According to ISO regulations, when describing the motion of a CNC machine tool, a right-handed rectangular coordinate system is used; the coordinate axis parallel to the main shaft is defined as the z axis, and the rotation coordinates around the x, y, and z axes are A, B, and C, respectively. The movement of each coordinate axis can be realized by the table or the movement of the tool, but the direction is defined by the movement direction of the tool relative to the workpiece. Usually five-axis linkage refers to the linear interpolation movement of any 5 coordinates among x, y, z, A, B, and C.

In other words, five axes refer to the three moving axes of x, y, and z plus any two rotating axes. Compared with the common three-axis (x, y, z three degrees of freedom) machining, five-axis machining refers to the processing of parts with complex geometric shapes. The machining tool needs to be positioned and connected in five degrees of freedom.

The machine tool used for five-axis machining is usually called a five-axis machine tool or a five-axis machining center. Five-axis machining is often used in the aerospace field to process body parts, turbine parts and impellers with free-form surfaces. The five-axis machine tool can process different sides of the workpiece without changing the position of the workpiece on the machine tool, which can greatly improve the processing efficiency of prismatic parts.

The Detail Of BE-CU 5 Axis cnc machining Company

As an experienced and professional machine shop specialized in CNC manufacturing for many years, BE-CU.COM is capable of precision 5 axis CNC machining services and 5 axis milling. Whether you are in need of high-quality and precise metal or plastic components, we can provide 5 axis machining parts to worldwide clients for a variety of industries including automotive, medical, military, aerospace, mechanical, machine tool, high-tech, and more, with excellent machining and programming skills, as well as 5 axis CNC machining center. No matter how complex the CNC machining parts, each step will be executed with a rigorous attitude, to deliver exceptional 5 axis machining components that demonstrate the highest quality standards. Even though any problems during the process, we’ll keep running the job and make adjustments until all the issues are addressed.If you require a well-established and cost-effective CNC machining company to take over your project, BE-CU can achieve your expectation.

-

5 Axis CNC Machining Medical Olecranon Plate

-

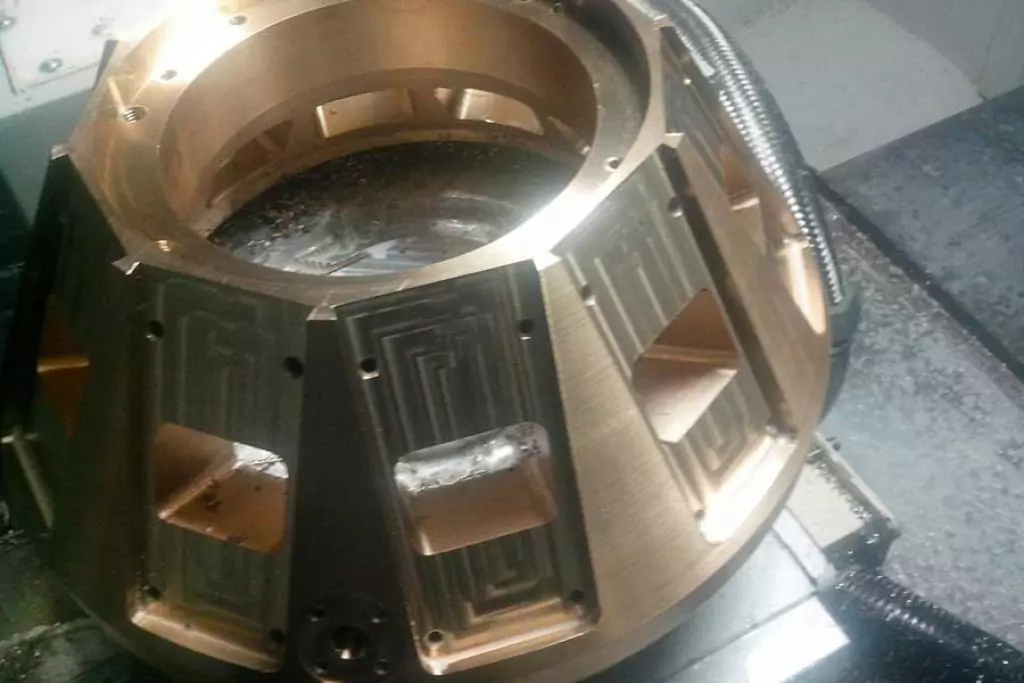

5 Axis CNC Machining Spiral Bevel Gear Mold

-

Small Precision Injection Molding Inserts

-

5 Axis Machining Aluminum-Magnesium Alloy Water Aerator Impeller

-

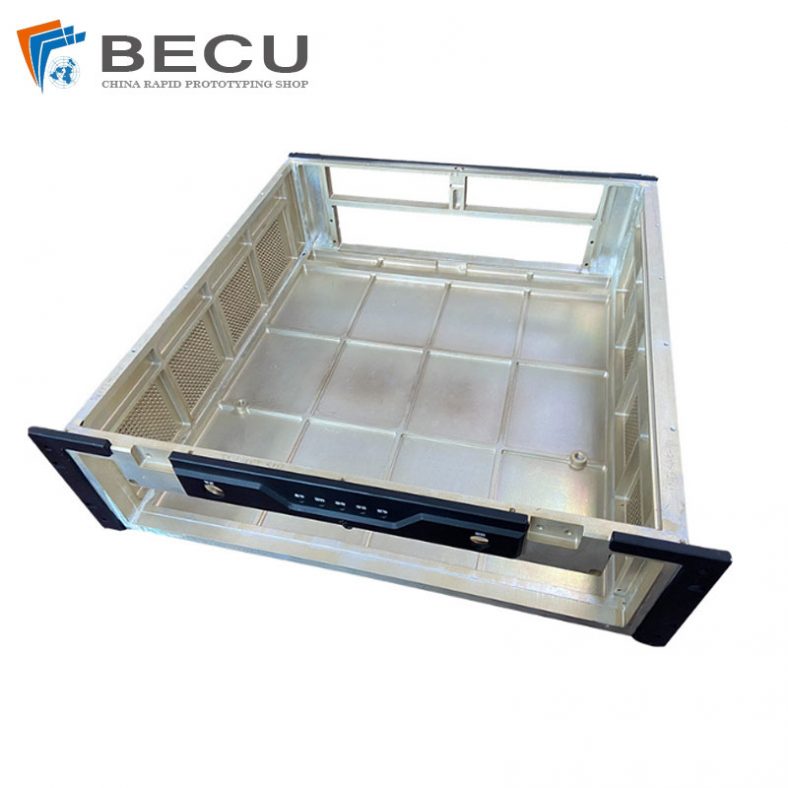

Precision Machining 6063 Aluminum Military Computer Server Chassis

-

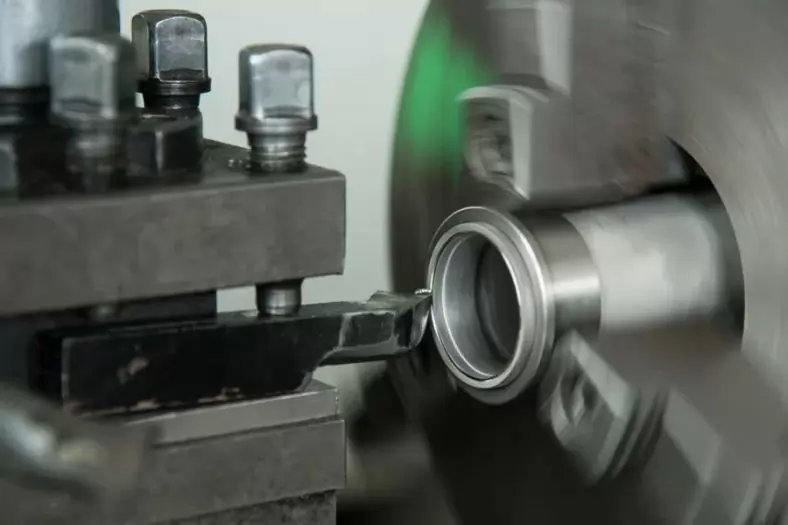

CNC 6063 Aluminum Automotive Motor End Cover

-

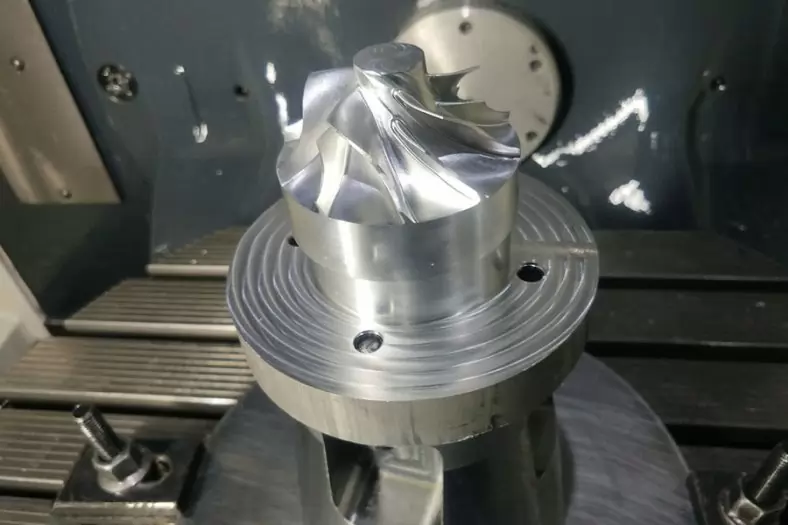

5 Axis CNC Machining Pump Impeller

-

3-Way Centrifugal Compressor Closed Impeller By 5 Axis Machining

The Type Of 5 Axis Cnc Machining

Cradle type, vertical type, horizontal type, NC table+NC indexing head, NC table+90°B axis, NC table+45°B axis, NC table+A axis°, non-orthogonal, two axis NC spindle, etc.

The Strategic Value Of 5 Axis Cnc Machining

The equipment manufacturing industry is the cornerstone of a country’s industry. It provides important means for the development of new technologies, new products, and modern industrial production. It is an indispensable strategic industry. Even the developed and industrialized countries attach great importance to it. In recent years, with the rapid development of my country’s national economy and the needs of national defense construction, there has been an urgent large-scale demand for high-end CNC machine tools. Machine tools are a symbol of the level of manufacturing in a country. The highest level of the machine tool manufacturing industry is the five-axis linkage CNC machine tool system, which, in a sense, reflects a country’s industrial development level. For a long time, Western industrialized countries headed by the United States have always regarded the five-axis linkage CNC machine tool system as an important strategic material and implemented an export license system. Especially during the Cold War, a blockade and embargo were imposed on China, the former Soviet Union and other socialist camps.

Military-loving friends may know the famous “Toshiba Incident”: At the end of the last century, Toshiba of Japan sold several five-axis CNC milling machines to the former Soviet Union. As a result, the former Soviet Union used to make submarine propulsion propellers to several grades. So that the sonar of the American butterfly ship could not monitor the sound of the submarine, so Toshiba of the United States violated the strategic material embargo policy and must punish Toshiba. It can be seen that the five-axis linkage CNC machine tool system has a decisive influence on a country’s aviation, aerospace, military, scientific research, precision equipment, high-precision medical equipment and other industries. It is generally believed that the five-axis linkage CNC machine tool system is the only means to solve the processing of impellers, blades, marine propellers, heavy generator rotors, steam turbine rotors, large diesel engine crankshafts, and so on. Therefore, whenever people encounter unsolvable problems in the design and development of complex curved surfaces, they often turn to the five-axis CNC system for help. Because the five-axis linkage CNC machine tool system is very expensive, coupled with the difficulty of NC program production, it is difficult for the five-axis system to be applied to civilians. However, in recent years, with the breakthrough development of computer-aided design (CAD) and computer-aided manufacturing (CAM) systems, many Chinese CNC companies such as Shanxing Company have launched five-axis linkage CNC machine tool systems, breaking foreign technology. The blockade has occupied the highest point of this strategic industry and greatly reduced its application costs, thus ushering in a new era in China’s equipment manufacturing industry! The development of modern science represented by information technology has injected strong impetus into the equipment manufacturing industry, and at the same time put forward stronger requirements for it, highlighting that the machinery and equipment manufacturing industry, as a carrier of high-tech industrialization, is promoting the technological progress and industry of the entire society. An irreplaceable basic role in upgrading.

As the driving force for national economic growth and technological upgrading, the machinery and equipment manufacturing industry, marked by five-axis linkage, will progress together with the development of high-tech and emerging industries.

The Diffenerce Of 2 Axis、3 Axis And 5 Axis CNC Machining

A 2 axis CNC machining system has the ability to modify objects on a plane. This plane has only two coordinate systems, the x and the y axis.

Objects can be moved on a plane. If the plane is upright then an object can be modified top to bottom and left and right or forward and backward.

On a 3 axis CNC machine, an object can be modified in space. It can be modified, left and right, top to bottom, and forward and back. You may be wondering, isn’t a 3 axis CNC machine enough to handle any given object.

Since it can modify an object in space then it must be able to transform an object at any given point. All this is correct but there is still a need for 5 axis CNC machining. Why?

On a 2 axis CNC machine, you can modify objects in a plane. On a 3 axis CNC machine, you can modify objects in space. On a 4, 5, 6, and so on and so forth axis CNC machine, you’ll be able to modify an object on several axes. Modifying an object on the x, y, and z planes may not be enough to create a perfect sphere.

Maybe a 45 degree angle axis will help in smoothening out the sphere. Going further an opposite 45 degree angle axis may also help do the job and so on and so forth.

The more axes on a CNC machine translates into a more complex piece of equipment. For 5 axis CNC machining equipment, you can take advantage of the extra two axes aside from the x, y, and z planes. If you are making a piece of art, you can rotate the object in two more ways than the usual x, y, and z movements.

The extra axes may be a circular axis, a diagonal axis, or whatever. As long as the extra axes help in the production of the final product, you can always have a 5 axis CNC machining tool handy.

The extra axes on a 5 axis machine are commonly called the Q and the B axis. The Q axis is normally associated with the rotation of the product whilst the B axis is associated with the tilting of the product. This is the nomenclature that is used in many 5 axis machines but it can always vary from machine to machine.

If you are having a hard time picturing what 5 axis CNC machining is all about then think of an airplane. Imagine the number of ways it can move in the air. First, think about the plane moving forward in the forward-backward plane.

This is the first movement and your first axis. Second, think about the plane going up and down in the altitude plane. This is the second movement and your second axis. Third, think about the plane turning left and turning right. This is the third movement and your third axis. Here comes the tricky part. Now you have to imagine the plane rolling like a barrel. This is the fourth movement and your fourth axis. When a plane rolls from being upright to being upside down, its axis is entirely different from the other three.

The fifth movement is even trickier. When a plane lands, imagine the nose tilting upward but not increasing in altitude. This is the fifth movement and it is your fifth axis. The 5 axis CNC machining equipment can modify an object in the same manner that the plane moves around space.

With 5 axis CNC machining technology, you can make objects like you’ve never expected.