Cnc Machining Tellurium Copper C14500

Tellurium Copper C14500 is a copper alloy that contains a small addition of tellurium (Te) as an alloying element. It is also known as tellurium-bearing copper or tellurium bronze.Tellurium acts as a free-machining element in copper, enhancing the alloy’s machinability. It helps in the formation of finely divided chips during machining, reduces tool wear, and improves surface finish.The presence of tellurium contributes to increased strength and hardness compared to pure copper.

It offers better mechanical properties, making Tellurium Copper C14500 suitable for applications requiring higher strength levels.While the addition of tellurium slightly reduces the electrical conductivity of copper, Tellurium Copper C14500 still retains excellent electrical conductivity relative to many other materials.

It is often used in applications where both electrical conductivity and improved machinability are required.Tellurium Copper C14500 exhibits good resistance to corrosion, making it suitable for various environments. However, its corrosion resistance may be lower than that of pure copper. It offers a balance of machinability, strength, and electrical conductivity, making it a versatile choice for various engineering applications.

Make Machined Tellurium Copper C14500 With Be-cu

Tellurium copper C14500 has good machinability due to the addition of tellurium, which acts as a free-machining element. It promotes the formation of finely divided chips, reduces tool wear, and improves the machinability of the alloy. Tellurium copper C14500 can generally be machined at higher speeds compared to pure copper due to its improved machinability.

When working with non-ferrous metals like Tellurium Copper C14500, you need a CNC machining manufacturer that can handle more cut forces.Be-cu.com has machined tellurium copper parts for over 20 years. Be-cu workshop’s machine is similar to what you find on higher cost milling centers and leaves you almost without limits.You can design and order your parts with our free CAD software or upload your own CAD file for a fast quote.Built much heavier than the average CNC router, the industrial drive technology of a

With the correct tooling, Be-cu Tellurium Copper machining service can tackle many of your non-ferrous material needs with ease. Whether you are working with Tellurium Copper parts,tube or block, Be-cu has the options necessary to perform your one-off, production, and nested manufacturing jobs.You can contact us by requesting a quote for any Tellurium Copper C14500 manufacturing process. One of our project managers will review your application and get a quote and DFM feedback for you within 12 business hours.

Why Choose Our Tellurium Copper C145 Cnc Machining Service?

- Save time and money for your tellurium copper C145 project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of copper grades and alloy materials can be machined

- Custom complex copper cnc machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

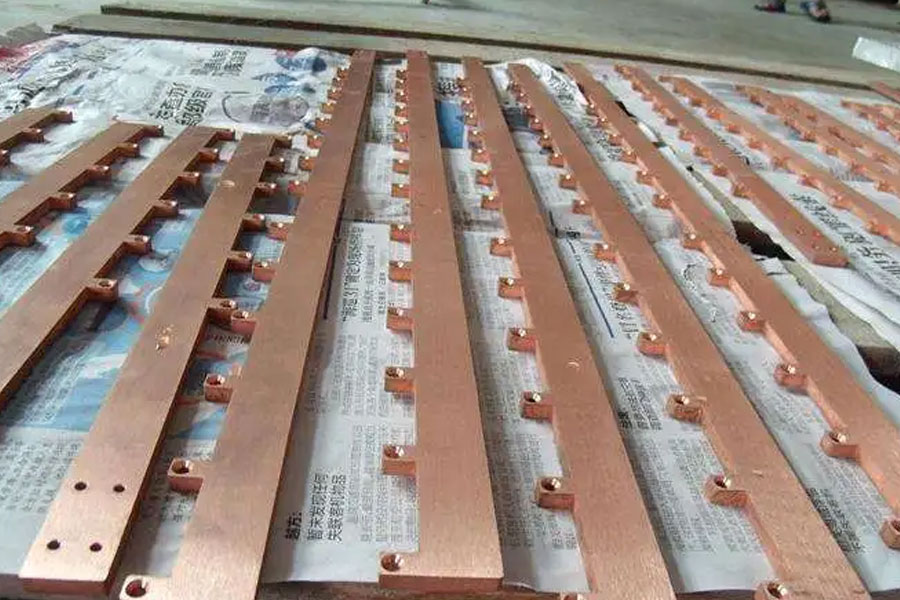

Top Tellurium Copper C145 Machined Parts & Case Studies

Cnc Machining processes such as cnc milling, turning and swiss machining are today considered the most economic way to make tellurium copper c14500 prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes sheet metal manufacturing is the only option. Our company has rich experience making tellurium copper c14500 concept models and precise functional components. Understanding the properties of different copper alloy, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on copper alloy. Be-cu prototyping company provides a range of solutions for the machining of copper parts.

-

CNC Turning-Milling Machining Copper Facial Massage Roller

-

Precision Wire Cutting Plastic Injection Mould Core

-

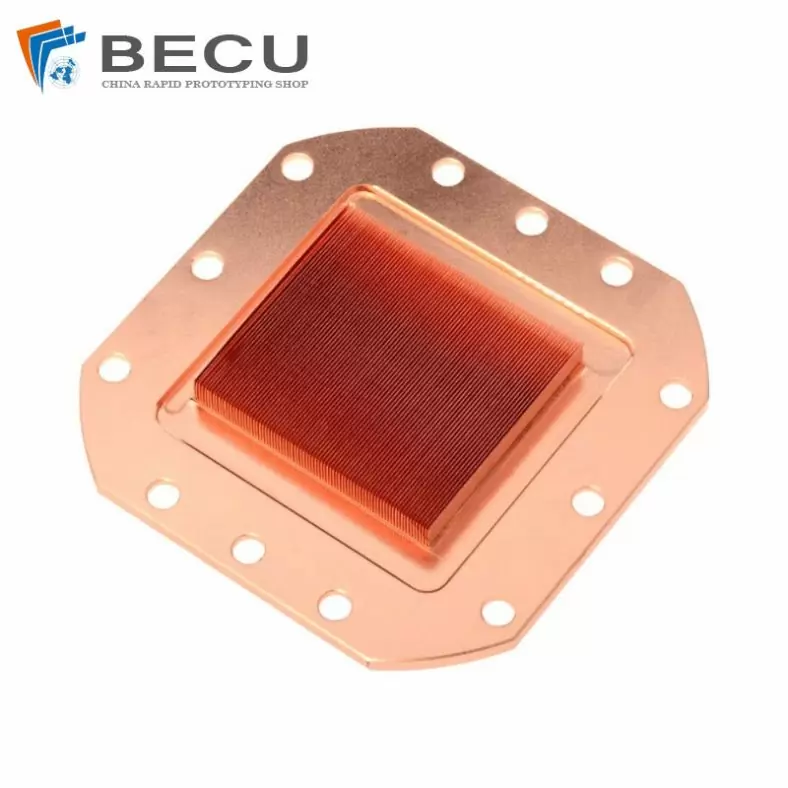

Custom Machining Copper Water Cooling Heat Sink

-

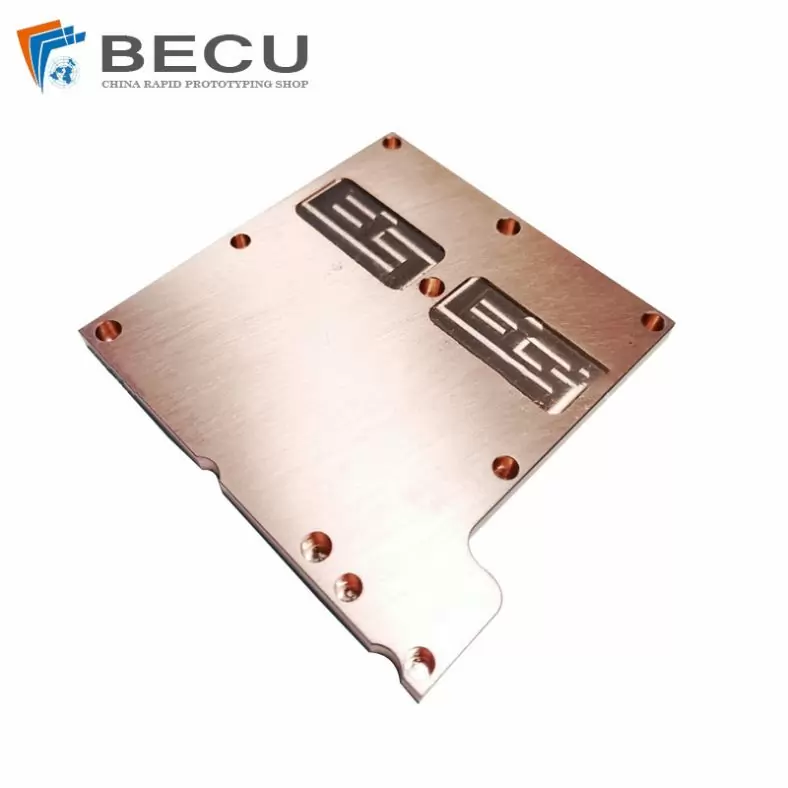

Cnc Carved Machining And Wire Cutting Copper Electrode

-

CNC Milling Automotive Audio Amplifier Base

-

Precision Machining Heatsink Spacer Substrate

-

Precision Turning T3 Copper Machinery Parts By Polishing

-

Precision Milling Machining Chrome-Plated Copper Spare Parts

-

Precision CNC Turning N9 Copper Parts

-

Swiss Turning Gold-Plated T2 Copper Parts

-

Precision Machined Copper Die Casting Parts

-

CNC Turning New Energy Vehicle Copper Connector

The Chemical Composition Of Tellurium Copper C145

Tellurium-bearing copper or tellurium bronze, typically includes the following elements:

- Copper (Cu): Approximately 99.5% minimum

- Tellurium (Te): Typically 0.4% to 0.7%

- Other Impurities: Including small amounts of phosphorus (P), sulfur (S), and traces of other elements

The addition of tellurium to copper in Tellurium Copper C14500 enhances its machinability while providing improved strength and hardness compared to pure copper. The small amounts of impurities present in the alloy have a minor influence on its mechanical and electrical properties.

Mechanical Properties Of Tellurium Copper C145

Below are typical mechanical properties for annealed Tellurium Copper C14500:

- Tensile Strength: 290 MPa (42,000 psi) minimum

- Yield Strength: 170 MPa (25,000 psi) minimum

- Elongation: 12% minimum

- Hardness: 80 HRB (Rockwell B) minimum

These values represent the general mechanical properties for annealed Tellurium Copper C14500. It is important to note that these properties can change with different temper conditions such as half-hard, hard-drawn, or fully annealed copper.

Tellurium Copper C14500 offers improved strength and hardness compared to pure copper due to the presence of tellurium. Additionally, the alloy retains good electrical conductivity relative to many other materials, making it suitable for applications that require both electrical conductivity and improved machinability.

It’s worth mentioning that the mechanical properties of Tellurium Copper C14500 can be further modified through processes such as cold working, annealing, or heat treatment. These processes can affect properties such as strength, hardness, and elongation, allowing for tailored mechanical properties to suit specific applications.

Heat Treatment Process Of Tellurium Copper C145

Here are two common heat treatment processes used for Tellurium Copper C14500:

- Annealing: Annealing of Tellurium Copper C14500 can be performed to relieve internal stresses, improve ductility, and enhance the machinability of the material. Annealing is typically carried out by heating the material to a specific temperature range, typically between 450°C and 700°C (840°F to 1300°F), and then slowly cooling it to room temperature. The exact temperature and time parameters may vary depending on the specific requirements and recommendations of the material specification or manufacturer.

- Stress Relief: Stress relief heat treatment can be applied to reduce residual stresses that may have developed during manufacturing processes such as cold working or machining. This process involves heating the material to a temperature below its recrystallization temperature (around 200°C to 300°C or 390°F to 570°F) and holding it at that temperature for a specific period, followed by slow cooling. Stress relief can help minimize distortion or dimensional changes in the material.

Online Cooperate With Tellurium Copper Machining Company

Be-cu works with customers all over the world to bring customers ideas to life with the highest quality precision engineered metal components on the planet. We have both precision cnc machining and molds making capabilities that include both conventional and modernized production line. If you are looking for a partnership to help you apply new tools and technologies, or help you fully realize your design vision, let us help you move your business forward, contact our team ([email protected])or quote online today to get the conversation started.