What Is Nanofabrication And Nano Manufacuring Technologies

In the realm of manufacturing, the adage “small is the new big” couldn’t be more pertinent. Micro nanofabrication and nano manufacturing, once the domain of niche applications, are now at the forefront of technological innovation, promising to revolutionize industries ranging from electronics and healthcare to aerospace and beyond.

Micro manufacturing involves the fabrication of miniature components with dimensions typically ranging from a few micrometers to a few millimeters. It encompasses various processes such as micro-machining, micro-forming, micro-injection molding, and micro-additive manufacturing (3D printing).

Nano manufacturing, on the other hand, operates at an even smaller scale, dealing with structures and devices on the nanometer level (1-100 nanometers). It utilizes techniques like nanolithography, molecular self-assembly, and nanoimprint lithography to create incredibly precise and intricate structures.BE-CU nano tech co ltd offers effective nanomanufacturing services that can enhance production capabilities and lower costs in your manufacturing operation. As a leading metal nanofabrcation innovator since 1995, you can count on us to develop a customized micro nano manufacturing methodology that meets your specific operational requirements.

Top Nanofabrication Manufacturer – China Micro Nano Fabrication co ltd

Microfabricated drug delivery systems, such as microneedles and nanostructured carriers;From semiconductor fabrication to the production of MEMS (Micro-Electro-Mechanical Systems) devices and flexible electronics;Enabling the production of lightweight yet robust materials, advanced sensors, and high-performance components;Injection molds and fuel injectors for the Automotive industry. Waveguides, beam channels and sensor components for the Scientific industry.

These are just a small sample of all the types of components that BE-CU Nanomanufacturing Solutions has manufactured. There really aren’t many types of parts that BE-CU has not worked on in some form over the last 30 years serving these industries. No project is too big or part too complex or tolerance too tight for BE-CU Nanomanufacturing Solutions which makes us the preferred partner for OEM manufacturers globalwide.

Advantages Of Nanofabrication

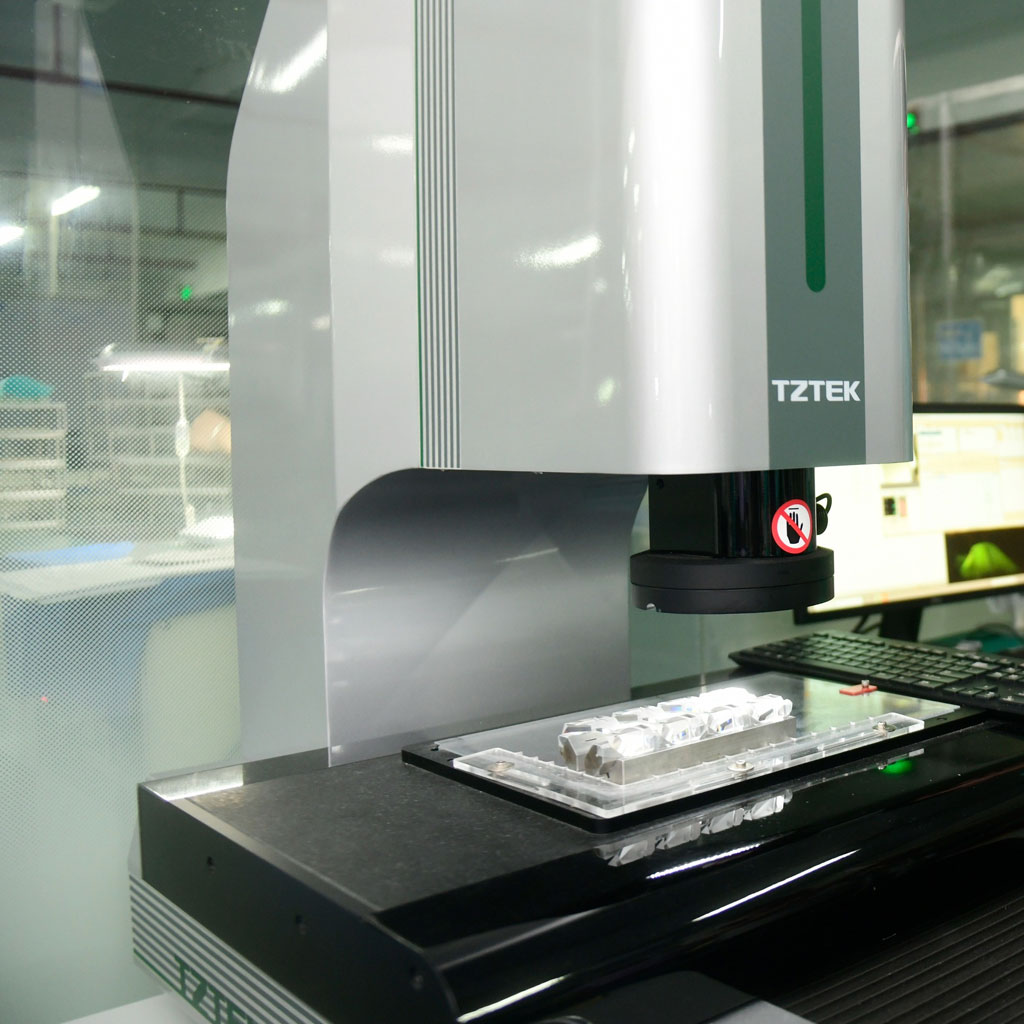

Ultra-precision machining technology is one of the important indicators to measure the advanced manufacturing level of a country, serving as the foundation and key of advanced nanofabrication technology.In the guidance system gyroscopes of the 02MX strategic missile (capable of carrying 10 nuclear warheads), if the mass center of the gyro rotor deviates from its axis of symmetry by 0.5 nanometers, it will result in a range error of 100 meters and an orbit error of 50 meters.

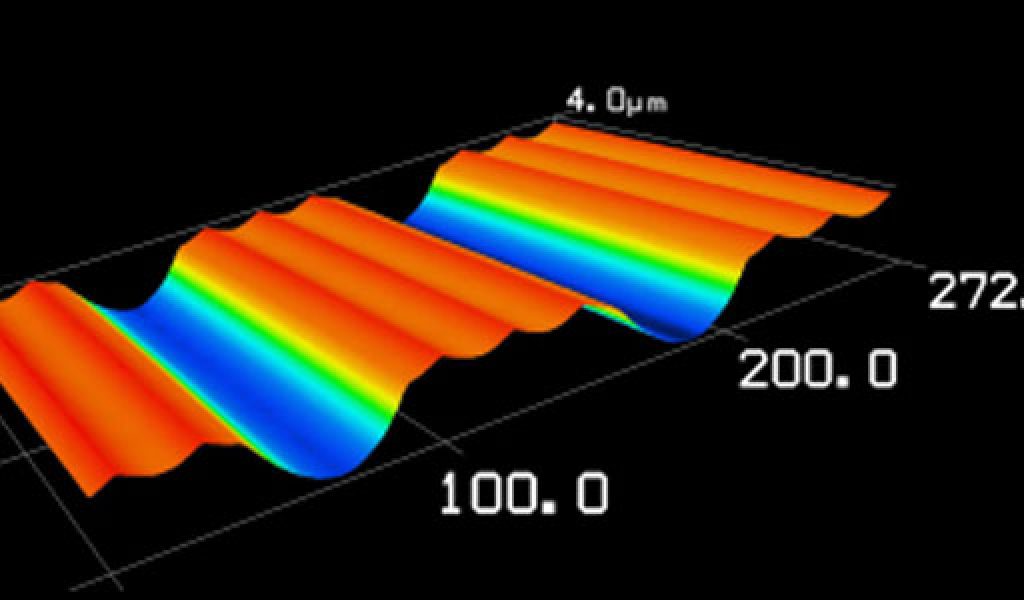

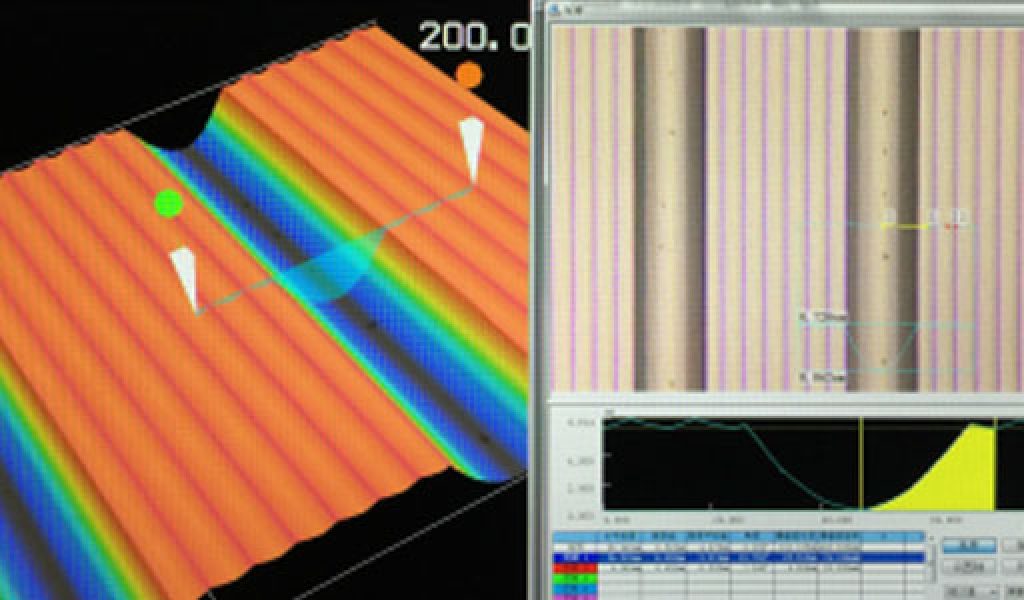

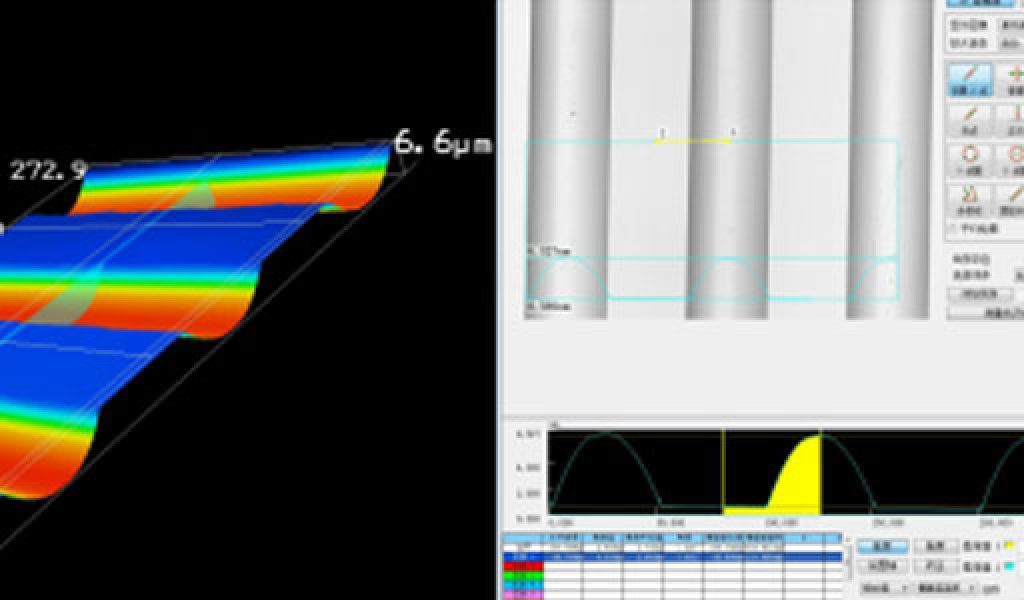

- Ultra-precision turning performance: surface roughness < Ra 0.005um, shape accuracy < 0.15 um P-V.

- The diameter of an adult’s hair is about 100 micrometers, while the minimum resolution of a BE-CU machine tool is 32 picometers, roughly one three-millionth the diameter of a hair (1/3000000).

- Length units: 1 millimeter = 1000 micrometers = 1,000,000 nanometers = 1,000,000,000 picometers.

Contact us to learn more about micro prototype and bulk nano manufacturing and how they can benefit your business. We’ll also be happy to provide a no-obligation price quote for any of our micromanufacturing services.

Nano Fabrication Process – How To Nano Manufacturing Work?

At its core, nano manufacturing operates on the principles of nanotechnology, which involves manipulating matter at the molecular and atomic levels.

The key to nano manufacturing lies in precise control over materials, processes, and structures, allowing for the creation of nano-scale features with extraordinary precision and accuracy.BE-CU realizes nano manufacturing of ultra-precision products through;

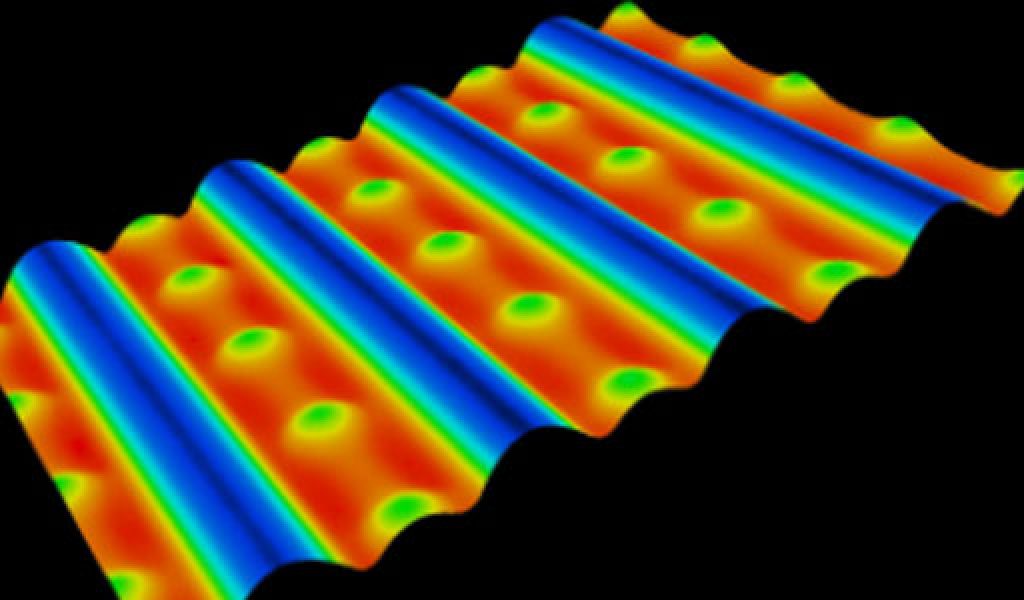

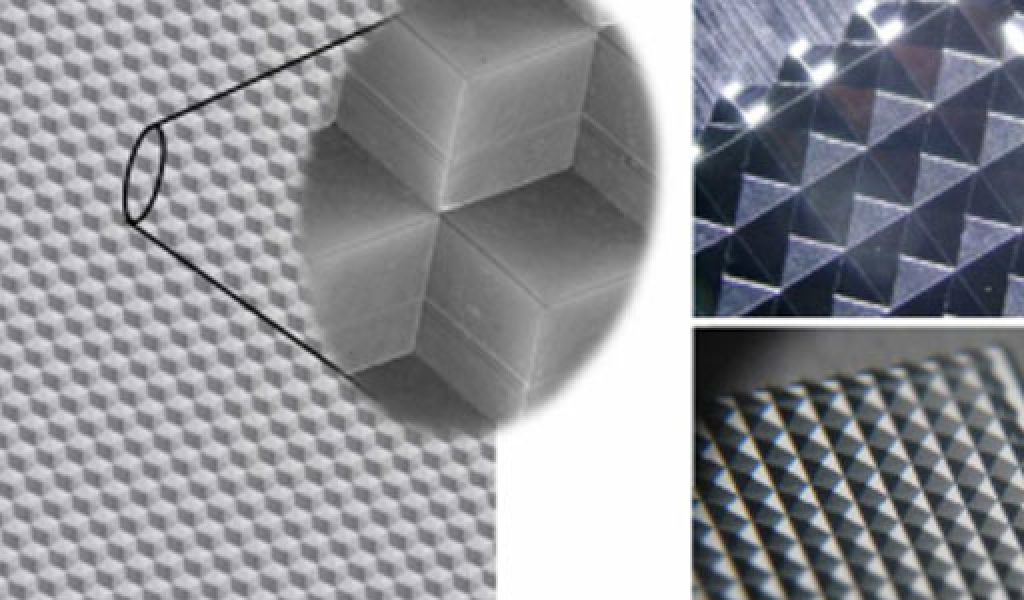

Applications include spherical surfaces, aspherical surfaces, free-form surfaces and HUD molds on various ultra-precision molds. , lens mold core, LED mold, optical lens mold, micro lens array, Fresnel, prism, compound eye structure, metal reflector, micron nozzle, etc.BE-CU Nano manufacturing encompasses a diverse range of techniques, each tailored to specific applications and materials. Some of the key techniques include:

Our Case Studies Gallery Of Nano Fabrication Parts

As our name suggests, prototype and micro manufacturing services are what we are known for. Over the past 30 years, we’ve completed thousands of projects using electrical discharge machining. What differentiates BE-CU micro nano manufacturing solutions manufacturing services from the competition is our ability to not only hold micron tolerances but to do so while still offering globally competitive pricing and lead times. Utilizing our vast knowledge of nano fabrication techniques and decades of industry experience, we are confident that we can produce your most challenging components to your exact specifications. To learn more about how BE-CU can help you contact our manufacturing team with your request for quote.

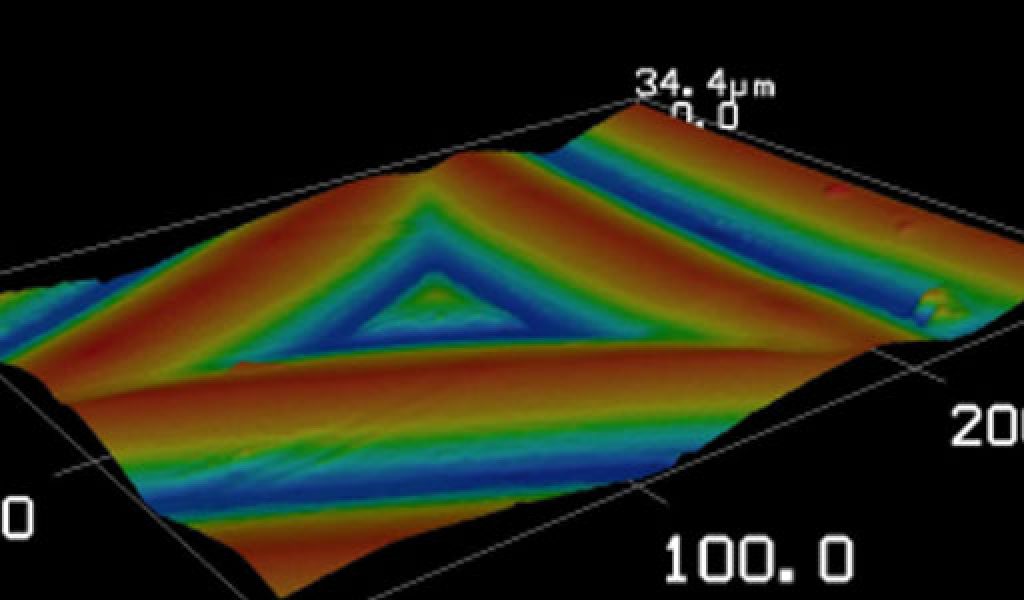

Curved-V-CUT-Structure

Light-Guide-Plate-Molds-Micro-Groove-Cut

Light-Guide-Plate-Molds-Micro-Groove-Cut

Microstructured-Small-Lens-Depth-0.5um

Prism-Die-Fabrication

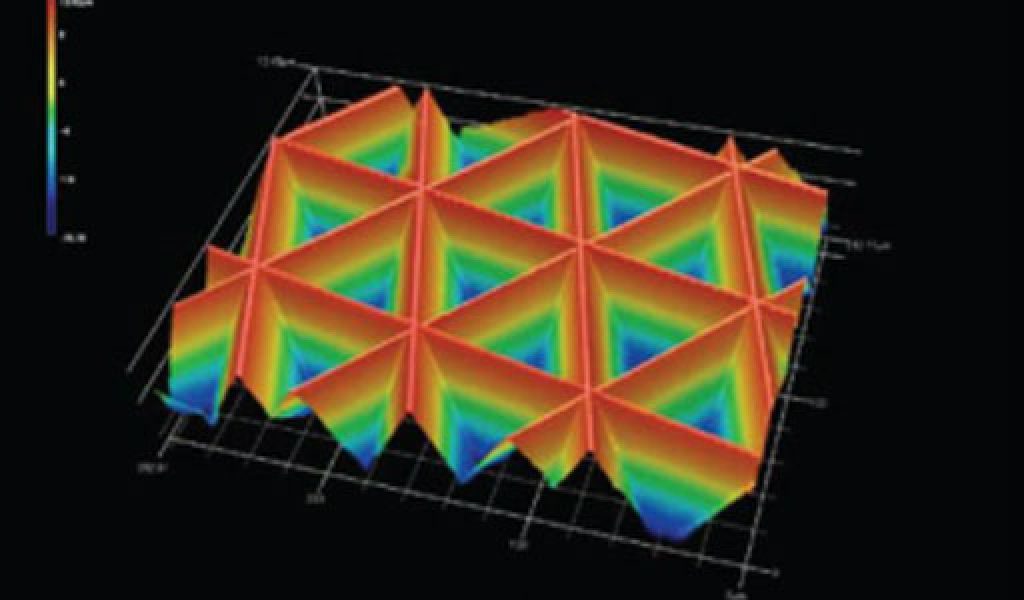

Pyramid-Fabrication

Sawtooth-Die-Tooth-Depth-1.5um

Triangular-pyramid-microstructure-array

Light-Guide-Plate-Microstructure-Mold-Core