Polyethylene and polyvinyl chloride are the two most popular polymer materials, widely used in industry and home use. They have unique characteristics such as strength, elasticity, chemical resistance, heat resistance, etc., making them indispensable in the production of various products.

In this article, we will introduce the basic properties of polyethylene and polyvinyl chloride, as well as their history, production methods, and industrial applications. We will also introduce different types of heating elements and equipment used to produce these material products.

#1 The Discovering History Of PVC And PET

The Discovery History Of PVC

Polyvinyl chloride was discovered by Friedrich Kratt and Emile Heinrich respectively in the early 20th century. However, due to the difficulty in controlling its properties and production costs, this material did not initially spread widely.

In 1926, a method for large-scale production of PVC was developed. The invention of this method is the key to the development of PVC production. The first batch of industrial facilities for large-scale production of polyvinyl chloride has been completed.

Since then, PVC has been widely used in various industries, including window profiles, pipes, cables, wallpaper, etc. Polyvinyl chloride is one of the most widely used polymer materials in the world today.

The Discovery History of PET

PET was discovered in the middle of the 20th century in Great Britain by scientist John Rexlor and in the USA by scientist Nat Wise. They were working on a new polymer that could replace glass in packaging and container manufacturing.

In 1941, Rexlor created the first PET sample, but this discovery went unnoticed until Wise discovered the same material in 1946 in the United States. Weiss used PET to create durable plastic bottles that have replaced glass bottles in various industries.Since then, PET has become widely used in a variety of industries, including beverage bottles, packaging films, textile fibers, and more. Today, polyethylene terephthalate is one of the most common packaging and container materials worldwide.

#2 The Brief Description Of Properties And Applications.

Polyethylene terephthalate (PET) is a transparent, durable, chemical and mechanical damage resistant polymer material. It is widely used in the production of beverage bottles, food packaging, medical products, cosmetics and household products, as well as fiber for the textile industry.

- Due to its unique properties, PET has become one of the most popular materials for packaging and containers worldwide. It has excellent transparency, allowing consumers to better see the products inside the package. At the same time, it is strong enough to withstand the transportation and storage of products.

- In the medical industry, PET is used to create various medical products such as syringes, infusion sets, urine and blood collection containers. It is also widely used in the production of household appliances, cosmetics and other household products.

- In the textile industry, PET is used to make fiber, which is then used to make a variety of textile products such as clothing, bedding, and furniture fabrics.

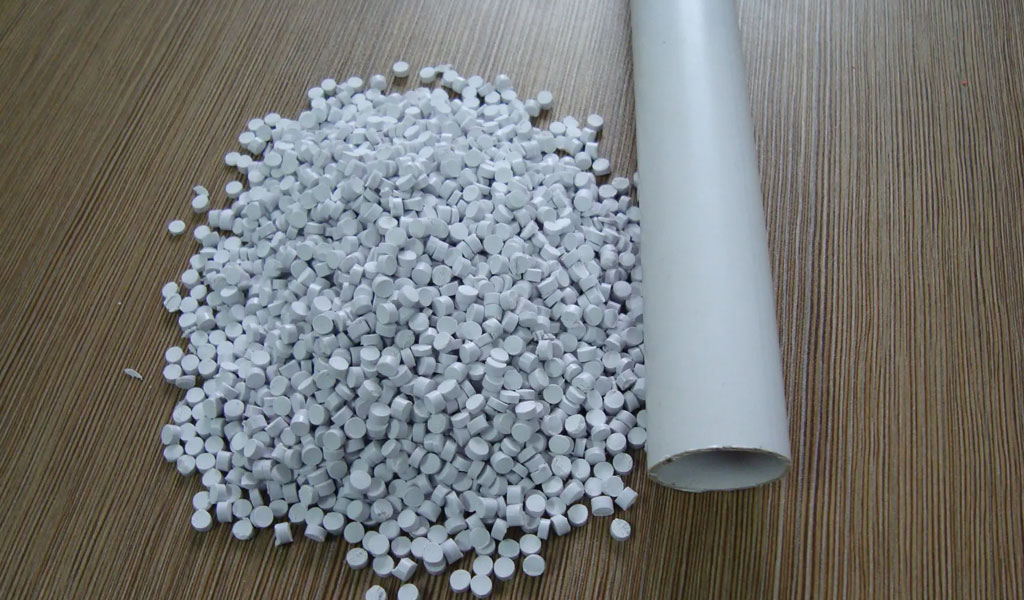

Polyvinyl chloride (PVC) is a high-strength plastic that is chemically, weather and UV resistant. It is widely used in the production of window and door profiles, siding, pipes and fittings for heating and ventilation systems.

PVC is also used to make electrical cables, films and wallpapers, as well as medical equipment and furniture. It is one of the most common plastics in industry and construction due to its strength, resistance to aggressive influences and durability.

#3 The Properties Comparison Of PVC And PET

As already mentioned, polyethylene terephthalate (PET) and polyvinyl chloride (PVC) are two different types of plastic, each with its own unique properties and applications.

PET has higher strength and impact resistance than PVC and is the best choice for packaging materials such as beverage bottles, food containers and other consumer goods. It is also widely used in the medical industry for the production of jars for storing medicines and injection syringes.

On the other hand, PVC is more chemical and weather resistant than PET and is used in window and door profiles, pipes, siding and other building materials, as well as in electrical products, medical equipment and furniture.

Thus, the choice between PVC and PET depends on the specific application and requirements for material properties such as strength, chemical and weather resistance, durability, etc.

#4 The Composition And Chemical Properties Of PVC & PET

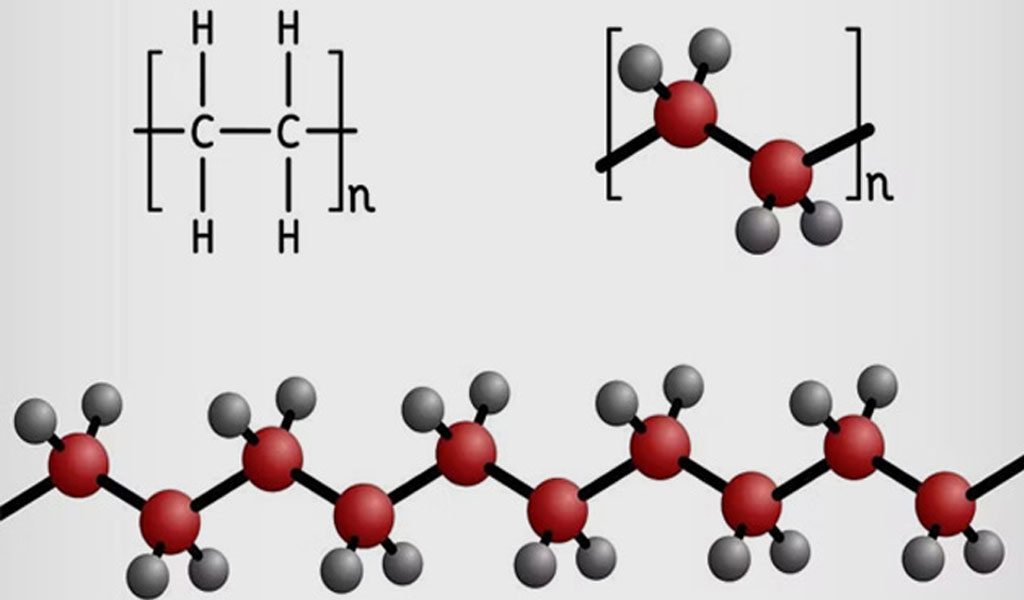

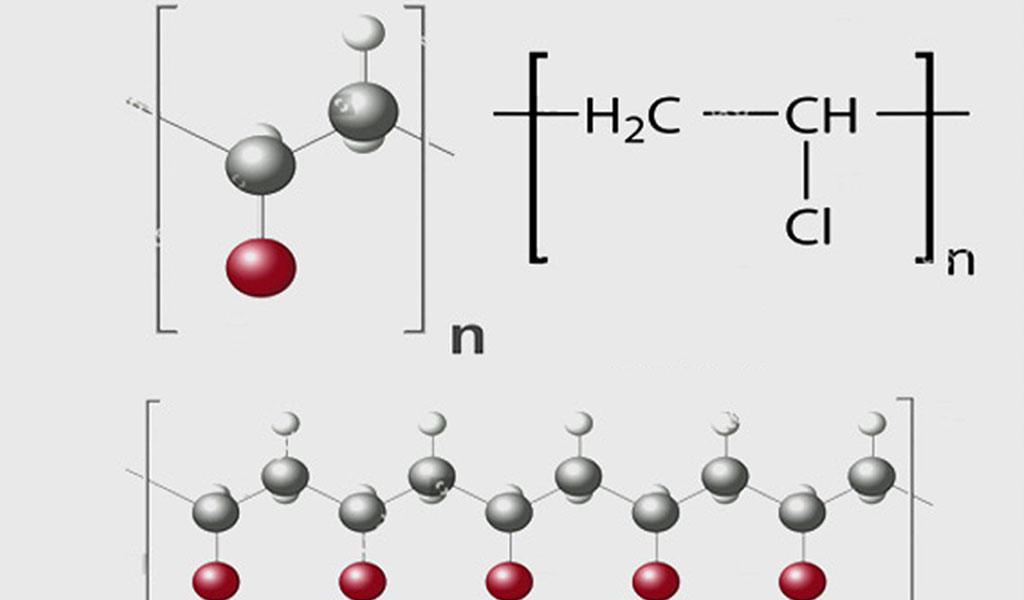

First, consider the composition and chemical properties of PVC. Polyvinyl chloride (PVC) is a polymer composed of vinyl chloride monomers. The PVC molecule has a spatial structure formed by bonds between carbon, hydrogen and chlorine atoms. For PVC, the molecular formula is usually written as -(CH2-CHCl)-, that is, the molecule contains alternating methylene and vinyl chloride groups.

As a result of the formation of additional bonds between PVC molecules, the material acquires high strength and rigidity, as well as good resistance to various chemicals and fire.

As for PET, it is a polymer that consists of ethylene terephthalate monomers. The PET molecule also has a spatial structure formed by bonds between carbon, hydrogen and oxygen atoms. For PET, the molecular formula is written as -(C10H8O4)-, that is, the molecule contains repeating blocks of terephthalic acid ester and ethylene glycol. Due to this structure, PET has high strength and rigidity, as well as good resistance to UV radiation, acids and alkalis.

It should be noted that the chemical properties of PVC and PET differ significantly. For example, PVC is resistant to oils, gasoline and some solvents, while PET is not subject to corrosion and has a low permeability to oxygen and carbon dioxide.

#5 The Production Methods Of PVC & PET

Polyethylene Production

For the production of polyethylene, the ethylene polymerization method is used. This process involves the use of a catalyst, heating elements and pressure. The catalyst activates ethylene and leads to the formation of polyethylene molecules, which are then converted into a polymer mass.

The production method of PET is called polymerization. It is based on the synthesis of ethylene terephthalate monomer into a high molecular weight polymer.

The process begins with mixing the monomers and adding a catalyst, after which the mixture is heated to a high temperature, usually around 280-300 degrees Celsius, in a reactor. Heating occurs with the help of heating elements, which are located inside the reactor and provide a uniform temperature distribution inside the reactor.

At this temperature, polymerization of the monomers in PET occurs. The reaction mass travels through the reactor and is cooled until it reaches a temperature at which the PET becomes solid. Then the resulting polymer is crushed in special mills and used to produce PET products.

The main features of the PET production process are the accuracy of temperature and pressure control in the reactor, as well as ensuring the uniformity of the thermal effect on the reaction mass. For this, various types of heating elements are used, which can be installed both inside the reactor and outside.

The PET production process is quite complex and requires highly skilled personnel, as well as the use of high-tech equipment, including various types of heating elements.

PVC Production

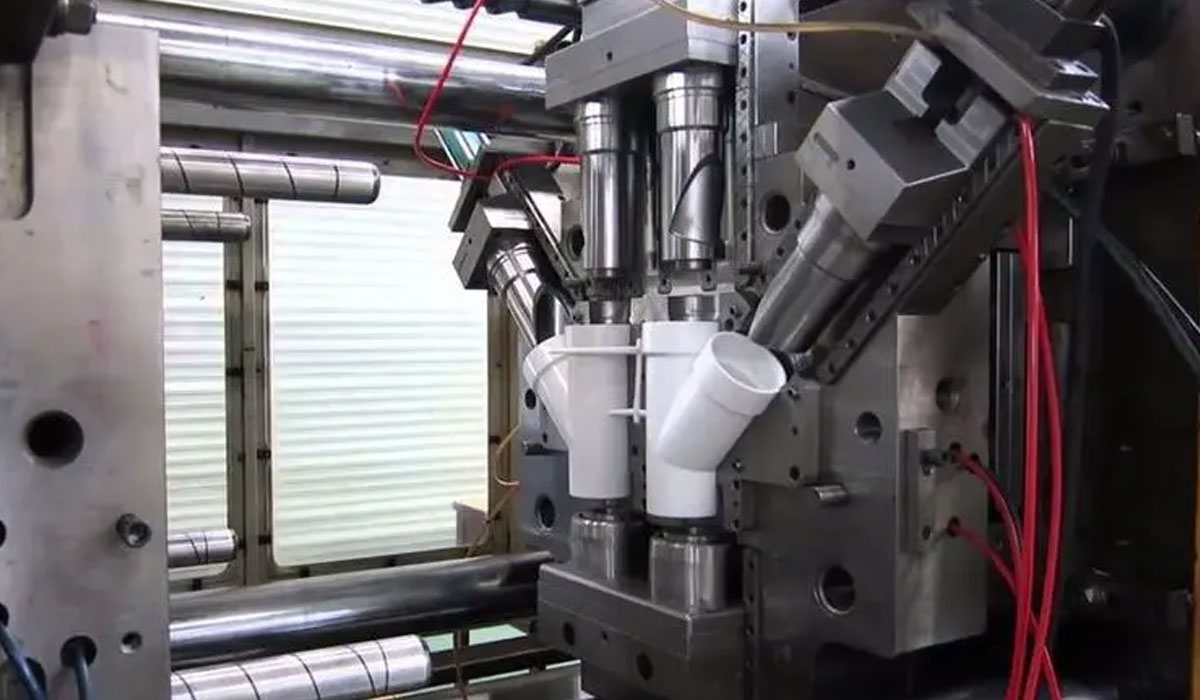

For the production of polyvinyl chloride, the process of vinyl chloride polymerization is used. This process also includes the use of a catalyst, heating elements and pressure. The catalyst stimulates the vinyl chloride polymerization reaction and leads to the formation of polyvinyl chloride molecules, which are then processed and used in the manufacture of various products.

PVC production methods are divided into two types: suspension and emulsion.

- The slurry method is the most common PVC production method. It is based on the bulk polymerization of an aqueous-alcoholic suspension of vinyl chloride monomer with the help of benzoyl peroxide and other ingredients such as stabilizers, plasticizers and heaters. In this process, heaters play a key role in creating and maintaining the required temperatures and pressures.

- The emulsion method is also used for the production of PVC, especially for the production of softer and more flexible types of PVC such as upholstery PVC. In this method, the vinyl chloride monomer is emulsified in water using emulsifiers and polymerized by the action of peroxide and other ingredients. Heaters also play a role in the process, helping to maintain the optimum temperature and speeding up the polymerization reaction.

Both methods of PVC production have their own characteristics and advantages depending on the specific production needs.

In both processes, heating is an important component to activate the reaction and increase the rate of polymerization. Heating elements play an important role in providing the required temperature and controlling its level during the production process.

#6 The Varieties And Classification Of PVC & PET

The Varieties Of PET:

- PET-A (amorphous polyethylene terephthalate);

- PET-G (homopolymer polyethylene terephthalate);

- PET-M (modified polyethylene terephthalate);

- PET-R (recycled polyethylene terephthalate).

PET Classification:

- Standard PET (optimum balance between strength and stiffness);

- Improved PET (high strength and impact resistance);

- Ultra-clean PET (used in the food packaging industry);

- PET barrier (coated to prevent oxygen from entering).

Varieties Of PVC:

- PVC-P (polyvinyl chloride-plastisol);

- PVC-L (polyvinyl chloride-latex);

- PVC-S (polyvinyl chloride suspension);

- PVC-K (polyvinyl chloride compound).

PVC Classification:

- Rigid PVC (used for the production of pipes, window profiles, exterior cladding of buildings);

- Flexible PVC (used for the production of cable products, car carpets and rugs, upholstered furniture);

- PVC with reduced toxicity (used for the production of medical and children’s equipment);

- PVC with reduced flammability (used in the construction industry).

#7 The Comparison Of PET And PVC Physical Properties

- Strength: PET has high tensile and flexural strength, while PVC is more flexible and less durable.

- Resilience: PVC is more resilient than PET. It has high viscosity and is able to return to its original shape after deformation.

- Heat resistance: PET has higher heat resistance than PVC. PET can withstand higher temperatures and does not soften when heated.

- Chemical resistance: PET is more chemical resistant than PVC. It does not break down when exposed to most chemicals, while PVC can dissolve in some organic solvents.

- Transparency: PET is more transparent than PVC. It has a higher light refractive index and transmits light better.

However, it is worth noting that each material has its own unique properties and applications, and the choice between them depends on the specific task and conditions of use.

#8 The Application Of PET And PVC

Polyethylene and polyvinyl chloride are widely used in various industries due to their unique properties. They are used in the production of packaging materials, including films, bags and bottles. Polyethylene is also used in the production of pipes, insulation materials, toys, car parts and many other products.

Polyvinyl chloride is widely used in construction, where it is used to produce window profiles, doors, pipes and other building materials. It is also used in the automotive industry for the production of parts such as instrument panels and interior trim, as well as in the production of electrical cables and insulating materials.

#9 Heaters For The Manufacture Of PET And PVC Products

In the production of plastic products, including polyethylene and PVC products, heaters play an important role. Ring heaters are used for extruders and injection molding machines, cartridge heaters are used for casting, infrared ceramic and quartz heaters are used for molding and other processes. Thanks to our company, which produces all types of electric heaters for the production of plastic products, the production of plastic products becomes more efficient and economical.

#10 Conclusion

As we have seen throughout this article, polyethylene and polyvinyl chloride are among the most common polymers in the world, used in various industries. Both materials have their own advantages and disadvantages, which are determined by their chemical composition, molecular structure and physical properties.

The production methods of polyethylene and PVC also differ, and various heating elements are used in the production process, such as ring heaters for extruders and injection molding machines, cartridge heating elements for casting, infrared ceramic and quartz heaters for molding.

Despite differences in properties and production methods, both polyethylene and polyvinyl chloride have a wide range of industrial applications, including packaging, construction, automotive and other industries.

Our company produces various types of heaters for the production of plastic products, which makes our products indispensable for many manufacturers. Thanks to our heating elements, the production process becomes more efficient and economical.

Thus, polyethylene and polyvinyl chloride continue to be among the most important materials in the industry and their use will only increase in the future.