In actual production, the tools or appliances used to help users quickly, accurately and accurately check the dimensions of various parts and determine whether they meet the design dimensions are called inspection tools. Now carbon fiber composite materials are gradually used to make inspection tools.

As a special measuring tool, the inspection tool itself should have high precision, good dimensional stability, strong rigidity and convenient operation performance, and carbon fiber can well meet these requirements.

The working temperature of the carbon fiber inspection tool is high, and its thermal expansion coefficient is small, which can ensure the dimensional stability in an environment with a large working temperature difference, basically will not deform with the change of the working temperature, and ensure the operation accuracy. Carbon fiber is an excellent weight-saving material. Its density is only 1.7g/cm3, which is less than 1/4 of that of steel.

The inspection tool made is very light, and the operation is more convenient than metal inspection tools. While reducing weight, the mechanical properties of carbon fiber composites are also very prominent. Its tensile strength, flexural strength, and shear strength are better than most structural materials, and the higher the grade of carbon fiber, the more significant the mechanical properties are.

Carbon fiber inspection, also known as non-destructive testing (NDT) of carbon fiber composites, offers several advantages for ensuring the quality and integrity of these advanced materials. NDT techniques are used to inspect carbon fiber components without causing any damage, providing valuable information about potential defects or flaws. Some of the key advantages of carbon fiber inspection are:

Non-Destructive Nature

The primary advantage of carbon fiber inspection is that it is non-destructive, meaning it does not cause any harm or alteration to the inspected components. This is crucial for critical and high-value carbon fiber parts, as they can be thoroughly examined without compromising their structural integrity.

Detecting Internal Defects

Carbon fiber composites may have internal defects or delamination that are not visible on the surface. NDT methods, such as ultrasonic testing or X-ray inspection, can detect these hidden flaws, ensuring the safety and reliability of the components.

Quality Assurance

Carbon fiber inspection plays a vital role in quality assurance during the manufacturing process. By detecting defects or irregularities early on, manufacturers can take corrective actions and ensure that only defect-free components are delivered to customers.

Cost-Effective

NDT methods are generally cost-effective compared to destructive testing methods, which require the destruction of samples for analysis. Carbon fiber inspection helps save time and resources by identifying potential issues without the need for expensive and time-consuming destructive testing.

Real-Time Inspection

Many NDT techniques can provide real-time inspection results, allowing for immediate assessment of the component’s condition. This real-time feedback is especially valuable during the manufacturing process, as it enables timely adjustments and reduces the risk of producing defective parts.

Versatility

NDT methods offer a wide range of inspection techniques suitable for different carbon fiber components and structures. Techniques such as ultrasonic testing, radiography, thermography, and visual inspection can be tailored to specific inspection requirements.

In-Service Inspection

NDT methods can be used for periodic inspection and maintenance of carbon fiber components during their service life. This allows for the detection of degradation, damage, or wear over time, enabling proactive maintenance and preventing catastrophic failures.

Reduced Material Waste

Since NDT does not cause damage to the inspected parts, there is minimal material waste during the inspection process. This is particularly important for expensive and scarce carbon fiber materials.

Compliance with Standards

NDT methods are often specified in industry standards and regulations for inspecting critical components, ensuring compliance with safety and quality requirements.

Overall, carbon fiber inspection using non-destructive testing techniques offers numerous advantages, including preserving the integrity of components, detecting internal defects, reducing costs, ensuring quality, and facilitating in-service maintenance. It is a valuable tool in the production and maintenance of carbon fiber composites, contributing to their widespread use in various industries such as aerospace, automotive, marine, and sports equipment.

China Be-cu Prototype Material Technology Co., Ltd. is a carbon fiber product manufacturer with many years of rich production experience. Now the company has more than ten kinds of machining equipment such as large hot presses, hot presses, hydroforming tables, CNC high-speed milling machines, etc. The production of a series of carbon fiber products provides complete facilities.

ISO 9001 certified. BE-CU Prototype Offering CNC machining carbon fiber and other manufacturing services for carbon fiber marterial. Various capabilities include notching, labeling, drilling carbon fiber, grinding, laser cutting carbon fiber, finishing, plating, marking, CNC milling carbon fiber and turning carbon fiber.We stock high quality 3k carbon fiber sheet in a variety of thickness, types and finish. Its a great material used in applications where light weight and strength are needed such as drones. Unlike other workshops, we have no min order and are often filling orders with a single part. We also don’t make you pay for the full sheet and you only get charged for what is used. With a large selection of material, you should find everything you need to make your project come to life. We are also able to handle larger production runs and provide a competitive pricing. If we don’t have the material or finish you require, we are more the willing to look at bringing it in for you.

What Is Carbon Fiber?Carbon fiber is made of polyacrylonitrile (PAN) (or pitch, viscose) and other organic fibers by carbonization (removal of most elements except carbon) by pyrolysis method under inert gas at high temperature above 1,000 °C. Inorganic polymer fibers with a carbon content of more than 90%.

-

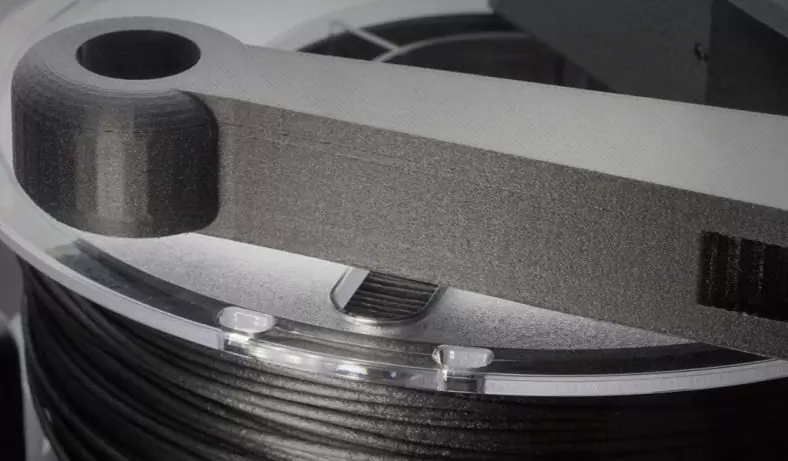

3D Printing Continuous Fibres

-

3D Printing Short Fibre Filled Wires

-

Laser Cutting Carbon Fiber Positioning Keyboard

-

Cnc Turning Industrial Copper-Aluminum Clad Carbon Fiber Machinery Parts

-

Carbon Fiber Luggage Tag Ornaments

-

Laser Cutting Carbon Fiber Guitar Shape Crafts

-

Laser Cutting Carbon Fiber Drone Rack

-

Cnc Milling Carbon Fiber Finger Buckle