Robot is an intelligent mechanical device that assists or replaces human work. Its application is more and more extensive. The mechanical arm is its main working part, and it has certain requirements for the production material. In this article, let’s take a look at the carbon fiber robotic arm application advantages.

Lightweight is the most well-known advantage of carbon fiber composite materials. The mechanical arm made of carbon fiber composite materials can effectively realize the light weight of the structure, which is more convenient in the actual operation process. While reducing weight, the mechanical properties of carbon fiber composites are also very prominent, which can effectively meet the strength requirements during use.

The operation accuracy is also very important for the robot arm. On the one hand, the mechanical properties of carbon fiber composite materials are outstanding, and there is basically no bending deformation.

At the same time, the thermal expansion coefficient of carbon fiber composite materials is small, and it basically does not deform with the change of working temperature. Dimensionally stable to ensure operation accuracy.

With the continuous improvement of functions, industrial robots have gained “use” in a variety of application scenarios. In the past decade, industries such as automobile manufacturing, metal products, electronics, rubber/plastic production, and logistics and warehousing have achieved faster development through the efficiency of industrial robots. From 2013 to 2020, the market size of industrial robots has continued to grow at an average annual rate of 12%, with global sales in the tens of billions of dollars. In the context of rising labor costs, industrial robots with higher flexibility, stronger obstacle avoidance and rapid configuration capabilities have become one of the most important roles in the intelligent equipment industry.

Industrial robots can not only complete common tasks such as dispensing, welding, spraying, heat treatment, transportation, assembly, and inspection, but also perform special tasks such as drilling, riveting, sealing, trimming, composite material laying, and non-destructive detection. Improving product output and quality stability has significant effects.

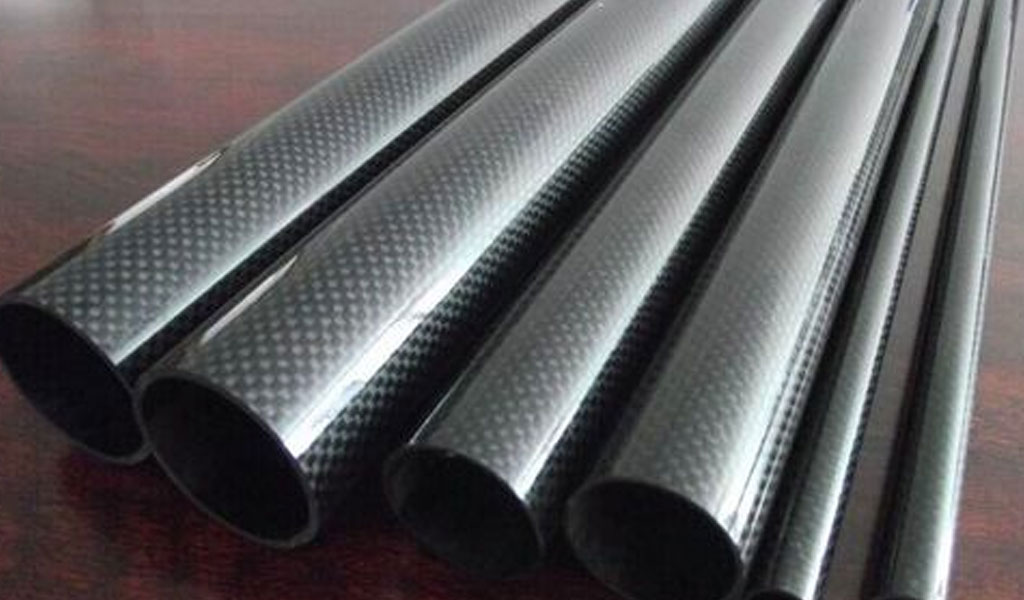

Large Carbon Fiber Robotic Arm

“Industry 4.0” puts forward high requirements for the intelligence of robots. In addition to relying on core technologies such as big data, artificial intelligence, and 5G, intelligent industrial robots also have equally high requirements for materials. Lightweight and low energy consumption are the basic requirements for raw materials for intelligent industrial robots. Carbon fiber composite materials have a light specific gravity and high strength. Using them to make mechanical arms, mechanical joints and outer shells of industrial robots can effectively improve the stiffness of the application objects and have a significant effect on reducing the overall weight. The lightweight and high strength of the material also greatly improves the work efficiency and energy saving effect of industrial robots. In addition, carbon fiber composite materials are corrosion-resistant, have extremely small thermal expansion coefficients, and have stable physical properties. The products have excellent fatigue resistance and are not easy to deform. They can reduce maintenance frequency and extend service life.

Carbon Fiber Telescopic Robotic Arm

Carbon fiber robotic arms are the most common application of carbon fiber composite materials in industrial robots. Be-Cu prototyping alone has customized hundreds of carbon fiber robotic arms for more than ten domestic robot brands in recent years. These The robotic arms have different functions such as exploration, detection, sorting, and transportation, and play a unique role in different fields such as electric power, tunnel engineering, and intelligent precision and micro manufacturing.

According to relevant personnel from Be-Cu prototyping , this type of carbon fiber robotic arms adopt advanced molding technology, and product accuracy can be guaranteed to high standards. Some robot arm tubes are larger in size. If they are made of traditional metal materials, such as manufacturing stainless steel or aluminum alloy, their strength can reach the requirements in a short time.

However, the performance defects of metal will become more obvious as the size of the robotic arm increases. The larger the size, the greater the self-weight of the component. After a long period of working pressure, its fatigue resistance will be weakened due to excessive self-weight, and it is easy to produce localized parts. Cumulative damage, when the damage reaches a certain level, it will break, which may cause equipment failure and cause safety issues. The carbon fiber composite material used by Be-Cu prototyping to make the robotic arm can not only reduce the weight by 30%-60%, but also provide some functions that cannot be achieved by traditional metal robotic arms, such as a telescopic robotic arm due to its own weight. It is much lower and has high strength, so this robotic arm can be designed more perfectly due to changes in materials. It can not only increase the arm length, expand the working range, but also carry more detection and intelligent control equipment, increasing the application of industrial robots. value.

Carbon Fiber Industrial Robot Joints

For a strong industrial country, materials come first. In the era of “Industry 4.0”, the power of “it” cannot be ignored. Carbon fiber robotic arms have important strategic significance for realizing high-speed and high-precision motion control of industrial robots, improving the application level of industrial robots in my country, and enhancing industrial competitiveness.

Some robotic arms may face some special or harsh working environments. Carbon fiber is a non-metallic material with low electrochemical activity. long lasting. In addition, the carbon fiber composite material also has the characteristics of high temperature resistance, which can adapt to the high temperature working environment and ensure the safety of use.

China Be-cu Prototype Material Technology Co., Ltd. is a professional manufacturer of carbon fiber products. It has large-scale hot presses, autoclaves, hydraulic forming tables, CNC high-speed milling machines and other large-scale equipment. The products produced by the china cnc machining company are made of Taiwan, Japan and other well-known brands of raw materials production, quality assurance.

ISO 9001 certified. BE-CU Prototype Offering CNC machining carbon fiber and other manufacturing services for carbon fiber marterial. Various capabilities include notching, labeling, drilling carbon fiber, grinding, laser cutting carbon fiber, finishing, plating, marking, CNC milling carbon fiber and turning carbon fiber.We stock high quality 3k carbon fiber sheet in a variety of thickness, types and finish. Its a great material used in applications where light weight and strength are needed such as drones. Unlike other workshops, we have no min order and are often filling orders with a single part. We also don’t make you pay for the full sheet and you only get charged for what is used. With a large selection of material, you should find everything you need to make your project come to life. We are also able to handle larger production runs and provide a competitive pricing. If we don’t have the material or finish you require, we are more the willing to look at bringing it in for you.

What Is Carbon Fiber?Carbon fiber is made of polyacrylonitrile (PAN) (or pitch, viscose) and other organic fibers by carbonization (removal of most elements except carbon) by pyrolysis method under inert gas at high temperature above 1,000 °C. Inorganic polymer fibers with a carbon content of more than 90%.

-

3D Printing Continuous Fibres

-

3D Printing Short Fibre Filled Wires

-

Laser Cutting Carbon Fiber Positioning Keyboard

-

Cnc Turning Industrial Copper-Aluminum Clad Carbon Fiber Machinery Parts

-

Carbon Fiber Luggage Tag Ornaments

-

Laser Cutting Carbon Fiber Guitar Shape Crafts

-

Laser Cutting Carbon Fiber Drone Rack

-

Cnc Milling Carbon Fiber Finger Buckle