In recent years, the domestic industrial production capacity has become more and more advanced, and more and more new materials have entered people’s lives. It is also very popular, and the demand for products of this material is increasing.

The Method Of Choose A Zirconia Ceramic Machining Factory

When purchasing zirconia ceramic workpieces, it is necessary to choose a reliable machining manufacturer. Be-Cu Ceramics specializes in the production of various zirconia ceramics and various workpieces. I will introduce to you in detail what should be paid attention to when choosing a zirconia ceramic machining manufacturer.

When choosing a zirconia ceramic machining manufacturer, don’t be too hasty. You need to understand the market first. Although there are many machining manufacturers on the market, not all manufacturers meet the requirements for their popularity and reputation.

Manufacturers with high reputation and good reputation can be known by just inquiring a little. Generally speaking, manufacturers with better reputation are more reliable. If there is a need for zirconia ceramic machining, you may wish to spend more time and energy to understand the basic situation of the machining manufacturers who intend to cooperate with them, and find out whether they are regular manufacturers, and it is best to send a special person to conduct an on-site inspection.

On-the-spot inspection is a necessary way to choose a zirconia machining plant. Whether the machining plant is worthy of cooperation can quickly make a decision from the advanced nature of its production equipment and whether the maturity of the production process meets the requirements.

In addition, if there is an opportunity to understand its current business volume, if there are a lot of orders received every day, many customers are willing to cooperate with it, and the zirconia ceramic products produced for other customers, regardless of the quality It is still very good in performance, and such a machining manufacturer can definitely cooperate with it. In addition, you can emphasize the after-sales quality assurance of the products, and ask how the company’s after-sales service is doing, and you can roughly estimate the strength of the machining plant.

Compared with other cooperative manufacturers, it is relatively easy to choose a zirconia ceramic machining manufacturer. As long as you can spend some effort to conduct an on-the-spot investigation, after understanding the basic situation of the other party, whether you can cooperate or not is still very easy to do. decided. Cooperate with reliable machining manufacturers, they provide products made of zirconia ceramics that can be reassuring. Be-Cu Ceramics is unanimously recognized in the industry for its professional ability, abiding by contracts and keeping promises.

About China Advanced Ceramic CNC Machining Company - Be-Cu

Manufacturer of precision machined components. Ceramic cnc machining components include high dielectric strength, electrical & corrosion resistance, & non-porous & non-shrinking properties.Manufacturer of high temperature fabricated and machinable ceramics including alumina, glass-ceramic, alumino-silicate, boron nitride and zirconium phosphate. Adhesives, coatings and potting compounds to 3200 degrees F,Air firing services for ceramics up to 1650 degrees C also available. Products include insulators, guides, washers, tubes, blocks, & rods for thermal, electrical, corrosion exposure, structural, wear, & semi-conductor operations. Services include machining to tolerances of +/- .0001, ultrasonic core drilling, centerless grinding, milling, & ID & OD threading.Surface grinding, dicing, OD (outer dia.) grinding, ID (inner dia.) grinding, centerless grinding, hole drilling, jig grinding, lapping, honing & polishing service are also available. Diamond grinding with dimensional tolerances of 5 microns & surface finishes of 0.2 microns (8 micro-in.) can be performed.Blanket orders and AutoCAD files & other 3d files accepted.Contact us for your machining ceramic project!

-

Metal Plating ZrO2 Zirconia Ceramic Parts

-

ZrO2 Structural Ceramic Semiconductor Parts

-

Alumina Ceramic Screw Type Parts

-

Cnc Machining Alumina Ceramic Screw Heating Pipe

-

Brushed Fishing Tackle Alumina Ceramic Accessories

-

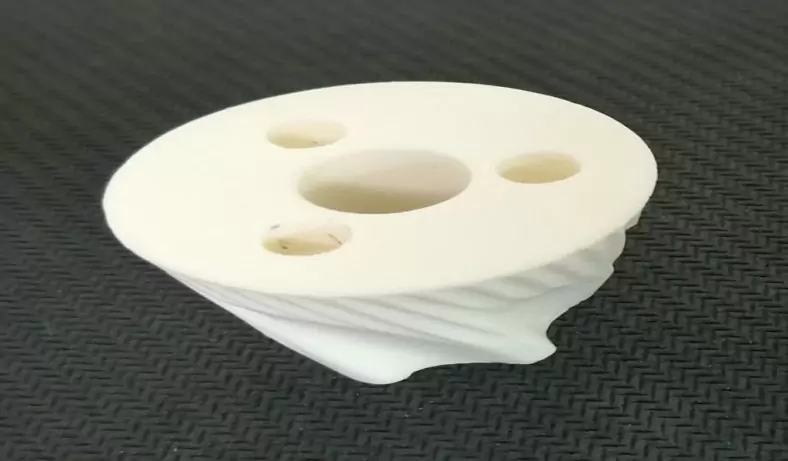

Winding Machine Alumina Ceramic Wire Wheel

-

Insulation Device Microcrystalline Ceramic Multi-Slot Ceramic Column

-

99 Alumina Ceramic Spool Insulator Sleeve

-

The Alumina Ceramic Ring Of Textile Machine Thread Passing Wheel

-

Isostatic Pressure Insulation Alumina Ceramic Column