Ceramic molding is an important process link in ceramic production. The more common ceramic machining methods are generally: grinding, polishing, ultrasonic machining and laser machining.

Ceramic Machining Methods

Be-Cu Ceramics is the source manufacturer specializing in the production and machining of ceramics. The products are of good quality and are loved by customers and friends. The machining methods used are the most common. Then, the professional and technical personnel of Be-Cu ceramics will explain to you some ceramic machining methods.

- First, the first method of grinding: a process of completing rapid thinning, using an abrasive particle coated or pressed on the grinding tool, and the relative movement of the grinding tool and the workpiece under a specific pressure for the surface Finishing.

- The second method of polishing: the use of mechanical, chemical or electrochemical action to make the surface of the workpiece smooth, so as to obtain a bright and smooth surface. Polishing can remove the flaws, scratches, grinding lines and other machining marks left by each previous process. Polishing also fills in surface pores, scratches and other imperfections, thereby increasing resistance to fatigue and corrosion.

- The third method is ultrasonic machining: the end face of the tool vibrating with ultrasonic frequency is used to impact the suspended abrasive particles in the working fluid, and the surface of the workpiece is hit and polished by the abrasive particles to complete the surface treatment of the workpiece. It is suitable for machining different hard and brittle materials, especially non-conductive materials and semiconductor materials that cannot be processed by EDM and electrolytic machining, and this machining method can obtain better quality.

- The fourth method of laser machining: also known as “radium engraving”, a surface treatment method that uses light energy to be focused by a lens and has a high energy density at the focus, and is processed by photothermal effect. It has a wide range of applications, can process almost any material, and uses non-contact machining without extreme extrusion or machine stress on the material.

Nowadays, it is widely used in industrial ceramic machining. In the ceramic machining industry, there are four common ceramic machining methods: grinding, polishing, ultrasonic machining, laser machining, etc. Be-Cu Ceramics has advanced technology and precision equipment, and has many years of professional application experience and leading solutions. The products are mainly used in new energy, semiconductor manufacturing, automobile manufacturing, medical equipment, automation, etc. Be-Cu Ceramics strives to create success for customers and become a trusted partner of customers.

About China Advanced Ceramic CNC Machining Company - Be-Cu

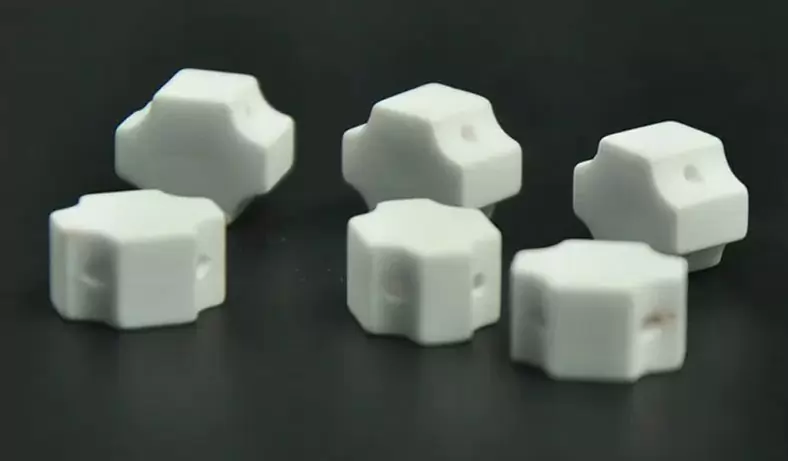

Manufacturer of precision machined components. Ceramic cnc machining components include high dielectric strength, electrical & corrosion resistance, & non-porous & non-shrinking properties.Manufacturer of high temperature fabricated and machinable ceramics including alumina, glass-ceramic, alumino-silicate, boron nitride and zirconium phosphate. Adhesives, coatings and potting compounds to 3200 degrees F,Air firing services for ceramics up to 1650 degrees C also available. Products include insulators, guides, washers, tubes, blocks, & rods for thermal, electrical, corrosion exposure, structural, wear, & semi-conductor operations. Services include machining to tolerances of +/- .0001, ultrasonic core drilling, centerless grinding, milling, & ID & OD threading.Surface grinding, dicing, OD (outer dia.) grinding, ID (inner dia.) grinding, centerless grinding, hole drilling, jig grinding, lapping, honing & polishing service are also available. Diamond grinding with dimensional tolerances of 5 microns & surface finishes of 0.2 microns (8 micro-in.) can be performed.Blanket orders and AutoCAD files & other 3d files accepted.Contact us for your machining ceramic project!

-

Metal Plating ZrO2 Zirconia Ceramic Parts

-

ZrO2 Structural Ceramic Semiconductor Parts

-

Alumina Ceramic Screw Type Parts

-

Cnc Machining Alumina Ceramic Screw Heating Pipe

-

Brushed Fishing Tackle Alumina Ceramic Accessories

-

Winding Machine Alumina Ceramic Wire Wheel

-

Insulation Device Microcrystalline Ceramic Multi-Slot Ceramic Column

-

99 Alumina Ceramic Spool Insulator Sleeve

-

The Alumina Ceramic Ring Of Textile Machine Thread Passing Wheel

-

Isostatic Pressure Insulation Alumina Ceramic Column