What Is Carbide

Carbides are compounds composed of carbon and one or more metallic elements. They are typically very hard and have a wide range of industrial applications due to their unique properties. The most well-known example is cemented carbide, also known as tungsten carbide, which consists of tungsten and carbon atoms and is often used in cutting tools, mining equipment, and wear-resistant parts.They find applications in various industries, including manufacturing, mining, aerospace, electronics, and more. The properties of carbides make them suitable for cutting, drilling, machining, and shaping tough materials, as well as for withstanding high temperatures and harsh environments.

The Type Of Cemented Carbide

Carbides consist of carbon bonded to an element with lower electronegativity, often a metal or metalloid. This elemental combination results in compounds with diverse characteristics, depending on the specific element involved. The carbon atoms can form various types of chemical bonds, leading to a wide range of carbide structures.Carbides can be categorized into different types based on their composition and structure:

- Ionic Carbides: These carbides are formed by the reaction of metals with carbon at high temperatures. Examples include calcium carbide (CaC2) and aluminum carbide (Al4C3).

- Covalent Carbides: These carbides are characterized by strong covalent bonds between carbon atoms and the metal atoms. Silicon carbide (SiC) is a prominent example of a covalent carbide and is used in abrasive materials, refractories, and electronic applications.

- Interstitial Carbides: These carbides are formed when carbon atoms occupy the interstitial sites in a metal’s crystal lattice. Tungsten carbide (WC) and titanium carbide (TiC) are common interstitial carbides known for their hardness and wear resistance.

- Transition Metal Carbides: These carbides are often formed by transition metals like titanium, tungsten, and chromium. They have high melting points and are used in applications requiring extreme heat and wear resistance.

Metal Carbides

Metal carbides are perhaps the most well-known and extensively studied class of carbides. These can be further categorized into:

- Binary Metal Carbides: These carbides are composed of a metal and carbon. Tungsten carbide (WC) and titanium carbide (TiC) are prominent examples, celebrated for their exceptional hardness and wear resistance.

- Intermetallic Carbides: These complex carbides result from the combination of two or more metals with carbon. They often exhibit unique properties that can be tailored for specific applications.

Non-Metal Carbides

Non-metal carbides involve carbon combined with non-metal elements like boron, silicon, or aluminum. Boron carbide (B4C) stands out due to its exceptional hardness and low density, making it suitable for armor and ballistic applications.

From their intriguing chemical structure to their myriad applications spanning industries, carbides have etched their place in modern technology and innovation. The unique combination of carbon and other elements yields compounds with exceptional properties, shaping the landscape of materials science, engineering, and manufacturing.

Properties of Carbides

Carbides are valued for their hardness, high melting points, thermal stability, and chemical resistance.Some key physics and chemistry properties include:

| Carbide Type | Crystal Structure | Hardness | Melting Point | Thermal Conductivity | Electrical Conductivity |

|---|---|---|---|---|---|

| Tungsten Carbide | Hexagonal | Very High | 2780°C | 80-110 W/m·K | Insulator |

| Titanium Carbide | Cubic | High | 3140°C | 17.7 W/m·K | Insulator |

| Silicon Carbide | Hexagonal | Very High | 2700°C | 120-490 W/m·K | Semiconductor |

| Boron Carbide | Rhombohedral | Very High | 2763°C | 30 W/m·K | Semiconductor/Insulator |

| Chromium Carbide | Hexagonal | High | 1890-1975°C | 4.9-10 W/m·K | Insulator |

| Calcium Carbide | Cubic | Low to Med | 2160°C | 200 W/m·K | Semiconductor |

What Is Carbide Machining

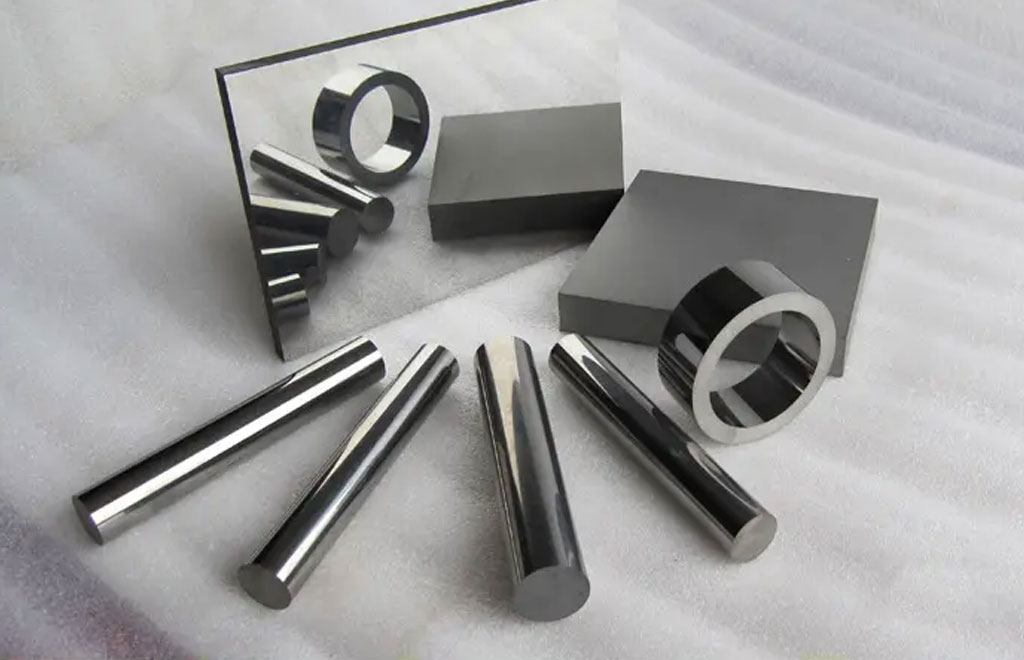

Precision machining of carbide parts is a specialized manufacturing process that involves the creation of intricately designed components using carbide materials. Carbide, composed of tungsten carbide (WC) particles bonded within a cobalt matrix, offers exceptional hardness, wear resistance, and thermal stability. This unique combination of properties makes carbide a sought-after choice for crafting components that demand tight tolerances, intricate geometries, and superior performance in challenging environments.

Cemented Carbide Machining Service – CNC Tungsten Carbide Machining

As a leader in the field of precision engineering, we have embarked on a journey to redefine the standards of machining excellence through our state-of-the-art facilities, skilled workforce, and unwavering commitment to innovation.

In today’s fast-paced and dynamic industrial landscape, precision and efficiency are paramount. As industries evolve, the demand for components that meet the highest standards of accuracy and reliability continues to surge. Our carbide machining services have been meticulously developed to address these evolving needs, offering you a seamless experience from concept to completion.

At Be-Cu prototype , we recognize that the foundation of exceptional machining lies in the expertise of our team. Our engineers and machinists boast decades of experience, complemented by a passion for innovation. This synergy allows us to take on projects that push the boundaries of what is possible, ensuring that we consistently deliver results that exceed expectations.

Our commitment to excellence is underscored by our investment in cutting-edge technology and equipment. Our facilities are equipped with the latest CNC machines, EDM systems, grinding equipment, and quality control tools. These resources empower us to take on complex projects and deliver consistent, reliable results with every engagement.

Whether you are machining this carbide alloy from block or tube, or Forming and Stamping or manufacturing powder metallurgy mold, we can heat-treat components to optimize the physical properties based on the application. We utilize cutting-edge CNC milling equipment, including 5-axis milling, and a wide range of advanced technology software to create custom components based on your specific requirements.As an industry AS9100 and ISO9001:2015 certified machine shop, we can ensure you will receive the high-performance carbide alloy components you want with the mission-critical configurations you need.Contact a Be-Cu CNC expert or submit an RFQ online and let us start machining carbide alloy to your specifications.

Be-cu works with customers all over the world to bring customers ideas to life with the highest quality precision engineered carbide alloy components on the planet. We have both precision 5 axis machining and molds making capabilities that include both conventional and modernized production line. If you are looking for a partnership to help you apply new tools and technologies, or help you fully realize your design vision, let us help you move your business forward, contact our team ([email protected])or quote online today to get the conversation started.

Carbide Machining Capabilities

With years of machining mission-critical tungsten components, Be-Cu has accumulated the knowledge and expertise needed to reliably produce high-quality tungsten alloy machined parts. Throughout our tenure as a precision CNC machining shop, we have developed a reliable, cost-effective tungsten material manufacturing steps to ensure our customers receive the best possible value.

Carbide Turning

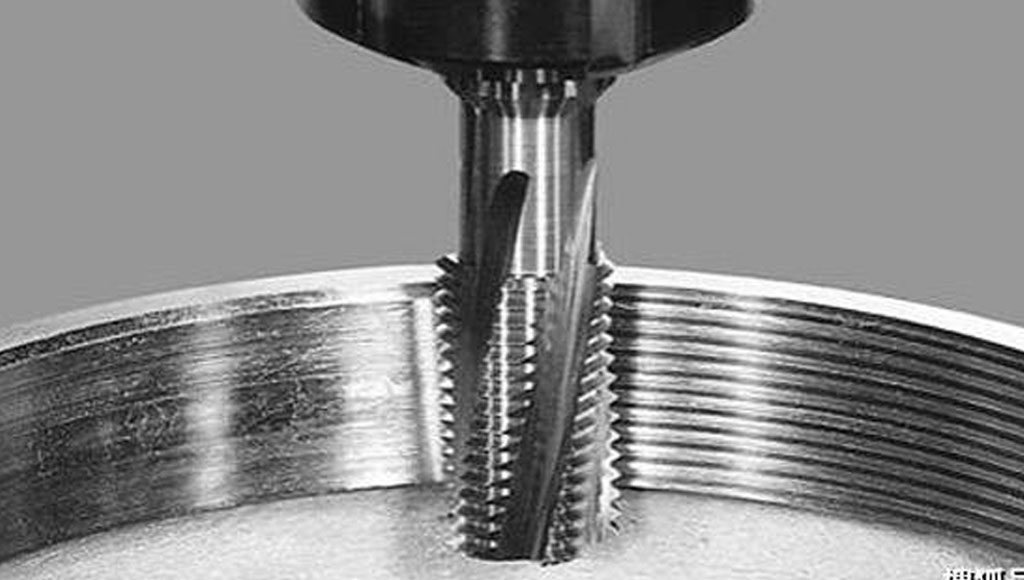

Carbide turning is a fundamental machining process that involves the use of carbide cutting tools to shape and contour a rotating workpiece.

Leveraging the exceptional hardness, wear resistance, and heat stability of carbide materials, this technique allows for accurate and efficient material removal. Carbide turning is a cornerstone of modern manufacturing, serving industries such as aerospace, automotive, and general engineering.

Carbide Milling

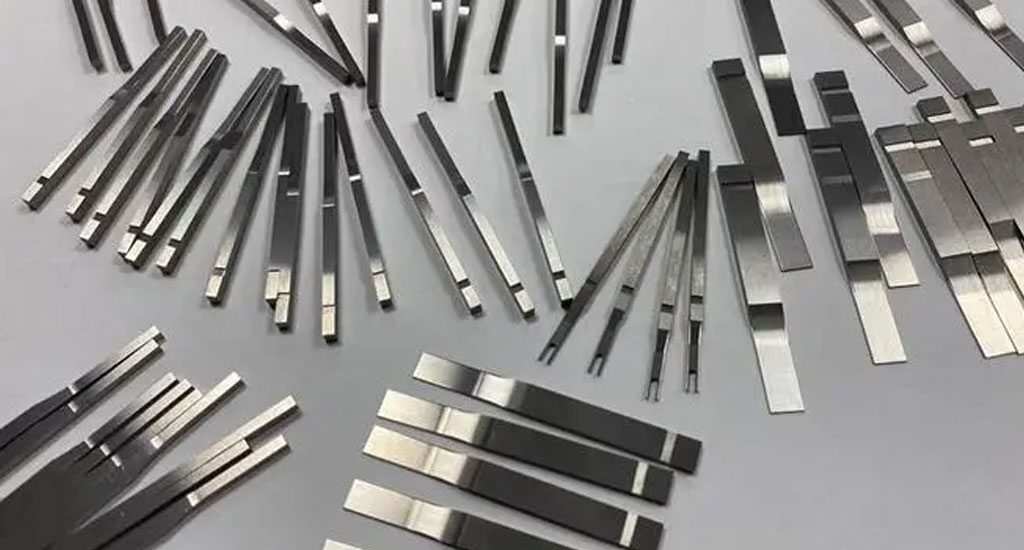

Carbide milling is a high-precision machining process that involves using carbide cutting tools to remove material from a workpiece, resulting in the creation of intricate shapes, contours, and surfaces.

The use of carbide, a composite material comprising tungsten carbide particles bound in a cobalt matrix, empowers this process with exceptional hardness, wear resistance, and heat stability. Carbide milling has become an essential technique in modern manufacturing, contributing to industries ranging from aerospace to electronics.

Electrical Discharge Machining

Grinding

Powder Sintering

Drilling Carbide

Why Choose Our Carbide Machining Service?

- Save time and money for your carbide project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of carbide grades and alloy materials can be machined

- Custom complex carbide machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top China Tungsten Carbide Machining Parts & Case Studies

Manufacturing processes such as cnc milling, turning and powder metallurgy mold are today considered the most economic way to make carbide parts. Sometimes, however, certain non-machiningable materials are needed, and sometimes sintering is the only option. Our company has rich experience making carbide concept models and precise functional components. Understanding the properties of different carbide alloy, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on magnesium alloy. Be-cu prototyping company provides a range of solutions for the machining tungsten carbide parts.