With the continuous development of science and technology, the application of robots has gradually increased. Our common robots are mainly industrial robots to replace human beings to perform heavy and single work and reduce labor intensity. The mechanical arm is the main part of the work. Carbon fiber machinery Arms are gradually being used instead of traditional metal robotic arms. Let’s take a look at the performance advantages of carbon fiber robotic arms.

The most significant advantage of carbon fiber material is its light weight, its density is only 1.7g/cm3, which is 60% of the traditional weight reduction material aluminum alloy, less than 1/4 of that of steel, which helps to achieve lightweight structure and more convenient operation. , and can prevent the problem of unstable center of gravity caused by the excessive weight of the arm itself.The mechanical arm is the main part of the work, and it is also the main load-bearing member. It needs good support performance. The specific strength and specific stiffness of carbon fiber materials are better than most structural materials, and the load-bearing performance is outstanding. When a few fibers are broken, the load will be rapid. Distributed to other unbroken fibers, it will not cause damage in a short time, and has good fatigue resistance.

Speaking of robotic arms, everyone must be familiar with them. Robotic arms are the most widely used automated mechanical devices in the field of robotics technology. They can be seen in industrial manufacturing, medical treatment, entertainment services, military, semiconductor manufacturing, space exploration and other fields. Traditional robot arms are made of metal. During use, it was found that metal robot arms have a relatively high weight and are prone to wear and deformation after long-term use. This led to the emergence of carbon fiber robot arms. What are the advantages of carbon fiber robot arms? Woolen cloth?

Low Energy Consumption, Light Load, Easy To Use

Traditional robot manipulator arms are still mainly made of metal materials. In order to improve the quality of the manipulator arm, the weight often increases, the accuracy is not enough, and it is easy to wear and deform during long-term use. If you adopt a thinner design, you will find that its strength is not enough and it is prone to complete deformation, causing damage to the robotic arm. The advantages of carbon fiber robotic arms are obvious. Carbon fiber itself is a high-performance material with light weight and high strength. It performs well in many products that require lightweighting. When used in the production of robotic arms, it can reduce the weight of the robotic arms and can also Improve the accuracy of the robotic arm and reduce uneven product quality caused by vibration.

High Strength And Good Load-Bearing Performance

Carbon fiber robotic arms, because of the carbon fiber material, make the entire mass lighter, and the grabbing performance of the carbon fiber robotic arms is also very good. This is because although the density of carbon fiber materials is low, the overall strength is very high, which allows the carbon fiber robotic arms to When grabbing very heavy products, the tensile strength of carbon fiber material can reach 3500MPa, and the axial force in the fiber can reach more than 5 times that of common metal steel. In addition, the advantages of carbon fiber robotic arms in fatigue resistance are also very obvious, and they can be used in some special environments without worrying about corrosion or rust.

High Overall Precision And Performance

When using robotic arms, especially assembly line robotic arm products, high accuracy is required. The thermal expansion coefficient of carbon fiber composite materials is very small and can adapt to working environments with large temperature differences. In use, including in some special environments, it still has good dimensional accuracy, which can more effectively ensure the accuracy of welding. The more accurate carbon fiber robotic arm has a higher competitive advantage in practical applications. This is something that ordinary metal materials cannot do.

Longer Service Life

Compared with metal materials, robotic arms made of carbon fiber composite materials have better fatigue resistance and require less frequent maintenance or updates. There are thousands of filaments inside the carbon fiber material, and each filament is bonded by resin. This allows the carbon fiber robotic arm to remain very stable when it is impacted during use. In the application of the robotic arm, that When the robotic arm is impacted, it can disperse the force well and better ensure the overall performance of the robotic arm. When it is subjected to force impact, it will also more effectively ensure the stability of the entire robotic arm. If it is a robotic arm that works for a long time, corresponding layers will be laid on top of the force, so that the mechanical arm can withstand stress. The force is better, which further makes the entire impact resistance better and greatly extends the service life of the mechanical arm.

The operation accuracy is also very important for the robot arm. The performance of traditional metal materials is unstable and prone to corrosion, and the strength of metal materials is not high and easy to deform. Carbon fiber is a non-metallic material with excellent corrosion resistance and anti-aging properties and long service life. Its thermal expansion coefficient is small, and it will not creep with the change of operating temperature, thus ensuring accurate operation.

China Be-cu Prototype Material Technology Co., Ltd. is a professional manufacturer of carbon fiber products, which can meet the needs of customers for carbon fiber products in various fields such as rail transit, cnc machining medical equipment, rail transit, etc. The carbon fiber products are made of well-known brand raw materials from Taiwan and Japan. Production, quality assurance.

ISO 9001 certified. BE-CU Prototype Offering CNC machining carbon fiber and other manufacturing services for carbon fiber marterial. Various capabilities include notching, labeling, drilling carbon fiber, grinding, laser cutting carbon fiber, finishing, plating, marking, CNC milling carbon fiber and turning carbon fiber.We stock high quality 3k carbon fiber sheet in a variety of thickness, types and finish. Its a great material used in applications where light weight and strength are needed such as drones. Unlike other workshops, we have no min order and are often filling orders with a single part. We also don’t make you pay for the full sheet and you only get charged for what is used. With a large selection of material, you should find everything you need to make your project come to life. We are also able to handle larger production runs and provide a competitive pricing. If we don’t have the material or finish you require, we are more the willing to look at bringing it in for you.

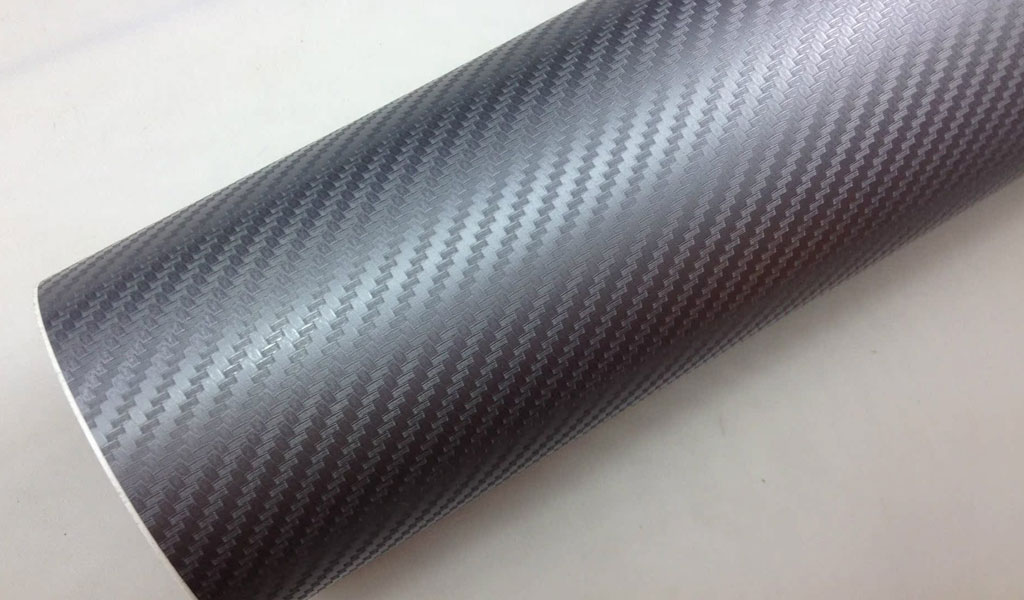

What Is Carbon Fiber?Carbon fiber is made of polyacrylonitrile (PAN) (or pitch, viscose) and other organic fibers by carbonization (removal of most elements except carbon) by pyrolysis method under inert gas at high temperature above 1,000 °C. Inorganic polymer fibers with a carbon content of more than 90%.

-

3D Printing Continuous Fibres

-

3D Printing Short Fibre Filled Wires

-

Laser Cutting Carbon Fiber Positioning Keyboard

-

Cnc Turning Industrial Copper-Aluminum Clad Carbon Fiber Machinery Parts

-

Carbon Fiber Luggage Tag Ornaments

-

Laser Cutting Carbon Fiber Guitar Shape Crafts

-

Laser Cutting Carbon Fiber Drone Rack

-

Cnc Milling Carbon Fiber Finger Buckle