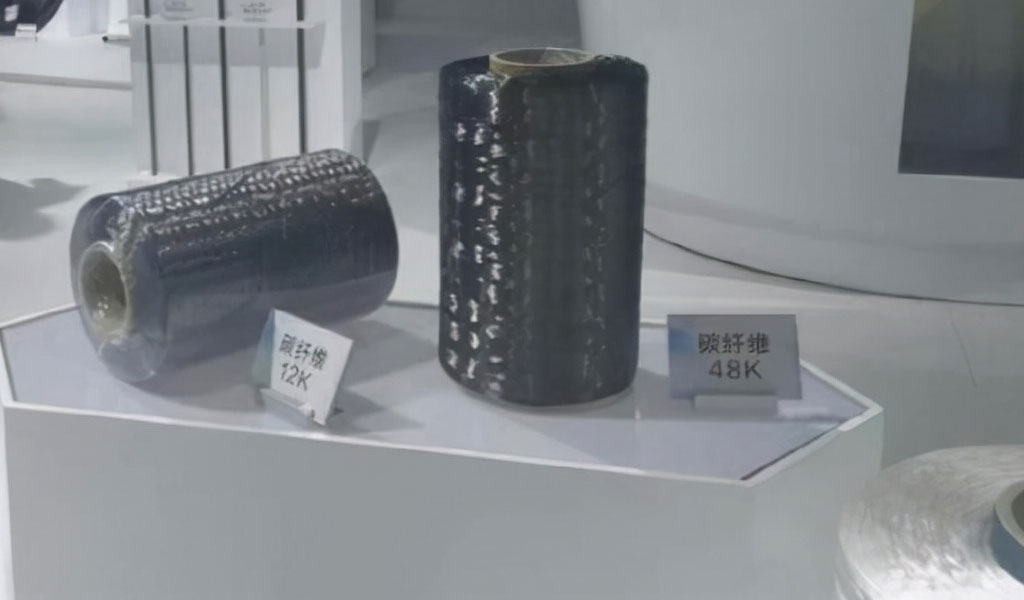

Pre-oxidize and carbonize fibers with high carbon content at a high temperature of thousands of degrees Celsius to obtain a material with a carbon content higher than 92%, which is carbon fiber. Long carbon filaments are generally woven into cloth. Carbon fiber board is made of carbon cloth pre-impregnated with resin and pressed, which can be used for building reinforcement and micro manufacturing into mechanical parts or daily necessities.carbon fiber board,How strong is it?

Let’s first explain what the word strength means. Under the action of external force, the function of materials will gradually deteriorate. The reason why they can be used as usual is because they have a certain resistance to damage.

The strength of materials such as paper, cotton, and ceramics is lower, while the strength of steel, titanium alloy, and stone is higher. The strength of carbon fiber board is very high, and the tensile strength of ordinary T300, 3k carbon fiber board can reach 3600MPa. Some of its other properties, such as high temperature resistance, corrosion resistance, stability, waterproof ability, etc. are very good.

Basic properties of carbon fiber sheets

Carbon fiber sheet is a composite material with excellent mechanical properties, composed of high modulus carbon fiber and binder. Compared with traditional materials, carbon fiber sheets have the advantages of high strength, high modulus, low density, and corrosion resistance. Its strength performance in different directions will be introduced below.

Tensile Strength

The tensile strength of carbon fiber sheets is mainly determined by the strength of carbon fiber bundles and the bonding strength between bundles. When the fiber and load directions are the same, the tensile strength of carbon fiber sheets can be close to the strength of unidirectional fiber reinforced materials, reaching a level higher than 1000MPa. Moreover, at the same strength level, the density of carbon fiber sheets is much lower than that of metal materials.

Compression Strength

Since the fiber content of carbon fiber sheets is as high as more than 60%, its transverse strength is relatively low and is much weaker in the compression direction than in the fiber direction. In order to improve its compressive strength, multi-axial weaving, fiber interlacing, lamination, etc. are usually used to enhance its compressive strength.

Bending Strength

The bending strength of carbon fiber sheets depends on their internal structure and fiber orientation. Normally, under fiber control, its bending strength is much higher than that of metal materials.

Factors Affecting Intensity

In addition to the performance advantages of the material itself, the strength of carbon fiber sheets is also affected by many factors. The most important factors are the supplier’s production process, material density, resin impregnation amount, fiber volume fraction, fiber orientation, etc. At the same time, the selection and combination of reinforcement methods are also important factors affecting intensity. After continuous optimization, various enhancement methods can currently provide strength levels higher than 1500MPa.

Comparing carbon fiber boards and engineering plastic boards of the same thickness, their density is about the same, about 1.78 g/cm3, and the volume is similar, but in terms of strength, the strength of engineering plastic boards is at most close to ordinary steel, while the strength of carbon fiber boards is that of steel. several times as much.

After reading the above content, I believe you have a certain understanding of the strength of the carbon fiber board. China Be-cu Rapid Prototype Material Technology Co., Ltd. can produce carbon fiber boards with different strengths and specifications. If you have any needs, please click the online customer service consultation on the page. We have the most advanced equipment, and we can make processed parts and products according to customer’s requirements, and the quality reaches international standards.

ISO 9001 certified. BE-CU Prototype Offering CNC machining carbon fiber and other manufacturing services for carbon fiber marterial. Various capabilities include notching, labeling, drilling carbon fiber, grinding, laser cutting carbon fiber, finishing, plating, marking, CNC milling carbon fiber and turning carbon fiber.We stock high quality 3k carbon fiber sheet in a variety of thickness, types and finish. Its a great material used in applications where light weight and strength are needed such as drones. Unlike other workshops, we have no min order and are often filling orders with a single part. We also don’t make you pay for the full sheet and you only get charged for what is used. With a large selection of material, you should find everything you need to make your project come to life. We are also able to handle larger production runs and provide a competitive pricing. If we don’t have the material or finish you require, we are more the willing to look at bringing it in for you.

What Is Carbon Fiber?Carbon fiber is made of polyacrylonitrile (PAN) (or pitch, viscose) and other organic fibers by carbonization (removal of most elements except carbon) by pyrolysis method under inert gas at high temperature above 1,000 °C. Inorganic polymer fibers with a carbon content of more than 90%.

-

3D Printing Continuous Fibres

-

3D Printing Short Fibre Filled Wires

-

Laser Cutting Carbon Fiber Positioning Keyboard

-

Cnc Turning Industrial Copper-Aluminum Clad Carbon Fiber Machinery Parts

-

Carbon Fiber Luggage Tag Ornaments

-

Laser Cutting Carbon Fiber Guitar Shape Crafts

-

Laser Cutting Carbon Fiber Drone Rack

-

Cnc Milling Carbon Fiber Finger Buckle