carbon fiberIt has very good properties, especially its high strength and modulus of elasticity. Such fibers, which are rarely used alone, are often impregnated or filled with resins as reinforcements for composite materials. The cutting-edge carbon fiber composite materials usually use long fibers. First, the long fibers are woven into fabrics, and then dipped in resin for use. The following editor will talk about this in detail.

To manufacture carbon fiber reinforced composite materials , carbon fibers are usually impregnated with matrix resin, and then heated to obtain a semi-cured sheet-like intermediate matrix material, which is called a preformed material.

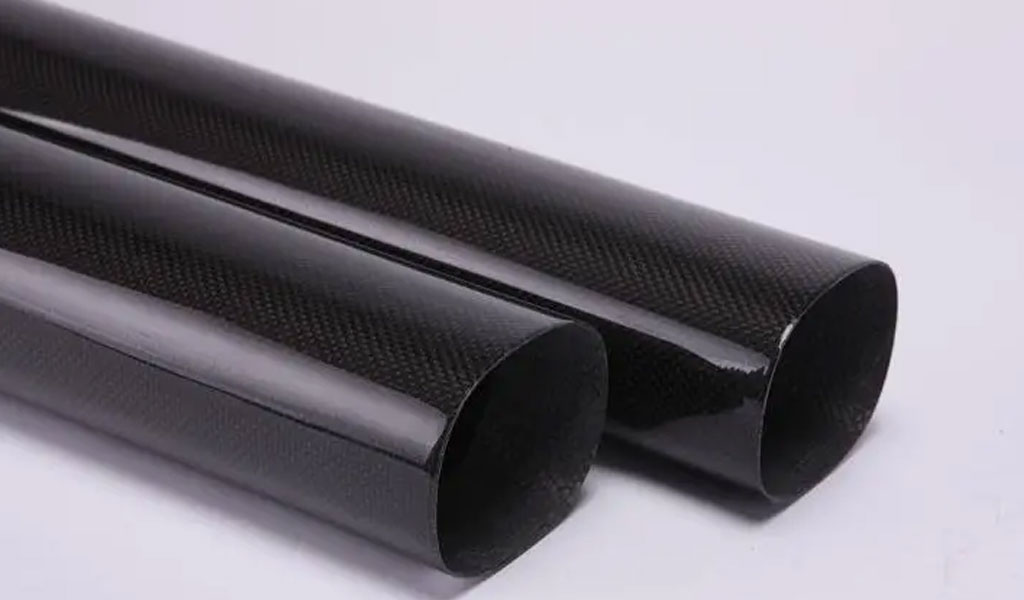

Depending on the purpose, it is formed in a press or autoclave, then wound onto the mandrel of a long-fiber winder, and thermally cured to form a tubular product.The resin used in the matrix is basically epoxy resin.Composite materials are composed of two or more materials with different properties, which are macroscopically composed of materials with new properties through physical or chemical methods.

Various materials complement each other in terms of performance, creating a synergistic effect, making the overall performance of composite materials better than the original component materials and meeting various different requirements.

Carbon Fiber Composite Materials

Carbon fiber reinforced resin-based composite materials are a new type of material that uses organic polymer materials as the matrix and carbon fiber as the reinforcing material. It is prepared through a composite process and has significantly better properties than the original components. It has high specific strength, high specific It has become one of the most important aviation structural materials due to its characteristics such as modulus, fatigue resistance, corrosion resistance, strong designability, easy large-area integral molding, and special electromagnetic properties.

The matrix resin used in carbon fiber reinforced resin matrix composite materials is mainly divided into two categories, one is thermosetting resin and the other is thermoplastic resin. Thermosetting resins are composed of reactive low molecular weight prepolymers or high molecular weight polymers with active groups. During the molding process, they are cross-linked and polycondensed under the action of a curing agent or heat to form an infusible and insoluble cross-linked structure. Commonly used ones include epoxy resin, phenolic resin, bismaleimide resin, etc. Thermoplastic resins are composed of linear high molecular weight polymers that dissolve and melt under certain conditions and undergo only physical changes. Commonly used ones include polyethylene, nylon, polyetheretherketone, etc.

Carbon Fiber Reinforced Ceramic Matrix Composite Materials

Ceramics have excellent corrosion resistance, wear resistance, high temperature resistance and chemical stability, and are widely used in industrial and civil products. However, its Achilles heel is that it is brittle and sensitive to minor defects such as cracks, pores and inclusions. Reinforcing ceramics with carbon fiber can effectively improve the toughness, change the brittle fracture morphology of ceramics, and prevent the rapid propagation and expansion of cracks in the ceramic matrix.

At present, the more mature carbon fiber reinforced ceramic materials at home and abroad are carbon fiber reinforced silicon carbide materials. Because of its excellent high temperature mechanical properties, it does not require additional insulation measures when serving at high temperatures. Therefore, it is widely used in aerospace engines, reusable aerospace vehicles and other fields. Has a wide range of applications.

Carbon/Carbon Composite Materials

Carbon/carbon composite material is the abbreviation of carbon fiber reinforced carbon matrix composite material and is also an advanced composite material. It is composed of carbon fiber or reinforced carbon-based composite materials such as fabric and braid. Carbon/carbon composite materials are mainly composed of various types of carbon, namely fiber carbon, resin carbon and deposited carbon. This composite material composed entirely of artificially designed and manufactured pure carbon elements has many excellent properties.

In addition to high strength, high rigidity, dimensional stability, anti-oxidation and wear resistance, it also has high fracture toughness. and pseudoplasticity. Especially in high-temperature environments, it has high strength, does not melt or burn, and only ablate uniformly. This is incomparable to any metal material. Therefore, it is widely used in high-tech fields such as missile warheads, solid rocket motor nozzles, and aircraft brake discs.

Carbon Fiber Reinforced Metal Matrix Composite Materials

Carbon fiber reinforced metal matrix composite material is a composite material with carbon fiber as reinforcing fiber and metal parts as matrix. Compared with metal materials, carbon fiber reinforced metal matrix composite materials have high specific strength and specific modulus; compared with ceramics, they have high toughness and impact resistance. The metal substrates mostly use aluminum, magnesium, nickel, titanium and their alloys. Among them, the preparation technology of carbon fiber reinforced aluminum and magnesium composite materials is relatively mature. The main technical difficulty in manufacturing carbon fiber reinforced metal matrix composite materials is the surface coating of the carbon fiber to prevent damage to the carbon fiber during the composite process, thereby reducing the overall performance of the composite material. Currently, when preparing carbon fiber reinforced metal matrix composite materials, the surface of the carbon fiber Modification mainly uses vapor deposition, liquid sodium method, etc. However, due to its complex cnc machining process and high cost, it limits the promotion and application of carbon fiber reinforced metal matrix composites.

Carbon Fiber Reinforced Cement-Based Composite Materials

Carbon fiber is added to the cement matrix to form carbon fiber reinforced cement composites (Carbon Fiber Reinforced Ce-ment Compoistes, referred to as CFRC), which is called fiber reinforced concrete. Incorporating high-strength carbon fiber into cement-based materials is an important measure to improve the crack resistance, impermeability, shear strength and elastic modulus of cement composite materials, control crack expansion, improve strong alkali resistance, and enhance deformation ability.

In addition, carbon fiber also has vibration damping properties, which can absorb shock waves and increase earthquake resistance and bending strength by more than ten times. What’s even more valuable is that carbon fiber is conductive. Adding it to the cement matrix gives the cement matrix intelligence, which greatly expands the application scope of concrete.

CFRC composite materials do not produce cracks on their surface when under load, and their tensile strength, flexural strength, and fracture toughness are several to ten times higher than those without reinforcement, and their impact toughness is also considerable. The length of carbon fiber used in chopped carbon fiber reinforced cement is generally 3~6nm, the diameter is 7~20μm, and the tensile strength ranges from 0.5~0.8GPa. The strength of ordinary cement is usually 11.76MPa. If 15% of carbon fiber is added by weight, the strength can reach 245MPa; if the amount of carbon fiber is 20%, the strength can be as high as 548.8MPa.

In addition, compared with ordinary concrete, CFRC has the advantages of light weight, high strength, good fluidity, strong diffusibility, and high surface quality after forming. When used as a partition wall, it is 1/2 thinner than a partition wall made of ordinary concrete. ~1/3, the weight is reduced by 1/2~1/3. CFRC has a variety of specifications. Among them, chopped carbon fiber reinforced concrete is mainly used in roofs, exterior walls, interior walls, floors, ceilings, etc.; long fiber concrete is used in load-bearing components. The components made of it are dimensionally stable and also have Antistatic, wear resistance, corrosion resistance and other properties, therefore, research on the performance of CFRC has developed rapidly in recent years.

Among the preforms currently being manufactured, there are two types of unidirectional preforms and fabric preforms. The unidirectional preformed material is obtained by unidirectionally arranging the fibrous carbon fibers impregnated with the matrix resin into a plane shape after curing. It takes advantage of the anisotropy of carbon fibers, resulting in high strength in the axial direction of the fibers. Fabric pre-formed material is to replace fiber with carbon fiber fabric. According to different uses, fabrics of various structures such as plain weave, satin weave and three-dimensional can be used, which are mainly used as materials.

CFRP is a kind of high-strength composite material, which has been favored by people. At present, it has been widely used in the field of sports and entertainment. In the future, it will give full play to its superior performance and add convenience to our lives. If you need carbon fiber composite materials, you can come to our company to order, the carbon fiber products produced by China Be-cu Prototype Material Technology Co., Ltd. are trustworthy.

Description: Carbon fiber has very good properties, especially it has high strength and elastic modulus. Such fibers, which are rarely used alone, are often impregnated or filled with resins as reinforcements for composite materials. Cutting-edge carbon fiber composite materials usually use long fibers, which are first woven into fabrics and then impregnated with resin.

ISO 9001 certified. BE-CU Prototype Offering CNC machining carbon fiber and other manufacturing services for carbon fiber marterial. Various capabilities include notching, labeling, drilling carbon fiber, grinding, laser cutting carbon fiber, finishing, plating, marking, CNC milling carbon fiber and turning carbon fiber.We stock high quality 3k carbon fiber sheet in a variety of thickness, types and finish. Its a great material used in applications where light weight and strength are needed such as drones. Unlike other workshops, we have no min order and are often filling orders with a single part. We also don’t make you pay for the full sheet and you only get charged for what is used. With a large selection of material, you should find everything you need to make your project come to life. We are also able to handle larger production runs and provide a competitive pricing. If we don’t have the material or finish you require, we are more the willing to look at bringing it in for you.

What Is Carbon Fiber?Carbon fiber is made of polyacrylonitrile (PAN) (or pitch, viscose) and other organic fibers by carbonization (removal of most elements except carbon) by pyrolysis method under inert gas at high temperature above 1,000 °C. Inorganic polymer fibers with a carbon content of more than 90%.

-

3D Printing Continuous Fibres

-

3D Printing Short Fibre Filled Wires

-

Laser Cutting Carbon Fiber Positioning Keyboard

-

Cnc Turning Industrial Copper-Aluminum Clad Carbon Fiber Machinery Parts

-

Carbon Fiber Luggage Tag Ornaments

-

Laser Cutting Carbon Fiber Guitar Shape Crafts

-

Laser Cutting Carbon Fiber Drone Rack

-

Cnc Milling Carbon Fiber Finger Buckle