Lens Eyepiece Element

- Product Name: Aluminum Parts

- No+Color:Custom

- Surface Treatment: Anodized Oxidation

- Product Material: Aluminum Alloy

- Proofing Cycle:7 days(100000 pcs/M)

- Application:Precision Cnc Machining

- Machining Factory:Be-cu Rapid Prototyping Companies

- Product Category: Optical Machining

- Production Process:Cnc Machining

- Size: According To Customer’s Drawings

High-Quality Custom Astronomical Telescope Wide-angle Lens Eyepiece Element

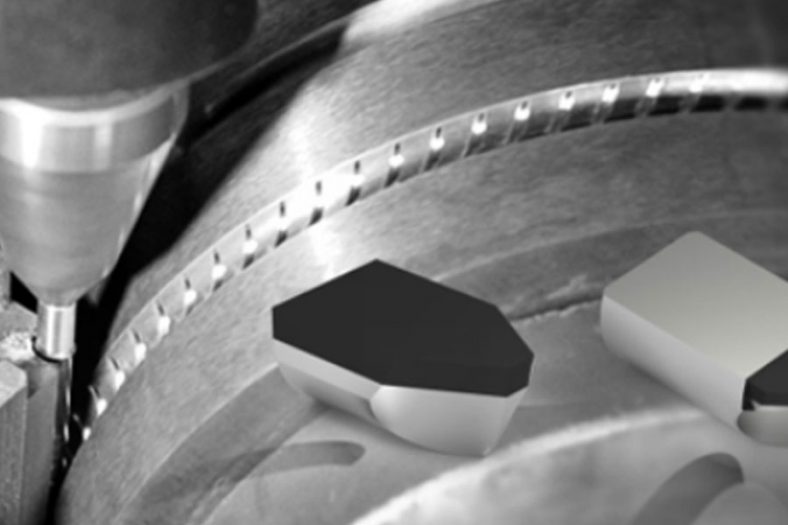

Astronomical telescope wide-angle lens eyepiece element is a specific component of an eyepiece used in astronomical telescopes. It is designed to provide a wide field of view, allowing observers to see a larger portion of the night sky or a celestial object at once.

The wide-angle lens eyepiece element typically consists of multiple lens elements arranged in a specific configuration to achieve the desired optical performance. These lens elements work together to correct for various optical aberrations and distortions, ensuring a sharp and clear image across the wide field of view.

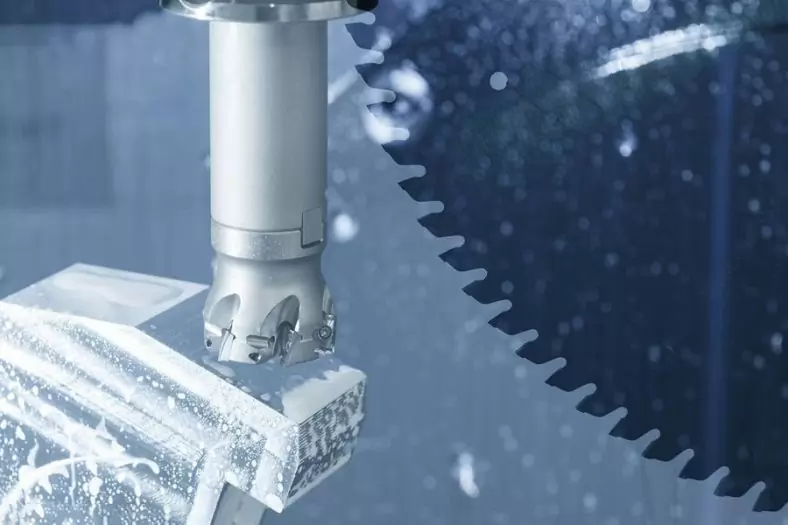

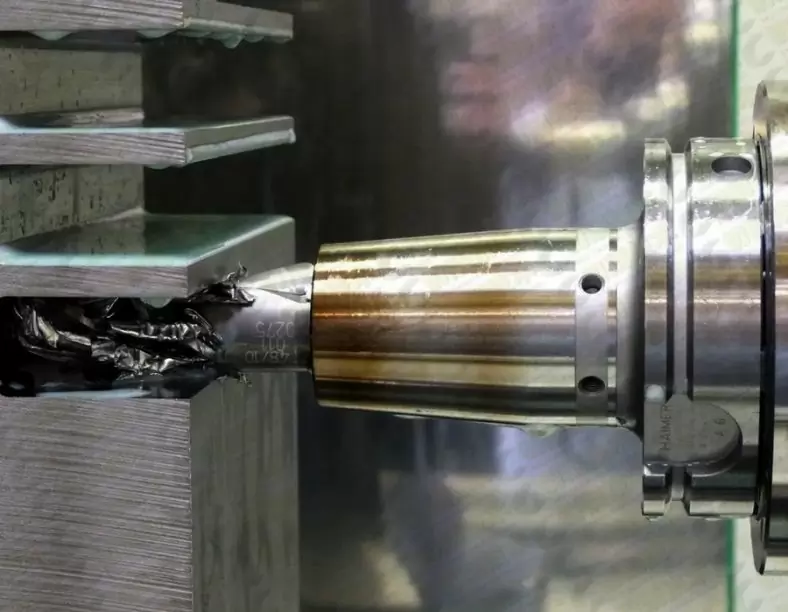

CNC machining of an astronomical telescope wide-angle lens eyepiece element refers to the process of using computer numerical control (CNC) technology to manufacture the lens element. CNC machining offers precision, repeatability, and flexibility in the production of complex optical components, including the wide-angle lens eyepiece element.

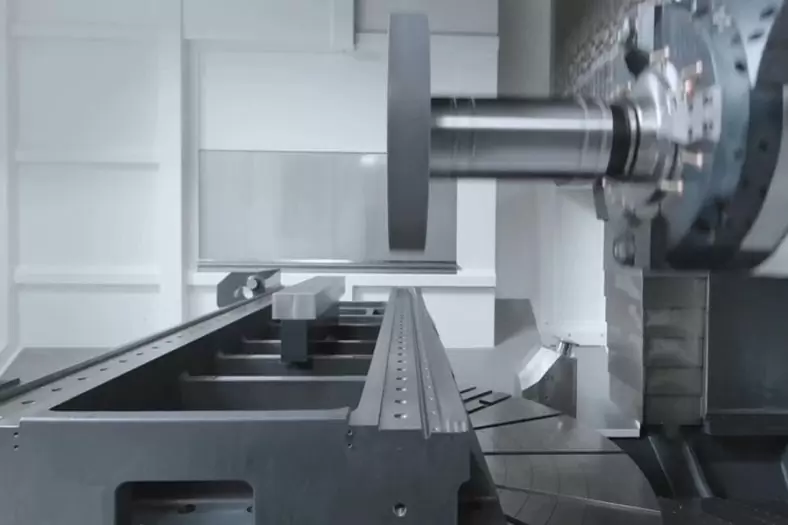

As Astronomical Telescope Wide-angle Lens Eyepiece Element CNC machining China service supplier, BE-CU prototype provides high-quality rapid prototyping and mass manufacturing services, including CNC machining, rapid tooling and injection molding, sheet metal prototyping, die casting, aluminum 3D printing, and so on. We provide manufacturing solutions that realize your design within a few hours, we have more than 70 precision CNC processing equipment of various types to ensure the best quality of products.

With a professional team of decades of experience, our company has passed the ISO9001:2008 and TS16949 quality system certification in 2015 and obtained the IATF quality system transition audit certification in 2017. Get your quote in hours, parts delivered in days.

The Advantages Of Custom Astronomical Telescope Wide-angle Lens Eyepiece Element

- – Excellent wear and impact resistance

- – Durable and solid, long lifetime

- – Good strength and electrical conductivity

- – Customization based on customer specification

Specifications of Custom Cnc Milling Astronomical Telescope Wide-angle Lens Eyepiece Element

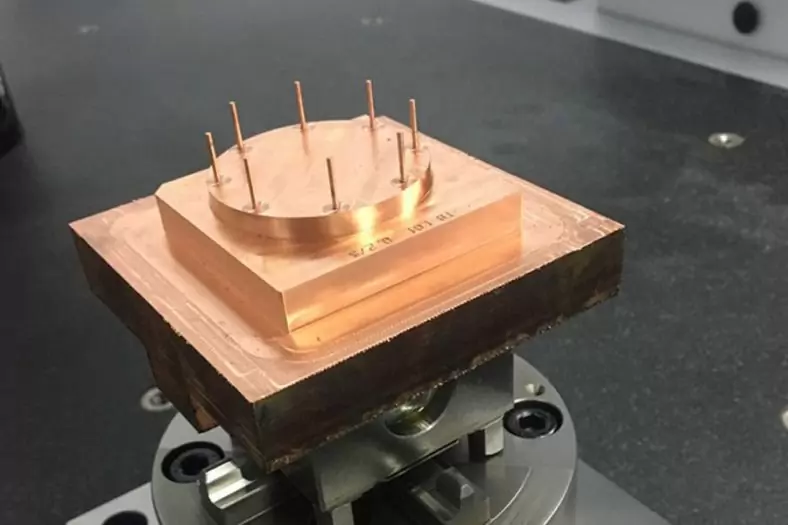

| Material | Aluminum 2024 Machining |

| Tolerance | +/-0.05mm |

| Surface Treatment | Custom |

| Main Process | Milling, drilling, 5 axis cnc machining |

| Quality Control | Strictly Quality control in the whole process, from material to packing, Coordinate-measuring machine |

| Usage | Automotive,Motorcycle |

| Customized Drawings | Auto CAD, JPEG, PDF, STP, IGS, and most other file formats are accepted |

The Detail Of BE-CU Cnc Milling Company

Looking for low cost CNC milling parts with unparalleled quality? BE-CU Prototype is a professional China CNC company provides superior precision CNC milling service with advanced machines including CMC milling center and milling machining centers from the general 3-axis to 5-axis and accomplished machinists. Our experienced operators proficient in CAD (computer-aided design) and CAM (computer-aided manufacturing) programs are always finding the best way to produce the highest quality CNC milled parts & components for clients. With strong capabilities and extensive experiences, we can provide top-grade but cost-effective custom CNC milling services from China including 3-axis CNC milling and 5-axis milling for high-speed CNC manufacturing, rapid prototyping, and precision CNC milling and turning. Our high-quality rapid CNC milling products are involved in the field of automation design, lockset, automobile parts machining, machinery milling, defense industry, medical equipment, lighting parts machining, etc.