Carbon fiber products have a series of advantages such as light weight, high strength, corrosion resistance, high temperature resistance, anti-aging, etc., and have been used in the fields of medical equipment, rail transit, automobile industry, etc. In this article, the editor of the Be-cu mainly introduces the molding process of carbon fiber products.Carbon fiber composite material compression molding is a manufacturing process, which is characterized by using a mold to hot-press mold prepregs at a certain temperature and pressure to obtain high-performance composite products. The process characteristics and process flow of carbon fiber composite molding will be introduced in detail below.

Characteristics Of Carbon Fiber Molding Process

- High precision: The carbon fiber composite material molding process can produce high-precision composite products with high dimensional accuracy and surface finish.

- High performance: Since carbon fiber has high strength, high rigidity and corrosion resistance, carbon fiber composite molded products have excellent properties, such as high strength, high rigidity, corrosion resistance, etc.

- High production efficiency: The carbon fiber composite molding process is an efficient production method with a short production cycle and can achieve large-scale production.

- Wide scope of application: The carbon fiber composite molding process is suitable for products of various shapes and sizes, such as auto parts, aircraft parts, sports equipment, etc.

Process Flow Of Carbon Fiber Molding Process

The carbon fiber composite material compression molding process includes the following steps:

- Raw material preparation: Prepare raw materials such as carbon fiber and resin, and conduct inspection and measurement.

- Mold preparation: Design and manufacture the mold, its size and shape are determined according to the product requirements.

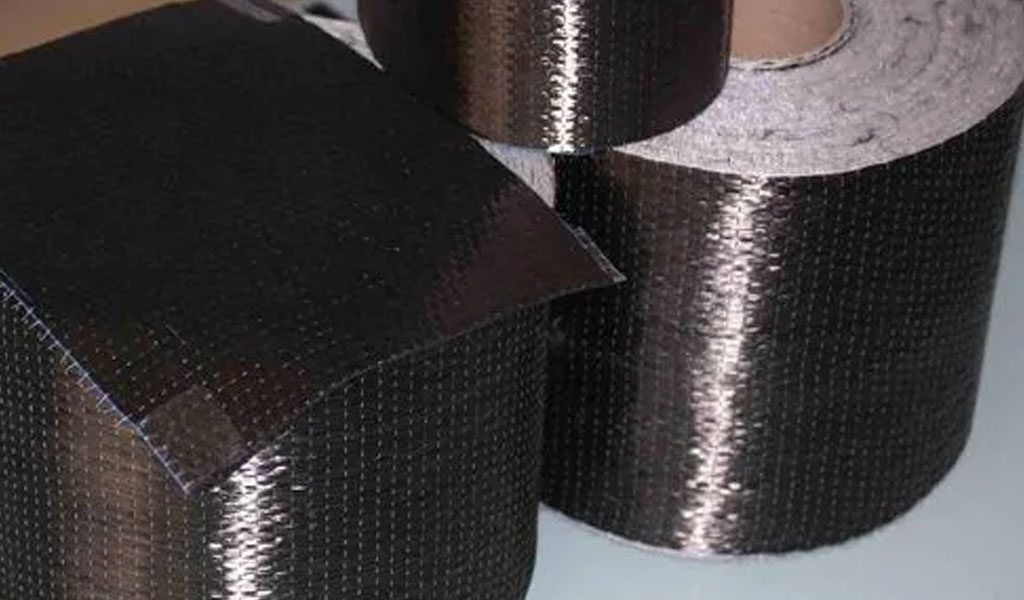

- Prepreg preparation: Mix raw materials such as carbon fiber and resin in a certain proportion to prepare prepreg.

- Laying: Lay the prepreg in the mold in a certain way and eliminate air bubbles.

- Hot pressing: Put the prepreg-paved mold into a hot press and perform hot pressing at a certain temperature and pressure.

- Cooling: Cool the hot-pressed products to room temperature, and perform trimming and post-processing.

- Demolding: Remove the product from the mold and conduct quality inspection and trimming.

- Post-processing: Surface treatment, processing and other post-processing are performed on the products to meet the usage requirements.

Influencing Factors Of Carbon Fiber Molding Process

The influencing factors of the carbon fiber composite molding process mainly include the following aspects:

- Raw material quality: The quality of raw materials has an important impact on the performance and cnc machining service life of the product. Therefore, raw material suppliers with stable quality should be selected and strict quality control of raw materials should be carried out.

- Mold design: Mold design has an important impact on the shape, size and quality of the product. Therefore, experienced mold designers should be selected and reasonable designs should be carried out according to product requirements.

- Hot pressing temperature and pressure: Hot pressing temperature and pressure have an important impact on the performance and service life of the product. Therefore, the appropriate hot pressing temperature and pressure should be selected to ensure the quality and performance of the product.

- Laying method: Laying method has an important impact on the performance and service life of the product. Therefore, the appropriate layering method should be selected according to the product requirements, and the layering quality should be strictly controlled.

- Cooling speed: Cooling speed also has an important impact on the performance and service life of the product. Therefore, an appropriate cooling rate should be selected to ensure the quality and performance of the product.

Application Examples Of Carbon Fiber Molding Process

The carbon fiber composite material compression molding process has been widely used in automobile manufacturing, aerospace, sports equipment and other fields. For example, carbon fiber composite bumpers, racing car bodies and other components used in automobile manufacturing; carbon fiber composite fuselages, wings and other components used in the aerospace field; carbon fiber composite bicycle frames, golf clubs, etc. used in the sports equipment field. These products are manufactured using carbon fiber composite compression molding processes and offer excellent performance and service life.

First of all, it is necessary to calculate the material area and number of sheets of carbon fiber prepreg according to the specifications of the required products, and then clean the mold, clean up the residual resin and sundries from the last use, and ensure the mold is clean and tidy.

A certain amount of release agent is applied to the tank, and then the carbon fiber prepreg is laminated to the mold layer by layer. When all the prepregs are laminated, the mold is closed, sent to the press, and cured at high temperature.

In the molding process, there are three factors to pay attention to, namely temperature, pressure and time. Temperature determines the heat transfer conditions of the mold to the material in the cavity, and has a decisive influence on the melting, flow and solidification process of the material. The pressure closes the mold tightly and densifies the material, promotes the flow of the material and balances the pressure generated by the volatilization of low molecular weights in the mold cavity. The length of time determines whether the molded shape can be cured.

China Be-cu Prototype Material Technology Co., Ltd. is a professional manufacturer of carbon fiber products. The company has large-scale hot presses, autoclaves, hydraulic forming tables, CNC high-speed milling machines and other large-scale equipment. The company’s products are made from Taiwan, Japan, etc. Well-known brand raw materials production, quality assurance.

ISO 9001 certified. BE-CU Prototype Offering CNC machining carbon fiber and other manufacturing services for carbon fiber marterial. Various capabilities include notching, labeling, drilling carbon fiber, grinding, laser cutting carbon fiber, finishing, plating, marking, CNC milling carbon fiber and turning carbon fiber.We stock high quality 3k carbon fiber sheet in a variety of thickness, types and finish. Its a great material used in applications where light weight and strength are needed such as drones. Unlike other workshops, we have no min order and are often filling orders with a single part. We also don’t make you pay for the full sheet and you only get charged for what is used. With a large selection of material, you should find everything you need to make your project come to life. We are also able to handle larger production runs and provide a competitive pricing. If we don’t have the material or finish you require, we are more the willing to look at bringing it in for you.

What Is Carbon Fiber?Carbon fiber is made of polyacrylonitrile (PAN) (or pitch, viscose) and other organic fibers by carbonization (removal of most elements except carbon) by pyrolysis method under inert gas at high temperature above 1,000 °C. Inorganic polymer fibers with a carbon content of more than 90%.

-

3D Printing Continuous Fibres

-

3D Printing Short Fibre Filled Wires

-

Laser Cutting Carbon Fiber Positioning Keyboard

-

Cnc Turning Industrial Copper-Aluminum Clad Carbon Fiber Machinery Parts

-

Carbon Fiber Luggage Tag Ornaments

-

Laser Cutting Carbon Fiber Guitar Shape Crafts

-

Laser Cutting Carbon Fiber Drone Rack

-

Cnc Milling Carbon Fiber Finger Buckle