whether you require laser cutting, metal spinning, or stamping, we’ve got you covered. Equipped with decades of industry experience and state-of-the-art fabrication equipment, we have the knowledge and skills to deliver precise and accurate metal components that fully meet your needs.

Outsource Custom CNC Metal Spinning Parts from BE-CU.COM

Are you in search of a trustworthy CNC Metal Spinning company in China? We understand the challenges in finding the right partner with optimal solutions. That is why we have provided the best China-based specialist in CNC Metal Spinning services. When selecting a CNC Metal Spinning manufacturer, crucial considerations include machine quality and reliability, production capacity with lead time, cost-effectiveness, customization and flexibility, and technical support.

Considering all these factors, BE-CU stands out for our advanced CNC Metal Spinning services. As an ISO-certified prototype company, Be-cu is well-equipped with advanced CNC Metal Spinning machines and parts inspection facilities. They provide comprehensive CNC Spun services, covering cnc spinning, Electrical Discharge Machining, and various surface finishes. With over 30 years of experience, cutting-edge technology, and a skilled engineering team, BE-CU is a productive and results-driven CNC Metal Spinning service provider committed to ensuring your satisfaction.

Submit your design file for an instant CNC Metal Spinning quote. We look forward to collaborating with you!