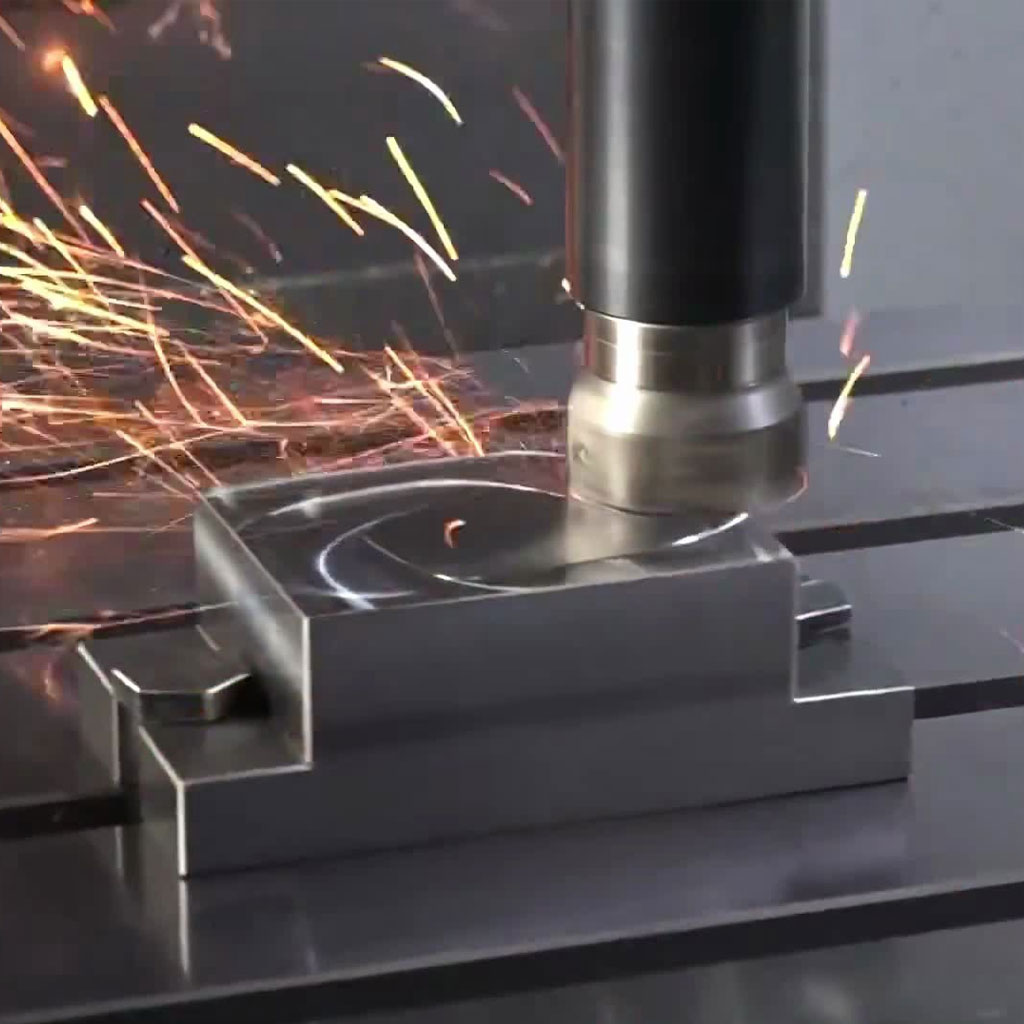

Cnc Machining 17-4 PH Stainless Steel

CNC machining 17-4 PH stainless steel involves using Computer Numerical Control (CNC) equipment to cut, shape, and produce parts or components from this specific type of stainless steel. 17-4 PH stainless steel is a precipitation-hardening martensitic stainless steel alloy known for its combination of high strength, good corrosion resistance, and ease of machining relative to some other stainless steel grades.

The Composition Of 17-4 PH Stainless Steel

- Chromium: Around 15-17.5%

- Nickel: Around 3-5%

- Copper: Around 3-5%

- Manganese: Around 1% (or less)

- Silicon: Around 1% (or less)

- Columbium/Niobium or Tantalum: Small percentages

- Carbon: Less than 0.07%

- Iron: The remaining balance

17-4 PH stainless steel is a precipitation-hardening martensitic stainless steel known for its combination of high strength, corrosion resistance, and toughness. The “PH” stands for “precipitation hardening.” Its composition typically includes the following elements:

- Iron (Fe): The base element of stainless steel, providing its structural foundation.

- Chromium (Cr): Contributes to the steel’s corrosion resistance by forming a passive oxide layer on the surface that prevents rusting and staining.

- Nickel (Ni): Enhances the material’s toughness and corrosion resistance, especially in harsh environments.

- Copper (Cu): Contributes to the alloy’s corrosion resistance and improves its strength through precipitation hardening.

- Manganese (Mn): Affects the steel’s strength and hardenability.

- Silicon (Si): Enhances the alloy’s strength and aids in deoxidization during the steelmaking process.

- Columbium (Niobium) / Tantalum (Ta): These elements can be added in small amounts to improve the steel’s weldability and formability.

- Carbon (C): The carbon content is kept low to maintain the steel’s weldability and corrosion resistance.

The Benefits Of 17-4 PH Stainless Steel CNC Machining

Machining 17-4 PH stainless steel offers several benefits due to its unique properties and characteristics. Here are some advantages of machining this particular type of stainless steel:

High Strength

Corrosion Resistance

Machinability

Versatility

Heat Treatability

Reduced Wear and Abrasion

Dimensional Stability

Weldability

Cost Efficiency

It’s important to note that while 17-4 PH stainless steel offers numerous advantages for machining, proper understanding of its properties, suitable tooling, cutting parameters, and heat treatment processes are crucial to fully leverage these benefits and achieve high-quality machined parts.

Custom 17-4 PH Parts – CNC Machining 17-4 PH Stainless Steel Service

Be-Cu prototype company is committed to meeting the Customers’ stated and implied requirements for 17-4 PH Stainless Steel cnc machining shop’s jobs.. Our key objectives are to: provide quality products, reliability, deliver on-time, increase customer satisfaction. We provide precision CNC machining 17-4 PH alloy for industries like: Medical, Biotech, Electronics, Aerospace, Automotive, Aircraft, and Semiconductor.

At Be-Cu.com, we understand the importance of stainless steel in engineering applications due to its exceptional corrosion resistance, strength, and aesthetic appeal.

We provide Turning and Milling, 3 axis , 3+2 axis & continuous 5 axis cnc machining.

We are competitive in custom rapid prototyping, precision short-run and high-volume machining projects, ensuring that we can meet the specific requirements of your project. Get started on your next CNC machining 17-4 PH stainless steel project today by uploading your part to be-cu.com for an instant quote or by contacting our team.

Industries & Applications

Stainless Steel Alloy 17-4 PH, with its unique combination of properties including high strength, corrosion resistance, and good mechanical properties, finds applications across several industries. Some notable industries and applications where 17-4 PH stainless steel is commonly used include:

- Shafts

- Seals

- Medical equipment

- Aerospace components

- Marine Parts

- Connectors

- Terminals

- Aircraft components

CNC SUS 17-4 PH Capabilities

- Swiss machining 17-4 PH Stainless Steel

- CNC milling 17-4 PH Stainless Steel

- CNC turning 17-4 PH Stainless Steel

- 5 Axis machining 17-4 PH Stainless Steel

- CNC cutting 17-4 PH Stainless Steel

- Turn-mill machining 17-4 PH Stainless Steel

- More

You can contact us by requesting a quote for any 17-4 PH Stainless Steel manufacturing process. One of our project managers will review your application and get a quote and DFM feedback for you within 12 business hours.

Why Choose Our 17-4 PH Stainless Steel Cnc Machining Service?

- Save time and money for your 17-4 PH Stainless Steel project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of stainless steel grades and alloy materials can be machined

- Custom complex stainless steel cnc machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Stainless Steel Alloy 17-4 PH Machined Parts

Cnc Machining processes such as cnc milling, turning and swiss machining are today considered the most economic way to make 17-4 PH Stainless Steel prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes laser cutting is the only option. Our company has rich experience making 316 Stainless Steel concept models and precise functional components. Understanding the properties of different copper alloy, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on stainless steel alloy. Be-cu prototyping company provides a range of solutions for the machining of Stainless Steel parts.

-

Swiss Turning 304 Stainless Steel Medical Threaded Rod

-

Swiss Machining Stainless Steel Pin Cylindrical Discharge Needle

-

Swiss Machining Stainless Steel Alloy Medical Disposable Trocar

-

Screw CNC Machining Non-Standard Mandrel Tube Shaft

-

Precision Swiss Machining Tooth Drive Screw Rod

-

Precision CNC Turning Stainless Steel Transmission Arm Parts

-

Precision Cnc Turning Stainless Steel 316 Machine Screw

-

Precision 316 Stainless Steel Cookware Boiler Cover For Kitchen

-

Custom Stainless Steel Marine Deck Screws

-

Custom Stainless Steel 316 Goblet By Turning

-

CNC Turning Stainless Steel 316 Men Spinner Rings

-

CNC Turning Stainless Steel 316 Grinding Core For Coffee Mill

Mechanical Properties Of Stainless Steel Alloy 17-4 PH

Stainless Steel Alloy 17-4 PH, also known as UNS S17400 or Type 630, is a precipitation-hardening martensitic stainless steel. Its mechanical properties make it suitable for a wide range of applications across various industries. Here are some of its key mechanical properties:

- Tensile Strength: The tensile strength of 17-4 PH stainless steel typically ranges between 100,000 psi (690 MPa) to 160,000 psi (1100 MPa), depending on the heat treatment and the specific condition of the material.

- Yield Strength: The yield strength is approximately 80,000 psi (550 MPa) to 140,000 psi (965 MPa). Similar to tensile strength, it can vary based on the heat treatment.

- Elongation: The elongation at break is generally between 10% to 15%, again depending on the specific condition and treatment.

- Hardness: 17-4 PH stainless steel achieves high levels of hardness after heat treatment. The typical hardness ranges from HRC 30 to HRC 45, depending on the heat treatment conditions.

- Impact Strength: It exhibits good impact resistance, especially in the hardened condition, making it suitable for applications requiring toughness.

- Corrosion Resistance: Like other stainless steels, 17-4 PH offers excellent corrosion resistance, particularly in environments where mild corrosion is a concern.

- Fatigue Resistance: It has reasonably good fatigue resistance, but this property can be influenced by factors such as the specific environment and stress levels.

- Machinability: It can be machined in the annealed condition, but its hardness after heat treatment can make machining more challenging. Proper machining techniques and tools are required for optimal results.

- Weldability: Welding of 17-4 PH stainless steel can be achieved using common welding methods, but post-weld heat treatment is often necessary to restore its full strength and corrosion resistance.

- Heat Treatment: The material can be heat-treated to achieve different mechanical properties. Common heat treatments include solution annealing, precipitation hardening, and aging to optimize the material’s strength and toughness.

It’s important to note that the mechanical properties of 17-4 PH stainless steel can vary based on the specific composition, manufacturing processes, heat treatment, and the final condition of the material. These properties make it a versatile alloy suitable for various applications in industries such as aerospace, chemical processing, marine equipment, and more.

Online Cooperate With Stainless Steel Alloy 17-4 PH Machining Company

Be-cu works with customers all over the world to bring customers ideas to life with the highest quality precision engineered metal components on the planet. We have both precision cnc machining and molds making capabilities that include both conventional and modernized production line. If you are looking for a partnership to help you apply new tools and technologies, or help you fully realize your design vision, let us help you move your business forward, contact our team ([email protected])or quote online today to get the conversation started.