We often talk about the advantages of carbon fiber products. It is precisely because of these advantages, such as light weight, high strength, fatigue resistance, corrosion resistance, etc., that carbon fiber products shine in many industries. It is about the application of carbon fiber products in the field of medical equipment, combined with the actual carbon fiber products of the Be-cu prototype to tell you.

Carbon fiber products in the field of medical components are mainly related to the characteristics of carbon fiber composite materials. The carbon fiber products produced are also based on this. Let’s look at several common carbon fiber products.

Carbon Fiber Medical Stretcher

The stretcher is a piece of equipment that is frequently used in hospitals, especially in some rescue work. In the use of stretchers, the Be-cu prototype is used in the production of carbon fiber stretchers. It is a folding stretcher, which is easy to move. The whole stretcher is designed The requirements for the top and the connection are relatively high, and the entire stretcher has a high bearing capacity, which ensures the convenience of use and reduces the burden on medical staff when carrying the stretcher.

Another is the particularity of carbon fiber materials, the bending of different metal materials, the carbon fiber medical stretcher has extremely high bending performance, so if the patient is very heavy, it will not break immediately, and a few breakage will occur. So there is no immediate situation, which brings advantages for the transfer of patients.

Carbon Fiber Medical Bed Board

Carbon fiber medical bed board is also a common product in carbon fiber medical equipment. It is mainly used for testing beds. On the one hand, it has high strength and can support high weight. On the other hand, it has excellent corrosion resistance. Contact with medical chemicals, so the medical bed board needs to have very good chemical stability and strong corrosion resistance. Under the contact of drugs such as alcohol or blood stains, there will be no corrosion, which can greatly improve the entire service life.

Carbon Fiber CT Bed Plate

In the hospital, in order to accurately understand the patient’s condition, CT testing is required. The X-ray is mainly used in the CT test. The traditional phenyl ether version is used in the X-ray, which has poor penetration and shadows in the imaging. , can only increase the radiation dose of X-rays, on the one hand, it will cause damage to patients, and on the other hand, there are hidden dangers to our medical staff. After the carbon fiber CT bed plate is used, because of the high-efficiency X-ray transmission effect, the radiation Reduced, the imaging is also clearer, which is more conducive to doctors to understand the condition and carry out targeted treatment and improvement.

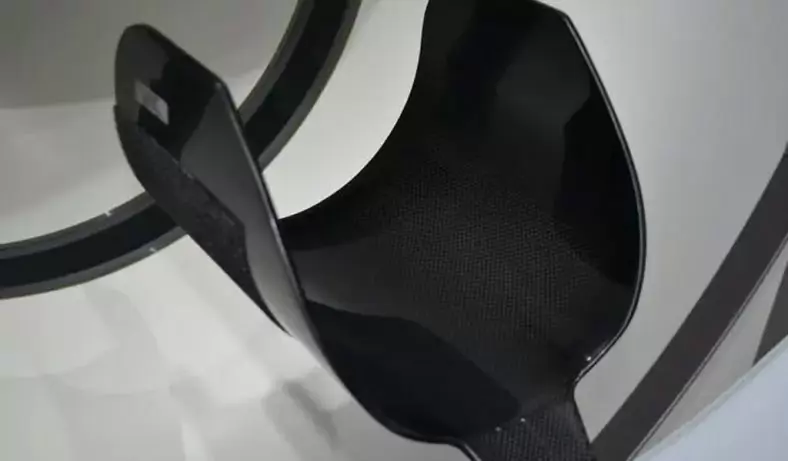

On the CT bed, there are also carbon fiber CT head support and other supporting products. On the one hand, it is also for high X-ray penetration, and on the other hand, the carbon fiber product has a good texture in contact. nice feeling.

Carbon Fiber Wheelchair

A wheelchair can make patients who cannot walk on their own move on a wheelchair. The wheelchair needs to have a solid structure to support the weight of the human body. However, if it is made of metal, it can meet the advantage of strength, but this will make the weight of the wheelchair very high, and the wheelchair will be inconvenient to use. Then the wheelchair made of carbon fiber can have a tensile strength seven times that of steel, but the density Only one-fifth of steel, which is the material of choice for wheelchairs.

Carbon Fiber Prosthesis

Carbon fiber prostheses need to have very good structural stability, good fatigue resistance, and also need to have strong biocompatibility. Carbon fiber composite materials can meet this requirement very well. Because of the light weight, it is not easy to bring a strong sense of weight in use, and it is also better to use. It can have a strong sense of follow-up and is very convenient.

The above carbon fiber products are produced by Be-cu prototypes, which have been produced for decades in the carbon fiber product production industry. The products produced are definitely not only these, but also carbon fiber products used in many industries. The reason is because The advantages of high performance of carbon fiber products. China Be-cu Prototype Material Technology Co., Ltd. has ten years of rich experience in the field of carbon fiber, mainly engaged in the production and machining of carbon fiber sheets, pipes and products. With complete molding equipment and perfect machining machines, it can complete the production of various types of carbon fiber products and better satisfy customers. Welcome to consult.

ISO 9001 certified. BE-CU Prototype Offering CNC machining carbon fiber and other manufacturing services for carbon fiber marterial. Various capabilities include notching, labeling, drilling carbon fiber, grinding, laser cutting carbon fiber, finishing, plating, marking, CNC milling carbon fiber and turning carbon fiber.We stock high quality 3k carbon fiber sheet in a variety of thickness, types and finish. Its a great material used in applications where light weight and strength are needed such as drones. Unlike other workshops, we have no min order and are often filling orders with a single part. We also don’t make you pay for the full sheet and you only get charged for what is used. With a large selection of material, you should find everything you need to make your project come to life. We are also able to handle larger production runs and provide a competitive pricing. If we don’t have the material or finish you require, we are more the willing to look at bringing it in for you.

What Is Carbon Fiber?Carbon fiber is made of polyacrylonitrile (PAN) (or pitch, viscose) and other organic fibers by carbonization (removal of most elements except carbon) by pyrolysis method under inert gas at high temperature above 1,000 °C. Inorganic polymer fibers with a carbon content of more than 90%.

-

3D Printing Continuous Fibres

-

3D Printing Short Fibre Filled Wires

-

Laser Cutting Carbon Fiber Positioning Keyboard

-

Cnc Turning Industrial Copper-Aluminum Clad Carbon Fiber Machinery Parts

-

Carbon Fiber Luggage Tag Ornaments

-

Laser Cutting Carbon Fiber Guitar Shape Crafts

-

Laser Cutting Carbon Fiber Drone Rack

-

Cnc Milling Carbon Fiber Finger Buckle