Charging Gun Cavity

- Product name: New Energy Vehicle Charging Gun Cavity

- No+Color:Custom

- Surface treatment: Custom

- Product material: Aluminum Material

- Proofing cycle:7 days(100000 pcs/M)

- Machining Factory:BE-CU.com

- Production Process: SLM 3D Printing

- Size:According To Customer Drawings

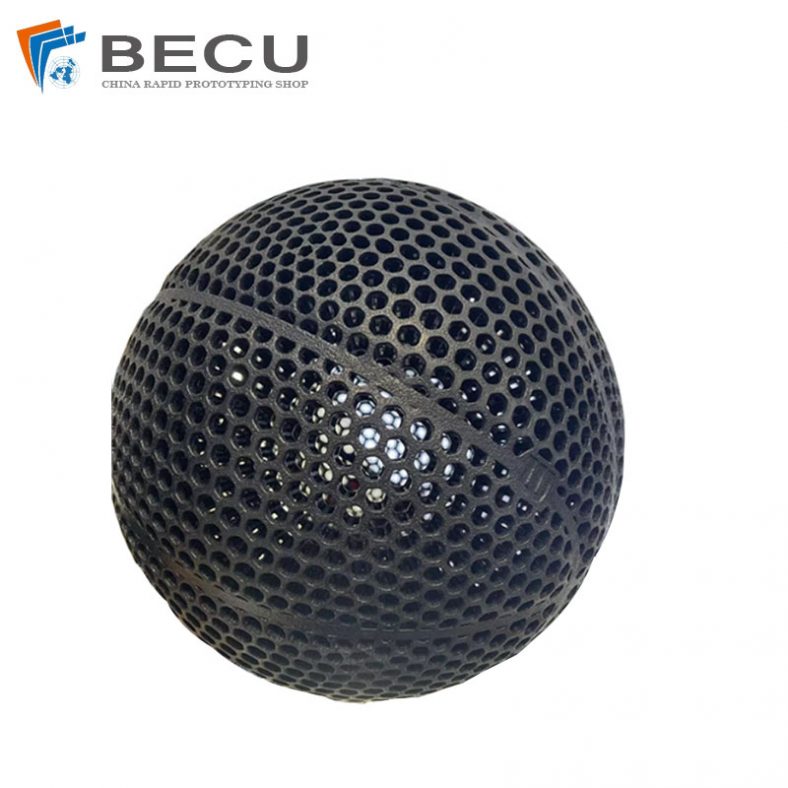

High-Quality Aluminum 3D Printing New Energy Vehicle Charging Gun Cavity

An aluminum 3D-printed new energy vehicle charging gun cavity refers to a specific component produced through additive manufacturing using aluminum as the primary material. This cavity is designed to be used in the charging gun of a new energy vehicle (NEV), which includes electric vehicles (EVs) and plug-in hybrid electric vehicles (PHEVs).

In the context of NEV charging, the charging gun is the device that connects the charging station to the vehicle for power transfer. The cavity is a critical part of the charging gun, responsible for housing various components such as electrical contacts, sensors, wiring, and mechanisms that enable the charging process.

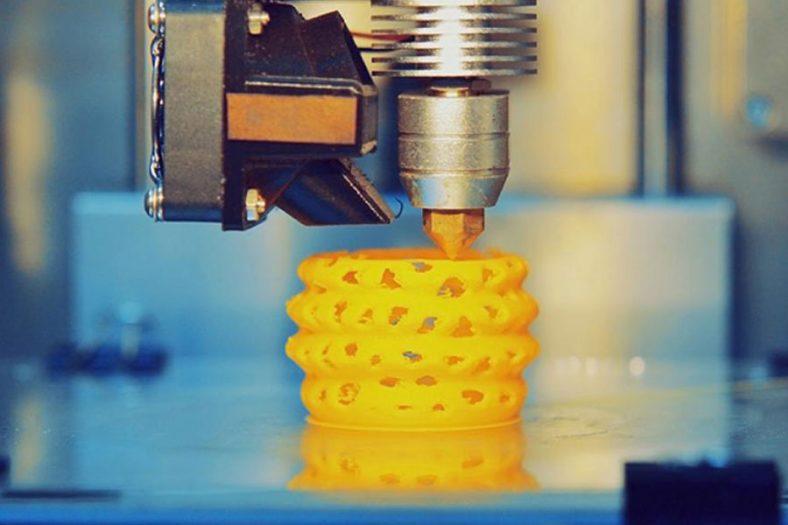

Aluminum 3D printing, also known as additive manufacturing or selective laser melting (SLM), involves the layer-by-layer deposition of aluminum powder using a laser to fuse the particles together. This additive manufacturing technique allows for the creation of complex geometries, intricate internal structures, and lightweight designs that may be challenging or impossible to achieve through traditional manufacturing methods.

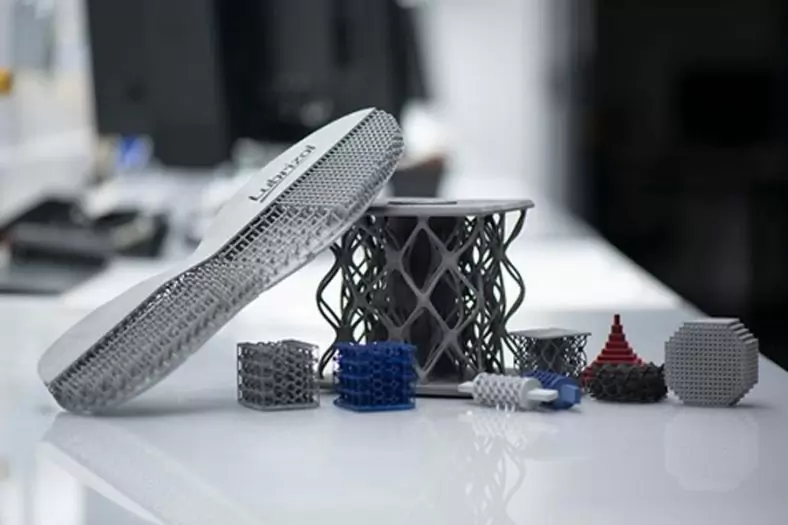

3D printing additive manufacturing services for New Energy Vehicle Aluminum Charging Gun Cavity. Capable of handling parts with +/-0.3 % as-sintered tolerance. Additional services such as digitizing, fabrication, machining, product designing and development are provided. High volume and mass production runs available. Be-Cu’s team of experienced and highly-skilled engineers and designers are always ready to complete project easier for your product team. We aim to help you achieve the best 3d printing results.

As you can see, there are good reasons to use aluminum for your next 3d printing project. With its excellent machinability and a variety of alloys and treatments available, aluminum is ideal for a wide range of applications. Be-Cu prototype offers precision CNC machining and 3d printing for many common aluminum alloys, and we can help you choose the right one.

Why Choose Aluminum 3D Printing New Energy Vehicle Charging Gun Cavity Service?

- – No minimum order quantity

- – Metal or plastic 3D printed prototype and production parts in 7-10 days

- – Precision custom 3D printing parts at affordable prices

- – Online free quote in the shortest time

- – Single prototypes or complex shapes are both allowed

- – A wide selection of metal or plastic materials

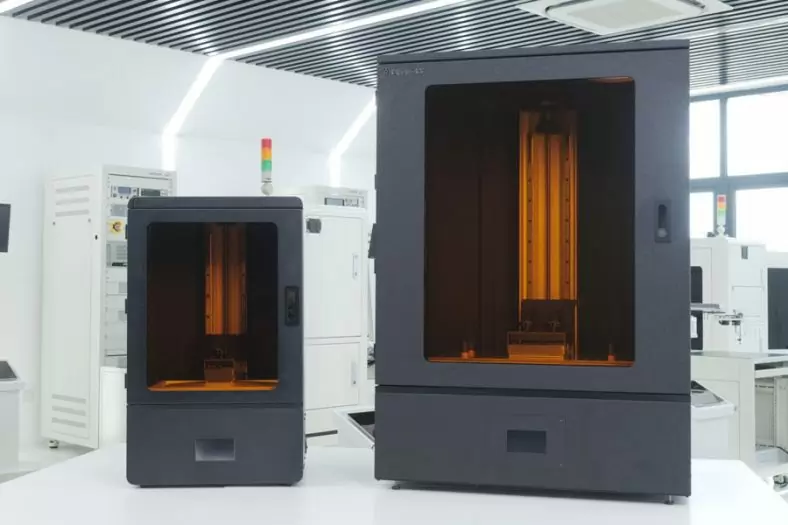

- – Commercial and industrial-grade 3D printers

- – Cooperative supplier assistance project

- – Provide a quick solution for small batches of complex prototypes

- – We provide with our partner

- – 3D printing services for metals and plastics

- – Meet the rapid needs of complex prototype designers

- – For SLA: 0.4mm wide and high

- – For SLS: 1mm wide and high

Be_Cu is your specialist when it comes to professional 3D-printing services in China. In a technical analysis we offer you the possibility of a 3D-print specific component analysis as well as a subsequent optimization of your 3D components.Right from the beginning, we work together with our customers to find suitable solutions to turn your ideas into real products. If required, we can also develop your product for 3D printing production at Be-Cu Prototype.Be-Cu has many years of experience in multicellular 3D printing processes. We are your partner for special 3D-printing processes in China, as we have a large in-house production and skillful engineers to realize your 3D-products.

Contact Be Cu Now for your Custom 3D Printing Fabrication, We are your best online 3d printing services choice!

The Specifications Of Aluminum 3D Printing New Energy Vehicle Charging Gun Cavity

| Item Name | Aluminum 3D Printing |

| Material | AlSi12 and AlSi10Mg Aluminum |

| Thickness | Custom |

| High Precision | +-0.15mm |

| Quality Control | Material Analysis、Hardness Testing、Mechanical Testing、Magnetic Particle Inspection、X Ray Testing、Leakage Testing、Ultrasonic Inspection |

| Surface Treatment | Custom (Anodized, powder coating, etc.) |

| Customized Drawings | 2D:DWG,DXF,PDF & 3D:ASM,IGS,STEP,STP .ETC |

The Detail Of BE-CU 3d printing Company

BE-CU.COM offers online 3D printing services for rapid prototyping and production in volume. Our clients are across a wide variety of industries and companies, including automotive, construction, aerospace, defense, electronics, machinery, industrial automation, medical, healthcare, consumer production, oil & gas, etc. Accelerate your product development and manufacturing process with our industry-leading metal & plastic 3D printing service and 3D printed parts. We’ll find the best 3D printing solution for your projects, to lower your cost and shorten the lead time based on your needs, while maintaining the quality. From 3D prototyping to end-use parts production, multiple materials are available for custom 3D printing parts. Need an alternative to the traditional solution? Submit your 3D CAD file to get an online quotation quickly. Our 3D printing service ensures accuracy and speed. We can help you choose the most appropriate technology and material to match your applications or request.