Alumina ceramics can also be called electronic ceramics, wear-resistant ceramics and lighting ceramics. If classified according to the details, it can be generally divided into talc porcelain, 75 porcelain, 95 porcelain, 96 porcelain, 99 porcelain, etc.

At the same time, alumina ceramics can also be used to make ceramic substrates, substrates, ceramic rings, alumina ceramic rods, wear-resistant ceramics, etc. Valve plates, etc., it is precisely because of the wide application of alumina ceramics that it has certain advantages over ordinary ceramics.

The Difference Between Alumina Ceramics And Ordinary Ceramics

Next, the editor will give you a detailed introduction: Compared with metals, Be-Cu ceramic advanced ceramics have high hardness, high strength, high temperature resistance (fire resistance), special damage, corrosion resistance, acid and alkali resistance, oxidation resistance, insulation, no It has excellent properties such as magnetic properties and good chemical stability, so it is often used in environments where metal materials are not competent.

The company has advanced ceramic molding, sintering, cnc machining one-stop equipment and technology.

Hope To Have Extensive And Sincere Cooperation With Customers At Home And Abroad

- Alumina ceramics: can be divided into 95 zirconium porcelain, 99 zirconium porcelain; this can be made into alumina ceramic cutting tools, as well as all components in the engine, aerospace applications, etc. These are made of alumina ceramics of.

- Wear-resistant ceramics: It can be mainly used in mining enterprises, fan industry, power plants, thermal power plants and other industries. Wear-resistant patches, wear-resistant bricks, wear-resistant rods, etc. are used in these industries. The company can also organize construction and technical guidance. and development.

- Insulating ceramics mainly include: insulators, insulating porcelain bottles, insulating shells, insulating rods, and other products and accessories used in high and low voltage, AC and DC operations.

- Alumina ceramics have the advantages of high hardness, good wear resistance, high toughness, low friction coefficient and good corrosion resistance, so alumina ceramics are widely used in mechanical seals, cutting tools, ball milling media, Ceramic bearings, automotive engine parts, etc. The wear resistance of alumina ceramics is ten times that of alumina ceramics, and the friction coefficient of alumina ceramics is very low.

As for the difference between alumina ceramics and ordinary ceramics, I will share with you here. Compared with ordinary ceramics, it is more brittle, but its wear resistance is not high. The rapid prototyping service life of ordinary ceramics is also very short. The alumina ceramic produced just solves these shortcomings. It has good toughness, high wear resistance and long service life. It is a good choice for us. Welcome everyone to visit, inspect, our after-sales team will serve you online 24 hours a day.

About China Advanced Ceramic CNC Machining Company - Be-Cu

Manufacturer of precision machined components. Ceramic cnc machining components include high dielectric strength, electrical & corrosion resistance, & non-porous & non-shrinking properties.Manufacturer of high temperature fabricated and machinable ceramics including alumina, glass-ceramic, alumino-silicate, boron nitride and zirconium phosphate. Adhesives, coatings and potting compounds to 3200 degrees F,Air firing services for ceramics up to 1650 degrees C also available. Products include insulators, guides, washers, tubes, blocks, & rods for thermal, electrical, corrosion exposure, structural, wear, & semi-conductor operations. Services include machining to tolerances of +/- .0001, ultrasonic core drilling, centerless grinding, milling, & ID & OD threading.Surface grinding, dicing, OD (outer dia.) grinding, ID (inner dia.) grinding, centerless grinding, hole drilling, jig grinding, lapping, honing & polishing service are also available. Diamond grinding with dimensional tolerances of 5 microns & surface finishes of 0.2 microns (8 micro-in.) can be performed.Blanket orders and AutoCAD files & other 3d files accepted.Contact us for your machining ceramic project!

-

Metal Plating ZrO2 Zirconia Ceramic Parts

-

ZrO2 Structural Ceramic Semiconductor Parts

-

Alumina Ceramic Screw Type Parts

-

Cnc Machining Alumina Ceramic Screw Heating Pipe

-

Brushed Fishing Tackle Alumina Ceramic Accessories

-

Winding Machine Alumina Ceramic Wire Wheel

-

Insulation Device Microcrystalline Ceramic Multi-Slot Ceramic Column

-

99 Alumina Ceramic Spool Insulator Sleeve

-

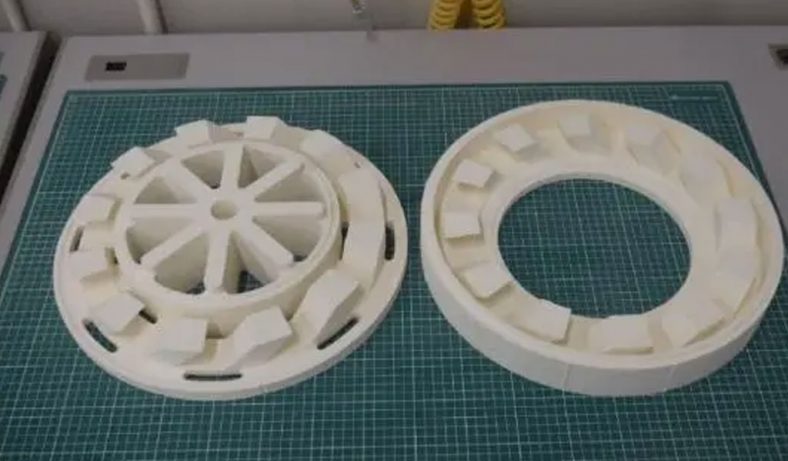

The Alumina Ceramic Ring Of Textile Machine Thread Passing Wheel

-

Isostatic Pressure Insulation Alumina Ceramic Column