What Is Beryllium Copper Etching

Beryllium copper, also known as beryllium bronze, is the “king of elasticity” among copper alloys. Through solid solution aging heat treatment, it can achieve high strength and high conductivity properties. High-strength cast beryllium bronze alloy, after heat treatment, not only has high strength and high hardness, but also has the advantages of wear resistance, corrosion resistance, and excellent castability. Beryllium bronze alloy is suitable for manufacturing various molds, explosion-proof safety tools, wear-resistant parts such as cams, gears, worm gears, bearings, etc. High-conductivity cast beryllium copper alloy, after heat treatment, has high electrical conductivity and thermal conductivity. Beryllium copper alloy is suitable for manufacturing switch components, strong contact and similar current-carrying components, electrode materials for resistance welding, clamps, plastic molds, water-electric continuous casting machine crystallizers, etc.

High beryllium copper has the characteristics of high strength, high hardness, high electrical conductivity, high elasticity, wear resistance, fatigue resistance, corrosion resistance, and small elastic hysteresis, mainly used in temperature controllers, mobile phone batteries, computers, automotive parts, micro motors, brushes, advanced bearings, glasses, contacts, gears, punches, various spark-free switches, various welding electrodes, and precision casting molds, etc.There are several methods for etching beryllium copper, including chemical etching and plasma etching. Chemical etching typically involves immersing the material in an etchant solution that selectively dissolves the exposed areas. Common etchants for beryllium copper include ferric chloride or ammonium persulfate. The etching process may take some time and may require agitation or heating, depending on the etchant used.

Beryllium Copper Etching Service – Beryllium Bronze Etching Company

In our endeavor, with over a decade of etching processing experience, we harbor a specialized etching technical team. Distinguished as one of the pioneering companies to join the PCMI Etching Industry Association, BE-CU stands adept in promptly receiving the association’s technical guidance, boasting mature processes. By importing etching production lines, we facilitate large-scale, standardized production, employing automated etching to minimize manual intervention, thereby presenting a heightened price competitiveness relative to peers. Guided by the ethos of “Devotion to Innovation, Rooted in Quality, Dedicated Service, Esteemed Clients,” we solemnly pledge to you, embracing responsibility and transparency:

Conventionally, stamping or laser techniques are employed, yet stamping struggles with burrs and oil contamination, jeopardizing precision. BE-CU’s beryllium copper etching boasts superior precision, utilizing chemical etching, emerging as the preferred domestic alternative to Taiwanese and Japanese production. Achieving minimum apertures of 0.1mm, with flatness retained under 0.02mm, and minimum tolerances of +/-0.01mm contingent on material thickness.Delivery Time: Equipped with a sample production team, we ensure completion within 2-3 working days. Our company, fortified by robust technical prowess (8 senior R&D engineers, 16 engineers, 20 technicians) and advanced production equipment (imported etching machines), guarantees punctual delivery of beryllium copper etching.

After-Sales Service: Should clients raise quality disputes concerning our beryllium copper etching, the company commits to responding within 12 hours of receipt, dispatching professional technical and quality personnel for on-site resolution if necessary. Until quality issues are rectified, service personnel will remain stationed. Each instance of customer feedback regarding etching product quality and its resolution will be meticulously archived.

All beryllium copper etchings undergo three rounds of production inspection, quality testing, and dispatch sampling by relevant personnel before shipment, ensuring that the products delivered to you are of impeccable quality.

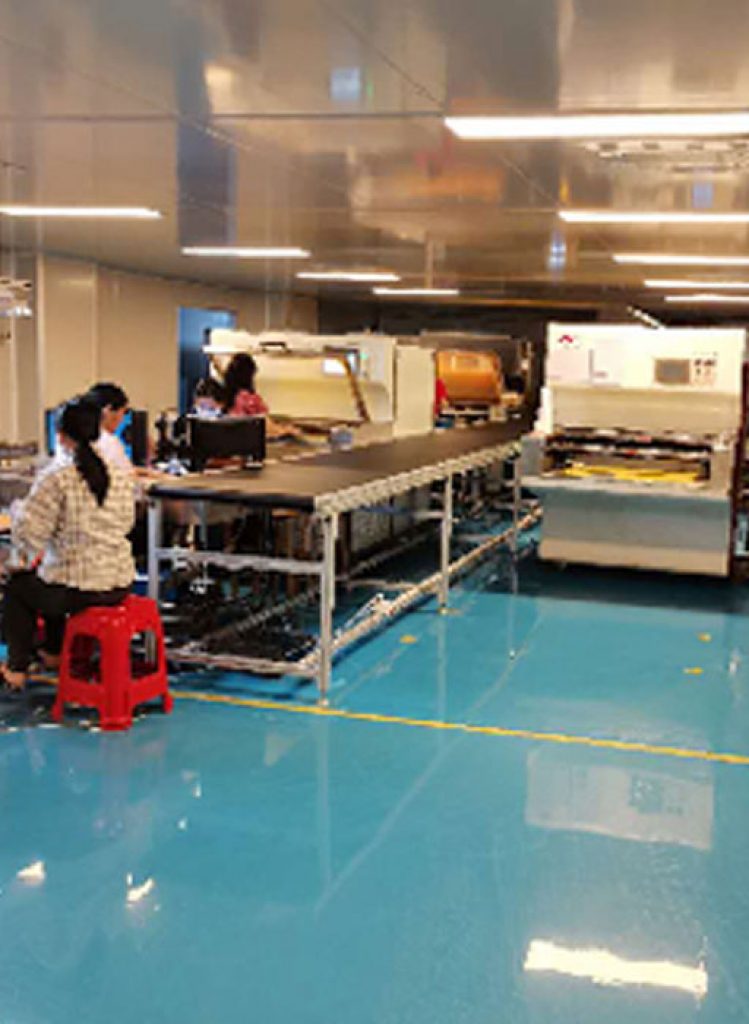

- Be-cu Prototype with 16 total automatic etching lines (10 horizontal and 6 vertical etching lines) which can deal with massive demand that request 700K piece per day as well as your individual customized small size requesting proceed by half automatic etching line.

- We have ful set of automatic production lines for cleaning, coating, development, etching and stripping etc with strong.

- Smallest line width 0.015mm, aperture 0.03mm with smallest tolerance as t 0.01mm can be fulfilled to meet your requirements

- Be-cu uses state-of-the-art digital imaging machines to precisely map designs onto the metal sheets and eliminate variations so production remains consistent – as do we.

With an ISO 9001:2015 certificated manufacturing factory, we provide material and full dimensional inspection reports as your request. You can always rest assured the parts you get from Be-cu.com will exceed your expectations.To use our online metal etching service, submit your design file for metal etching services and get instant metal etching quotes.

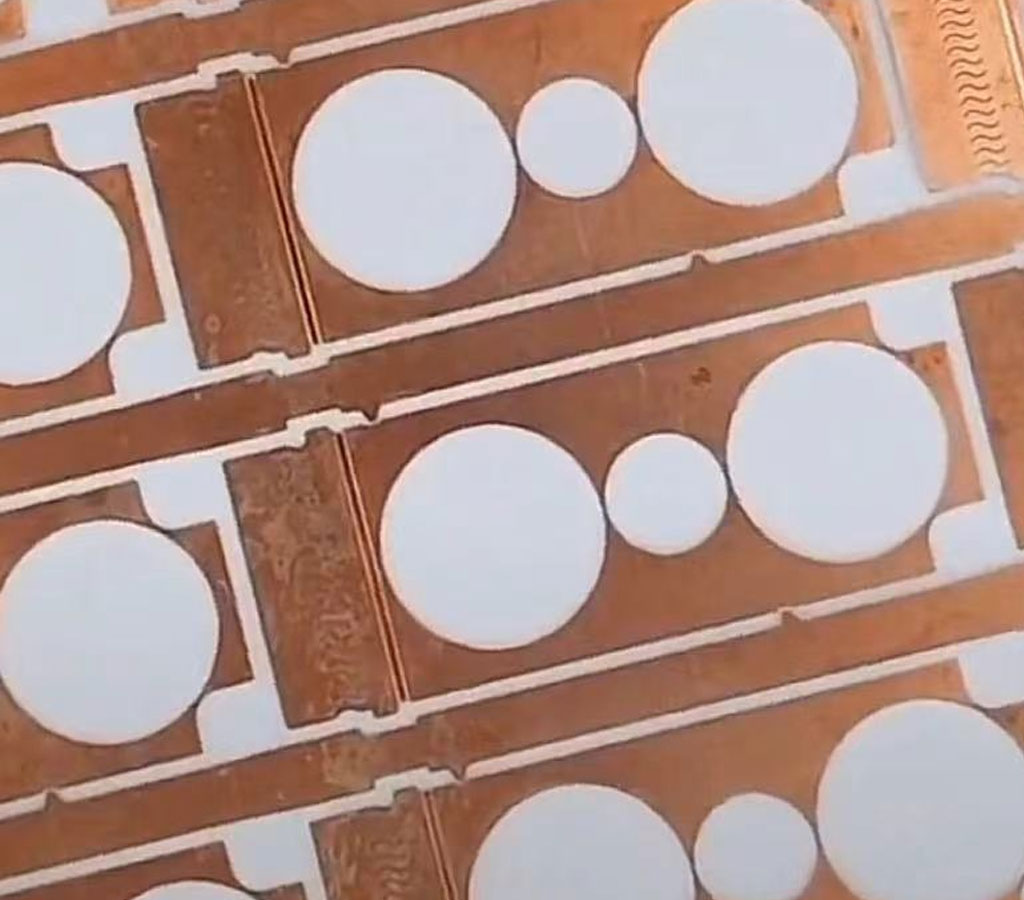

Beryllium Copper Chemical Etching Process In BE-CU Prototype

Automatic Shearing

Etching Metal

Coating For Etching Parts

Deinking

Automatic Baking Line

Automated Coating

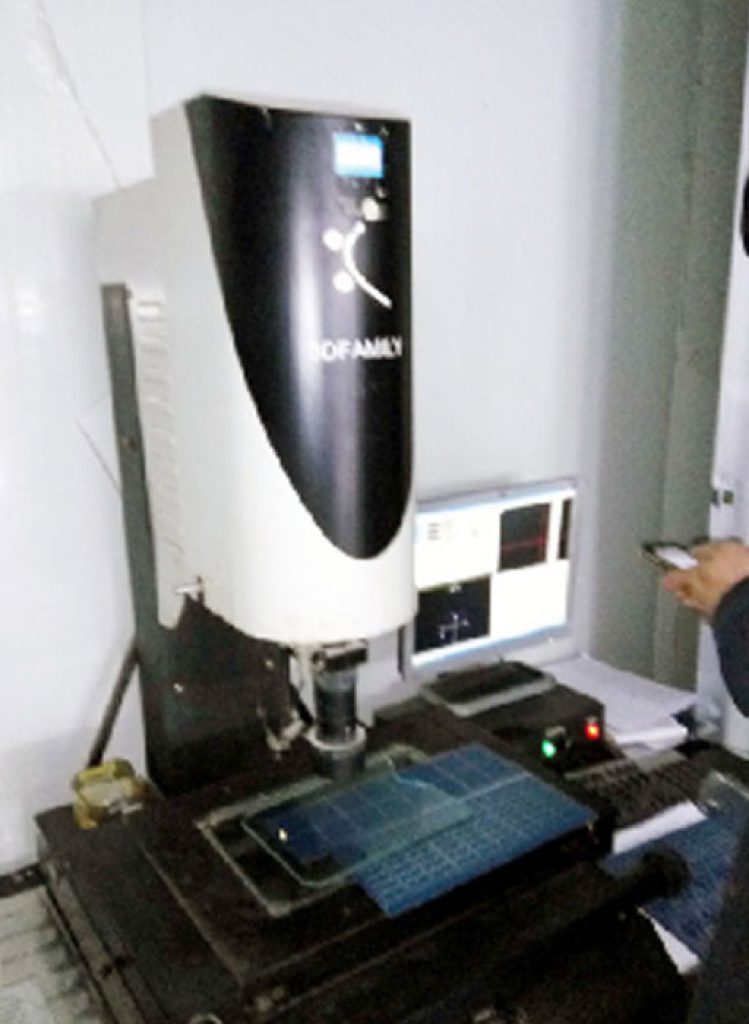

Inspection For Etching

Exposure

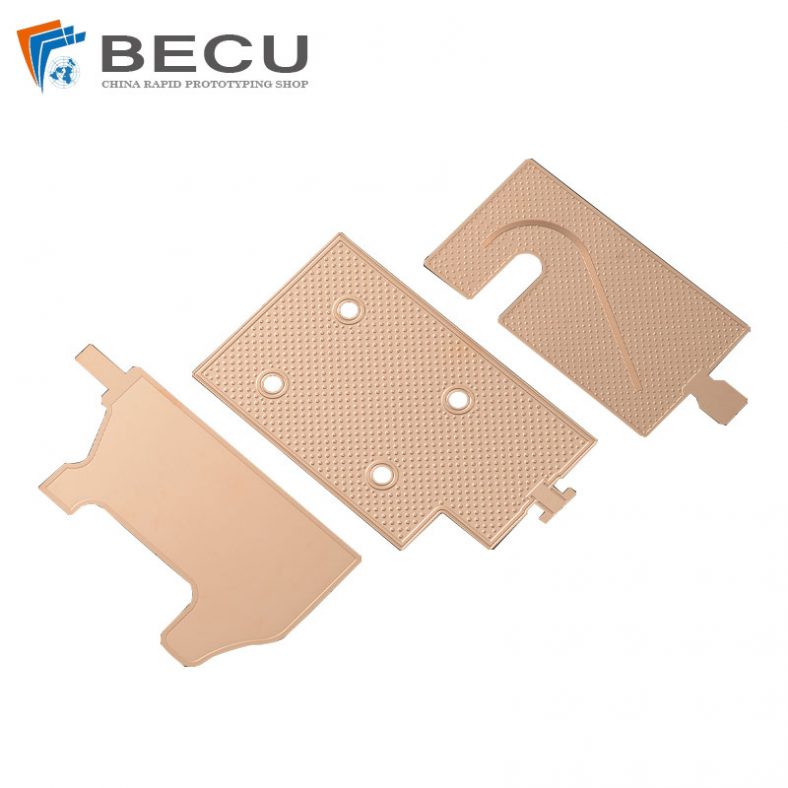

Beryllium Copper Etching Parts & Case Studies In China

As one of professional Beryllium Copper Chemical Etching manufacturers from China, Be-Cu.Com has own specialized technical staff and management team to design as your custom draws and samples, we have rich experience and understand each type of the Beryllium Copper material characteristics. So we can offer you the best etching copper solution according to your requirements of Beryllium Copper parts and products.

Surface Finishing Options for Beryllium Copper Etching

Parts made using etching usually feature excellent finishes. At Be-cu.com, we offer various custom finishing options that boost the produced part’s functionality, appearance, and durability.

- BLACKENING SERVICES

- ELECTROPOLISHING

- PAINTING

- PASSIVATING

- REAMING

- TUMBLING

- CUSTOM PACKAGING

Online Cooperate With Beryllium Copper Etching Company

Be-cu works with customers all over the world to bring customers ideas to life with the highest quality precision engineered metal components on the planet. We have both precision etching,beryllium copper machining and molds making capabilities that include both conventional and modernized production line. If you are looking for a partnership to help you apply new tools and technologies, or help you fully realize your design vision, let us help you move your business forward, contact our team ([email protected])or quote online today to get the conversation started.