Fiberglass itself is a reinforcing material, usually pultruded into fiberglass tubes using epoxy resin as a matrix. Fiberglass pipes have a series of advantages such as high strength, corrosion resistance, friction resistance, insulation, and antistatic. It can be used in the environment of -40℃~150℃. If better-performing resin is used, the fiberglass tube can withstand high temperatures of 180℃. Fiberglass tubes are mainly used in the electronic and electrical fields.Carbon fiber composite material is composed of carbon fiber reinforcement and matrix resin. It has high temperature resistance, shock absorption, high strength, light weight, small thermal expansion coefficient, good damage safety, and can be integrally formed.

It has many advantages and is used in many fields. When producing carbon fiber composite products, the choice of process is very important. The production process of carbon fiber composite materials can be divided into three categories:

1. Molding

Including compression molding, resin transfer molding, injection molding, cold pressing, etc. Compression molding is to press the preform at a specific temperature and pressure; resin transfer molding is to inject resin into a mold covered with carbon fiber material, and cure and release; injection molding is to inject carbon fiber prepreg into a closed mold ; Cold press forming is to allow carbon fiber composites to cure exothermically at room temperature.

2. Contact Molding

Including hand lay-up molding, injection molding, vacuum bag molding, pressure bag molding, etc. They feature no or only low forming pressure.

3. Other Molding Methods

Including winding molding, pultrusion molding, etc., winding method can also be subdivided into wet winding, dry winding and semi-dry winding; pultrusion method is to pull carbon fiber through liquid resin mixture. The selection of the specific process should be determined according to the performance of the product, the production quantity and the predetermined price.

For example, carbon fiber tubes are mostly micro manufactured by winding process, pultrusion process is suitable for producing profiles of various cross-sectional shapes, and special-shaped parts with high precision requirements and a large number of demands can be produced by molding process.

Be-cu Prototype is a professional carbon fiber production and machining unit that started early and developed rapidly in China. Its scientific research team has been focusing on the research and development and production of carbon fiber composite materials for more than ten years. , electromagnetic shielding and other carbon fiber composite materials with different properties, to achieve its wider application in aerospace, automotive high-speed rail, military and other fields.

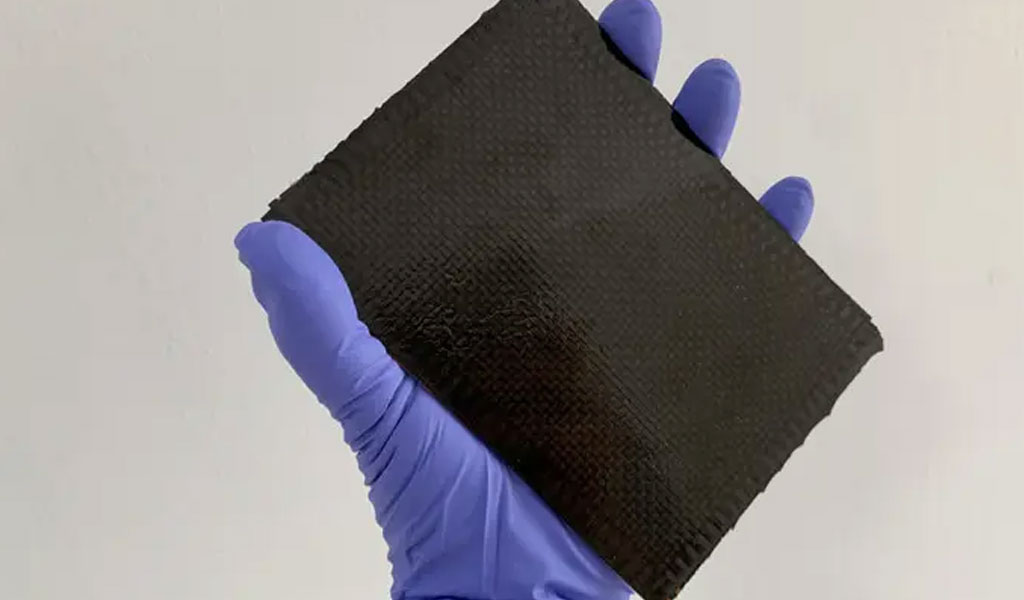

Carbon fiber composite material is composed of carbon fiber reinforcement and matrix resin. It has high temperature resistance, shock absorption, high strength, light weight, small thermal expansion coefficient, good damage safety, and can be integrally formed. It has many advantages and is used in many fields. . When producing carbon fiber composite products, the choice of process is very important.

ISO 9001 certified. BE-CU Prototype Offering CNC machining carbon fiber and other manufacturing services for carbon fiber marterial. Various capabilities include notching, labeling, drilling carbon fiber, grinding, laser cutting carbon fiber, finishing, plating, marking, CNC milling carbon fiber and turning carbon fiber.We stock high quality 3k carbon fiber sheet in a variety of thickness, types and finish. Its a great material used in applications where light weight and strength are needed such as drones. Unlike other workshops, we have no min order and are often filling orders with a single part. We also don’t make you pay for the full sheet and you only get charged for what is used. With a large selection of material, you should find everything you need to make your project come to life. We are also able to handle larger production runs and provide a competitive pricing. If we don’t have the material or finish you require, we are more the willing to look at bringing it in for you.

What Is Carbon Fiber?Carbon fiber is made of polyacrylonitrile (PAN) (or pitch, viscose) and other organic fibers by carbonization (removal of most elements except carbon) by pyrolysis method under inert gas at high temperature above 1,000 °C. Inorganic polymer fibers with a carbon content of more than 90%.

-

3D Printing Continuous Fibres

-

3D Printing Short Fibre Filled Wires

-

Laser Cutting Carbon Fiber Positioning Keyboard

-

Cnc Turning Industrial Copper-Aluminum Clad Carbon Fiber Machinery Parts

-

Carbon Fiber Luggage Tag Ornaments

-

Laser Cutting Carbon Fiber Guitar Shape Crafts

-

Laser Cutting Carbon Fiber Drone Rack

-

Cnc Milling Carbon Fiber Finger Buckle