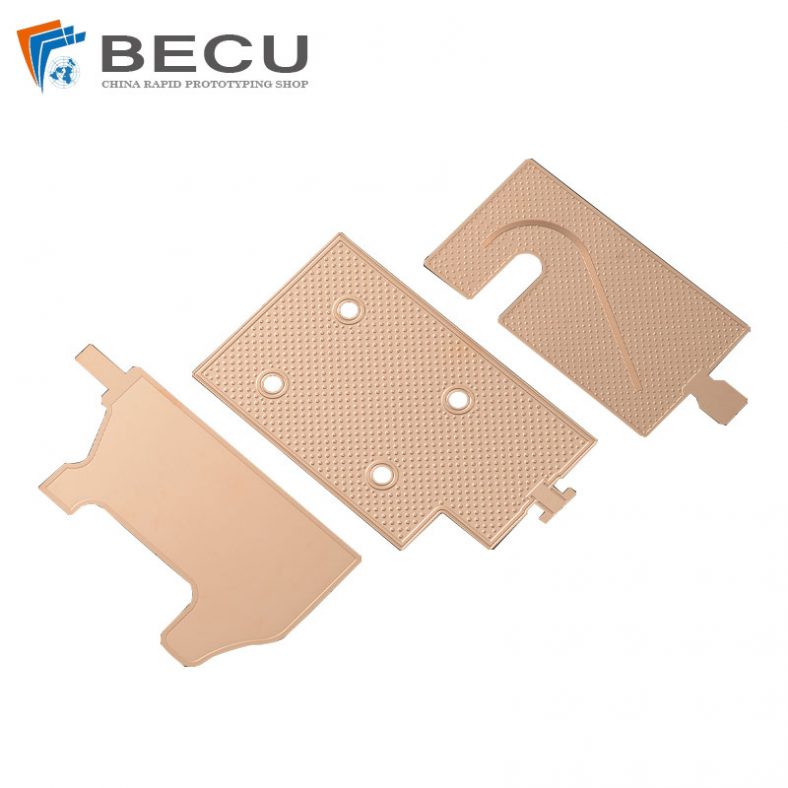

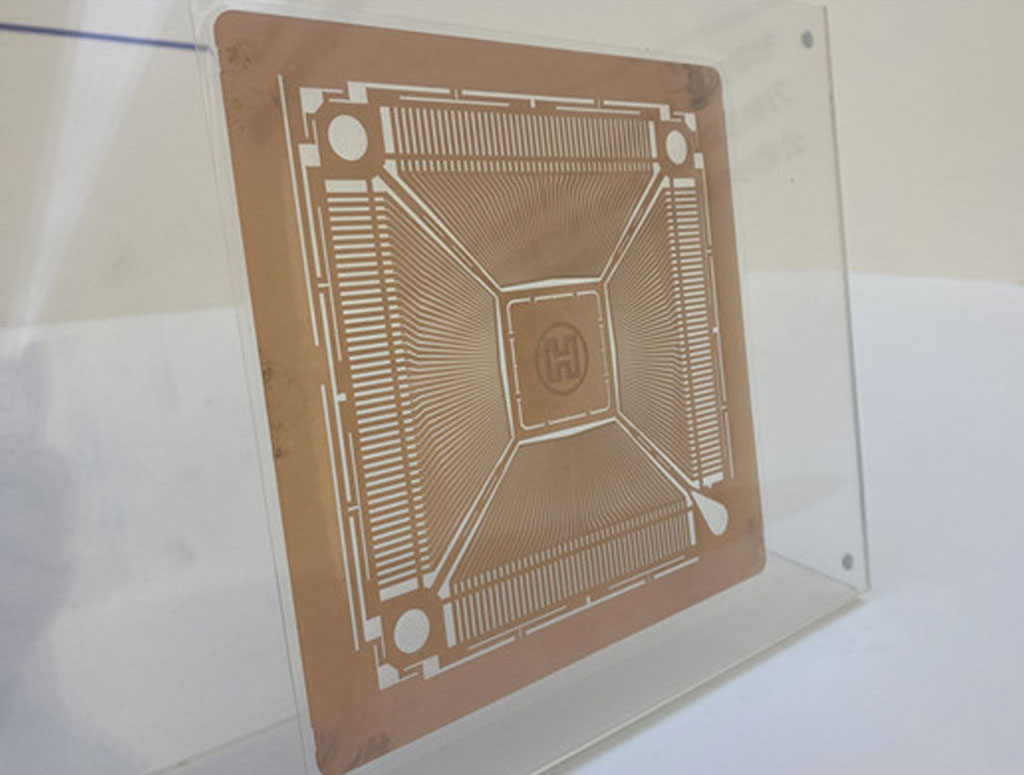

The types of copper etching materials include phosphor copper, oxygen-free copper, nickel nickel, brass, red copper, bronze plating, etc.Be-cu etching has rich copper etching experience and professional copper passivation production line, which can handle the copper etching process very well Problems encountered in the process, such as oxidation, water stains, scratches, etc., provide customers with copper etching post-process services including stamping, surface passivation treatment, etc.

What Is Copper Etching

Copper etching is a selective removal process used to create images on copper plates. Most etching processes require a metal plate covered with a non-reactive material, which is then selectively removed.

Copper panels are exposed to corrosive substances that remove small amounts of copper without affecting the protected area. In the past, this was done with waxes and different acids. Modern copper etching typically uses less toxic materials such as ferric chloride to remove it rather than acids and sodium carbonate. Modern etching techniques are used in everything from artistic expression to printing inks to laying paths on circuit boards. The most common industrial use of copper etching is in the fabrication of circuit boards.

A design or drawing printed from an etched surface may also be called an etching. The name is derived from the Dutch word etch, “to erode” or “to eat”. Etching differs from the similar process engraving in that the engraved lines are made with sharp tools rather than an acid reaction.

Etching is usually done on polished copper or zinc, but steel, iron or glass can also be used. Etching is both an art form and a commercial process. Only the art form is discussed here. For commercial etchings see entry printing, subtitle letterpress and intaglio printing.

Copper Etching Service – Copper Chemical Etching Company

Copper Etching parts are suitable for many different applications today. Yet, quality Copper Etching services are pivotal to meeting the design specification and requirements for these copper parts.

At Be-cu.com, we have experienced professionals that can handle all your copper precision etching services. We boast top-notch etched line and cutting copper techniques to meet your specific product design.

Contact us today for one-on-one support service, and you will get a response within 12 hours.

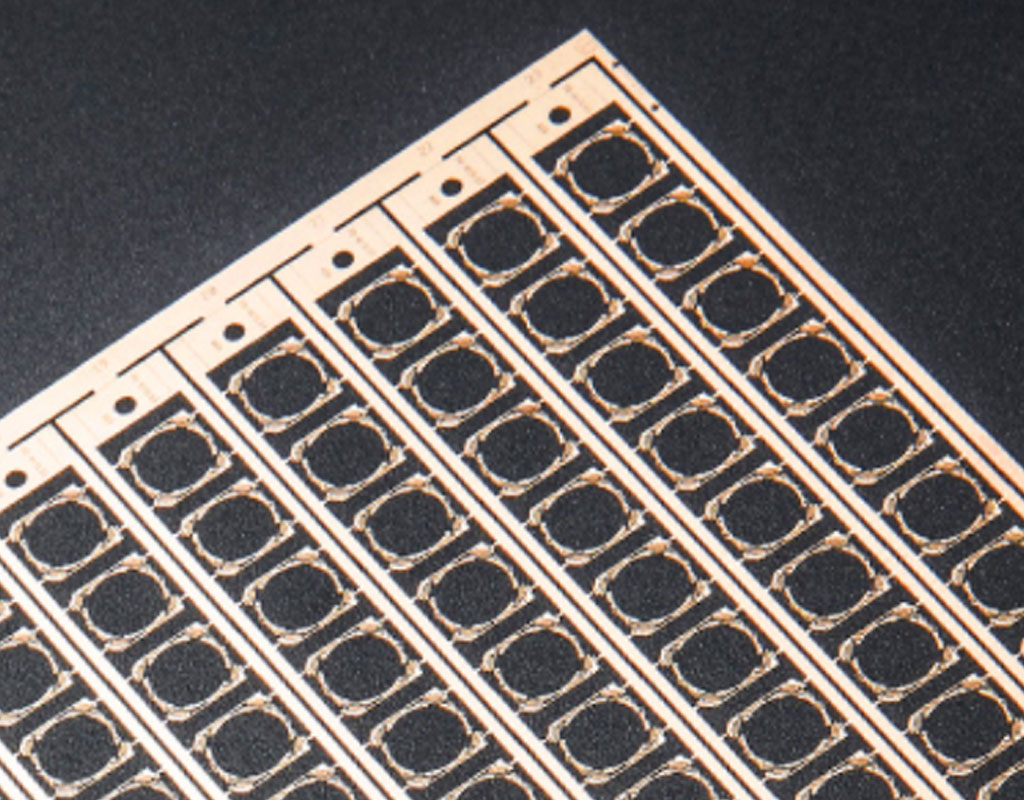

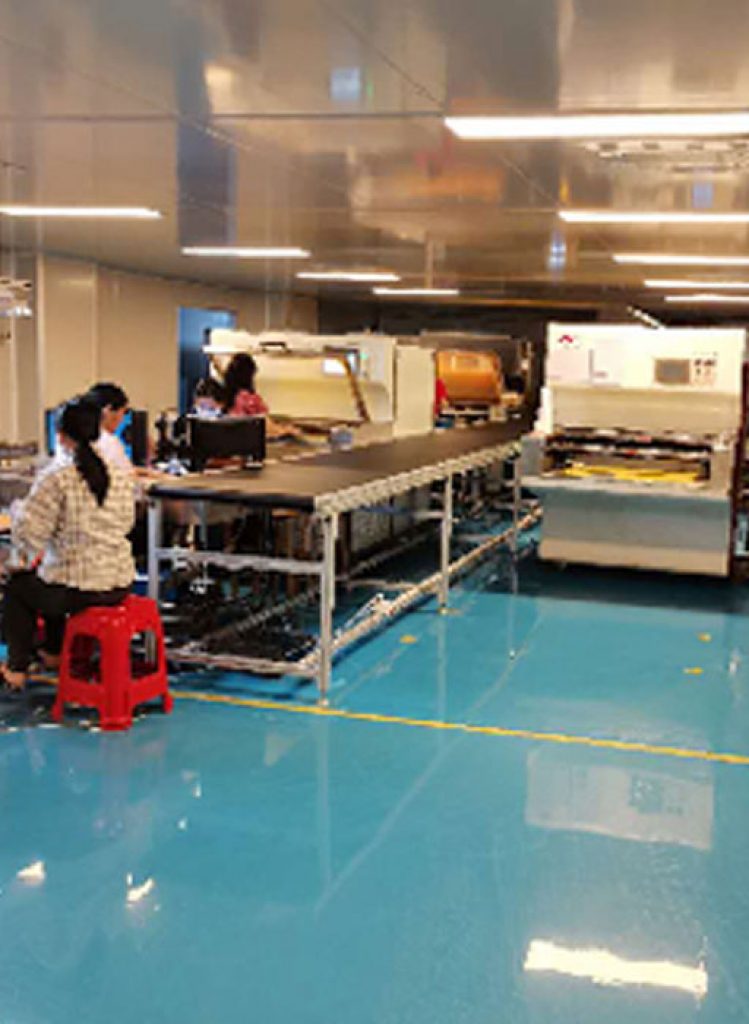

- Be-cu Prototype with 16 total automatic etching lines (10 horizontal and 6 vertical etching lines) which can deal with massive demand that request 700K piece per day as well as your individual customized small size requesting proceed by half automatic etching line.

- We have ful set of automatic production lines for cleaning, coating, development, etching and stripping etc with strong.

- Smallest line width 0.015mm, aperture 0.03mm with smallest tolerance as t 0.01mm can be fulfilled to meet your requirements

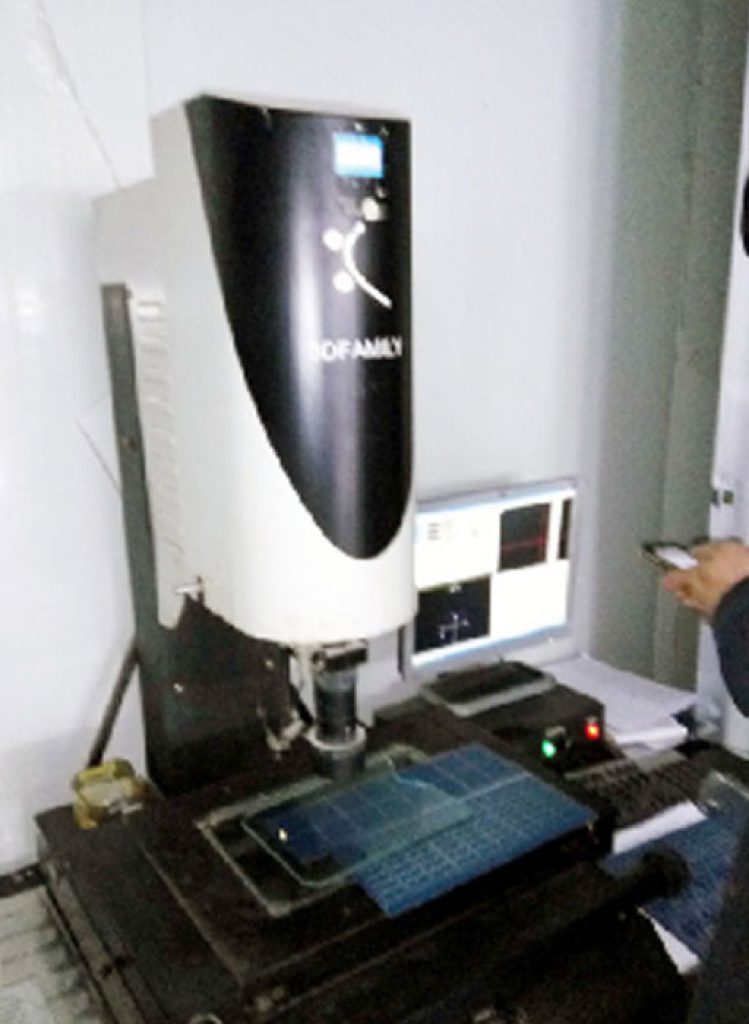

- Be-cu uses state-of-the-art digital imaging machines to precisely map designs onto the metal sheets and eliminate variations so production remains consistent – as do we.

With an ISO 9001:2015 certificated manufacturing factory, we provide material and full dimensional inspection reports as your request. You can always rest assured the parts you get from Be-cu.com will exceed your expectations.To use our online metal etching service, submit your design file for metal etching services and get instant metal etching quotes.

Copper Chemical Etching Process In BE-CU Prototype

Automatic Shearing

Etching Metal

Coating For Etching Parts

Deinking

Automatic Baking Line

Automated Coating

Inspection For Etching

Exposure

Copper Chemical Etching Parts & Case Studies In China

As one of professional Copper Chemical Etching manufacturers from China, Be-Cu.Com has own specialized technical staff and management team to design as your custom draws and samples, we have rich experience and understand each type of the Copper material characteristics. So we can offer you the best etching Copper solution according to your requirements of Copper parts and products.

Surface Finishing Options for Copper Chemical Etching

Parts made using photo etching usually feature excellent finishes. At Be-cu.com, we offer various custom finishing options that boost the produced part’s functionality, appearance, and durability.

- BLACKENING SERVICES

- ELECTROPOLISHING

- PAINTING

- PASSIVATING

- REAMING

- TUMBLING

- CUSTOM PACKAGING

Chemically Etched Copper

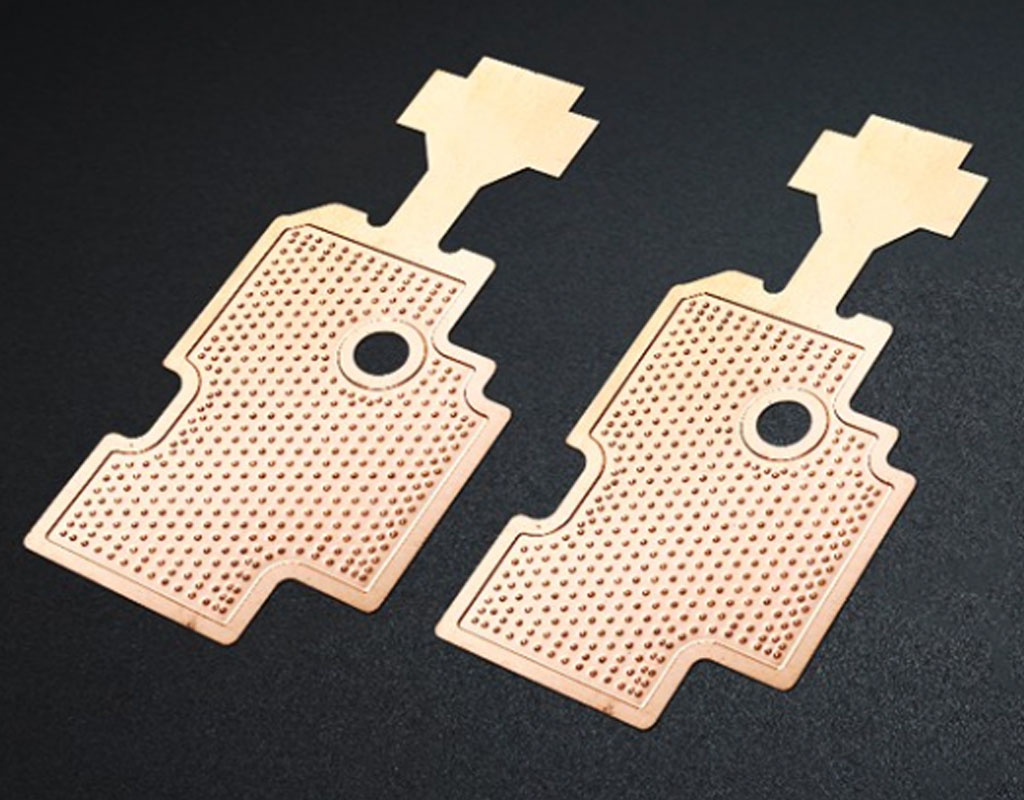

Chemically etched copper components are used in electronic systems across many industries. Copper has excellent electrical and thermal conductivity, which will improve the component’s ability to handle high voltages and currents.

We have been etching copper components for EMS and OEM companies for decades. Copper is softer than other metals, etches easily, and provides precise results. Although it is highly corrosion resistant, flashing the base plate with nickel and/or adding silver plating will further increase its corrosion resistance. Additionally, adding tin plating to etched parts will increase high temperature resistance and improve solderability.

Copper alloys, such as phosphor bronze, beryllium copper, brass, and nickel silver, have most of the functional properties of copper, but with additional elements that improve strength, electrical conductivity, and corrosion resistance.

The copper and copper alloy properties listed below will help you choose the right metal for your project. With our copper etch experience, we can help you choose the most functional and cost-effective type for your application.

The Properties Of Copper

- Toughness – Bends easily if secondary forming operations are required

- Conductivity – Good thermal and electrical conductivity

- Corrosion Resistant – Especially on nickel and silver backplanes

- Non-Magnetic – Helps protect against EMI emissions

- Solderability – Can be soldered without adding plating

- Plasticity – Can be squashed or stretched

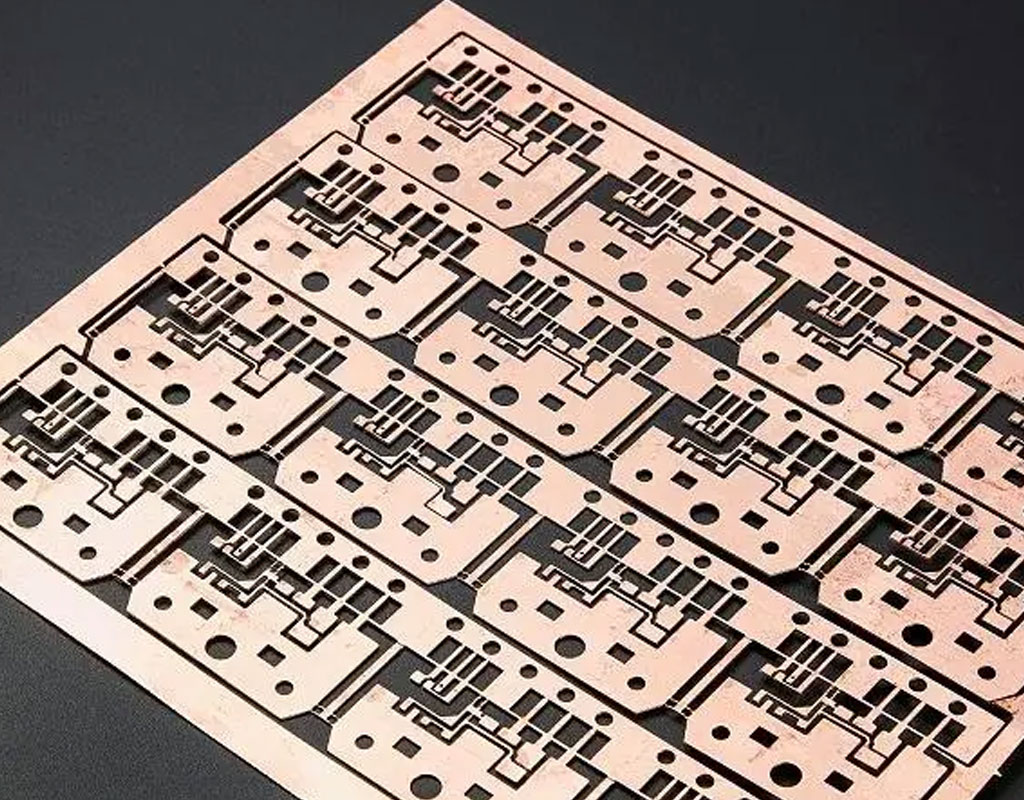

The Benefits Of Photoetching Copper

Since copper is a softer metal, certain sheet metal fabrication processes may affect the structure of the part. For example, punching holes during stamping can cause deformation, especially if the holes are small and/or numerous. Lithography excels in precision and maintaining low dimensional tolerances without burrs and distortion.

Wire EDM is suitable for conductive metals such as copper and copper alloys, and works well with smaller and thinner parts, although there is a possibility of thermal damage. Laser cutting is challenging because copper absorbs infrared laser light poorly.

Chemical etching is proven to be the most accurate and cost-effective method for microelectronics and RF microwave products. At the same time, the manufacturing method is fast, and the pickling makes the surface and edges of the parts clean and smooth.

The advantages of photochemical etching of copper over other types of metal fabrication processes are as follows:

- Low Cost Molds – Molds can be produced quickly at a fraction of the cost of traditional hard molds. Prototype modifications are cheap.

- No Burrs And Stress – Parts are etched evenly and quickly without any contact points.

- Metallic Properties Remain The Same – Properties of copper remain the same as there is no heat-affected zone

- Low Cost Complex Designs – Copper parts with small holes, slits, slots, or other complex features cost less than other manufacturing processes when larger runs are required.

The Application Of Copper Etching

- Copper Etching Electronics and RF/Microwave Components

- Contact pads Lead frames RF waveguides

- Pin Flat Spring Spacer

- Connector Busbar Gasket

- EMI/RFI Shield Grounding Clamp Mesh

- Step cover Antenna Screen

Online Cooperate With Copper Photo Etching Company

Be-cu works with customers all over the world to bring customers ideas to life with the highest quality precision engineered metal components on the planet. We have both precision etching and molds making capabilities that include both conventional and modernized production line. If you are looking for a partnership to help you apply new tools and technologies, or help you fully realize your design vision, let us help you move your business forward, contact our team ([email protected])or quote online today to get the conversation started.