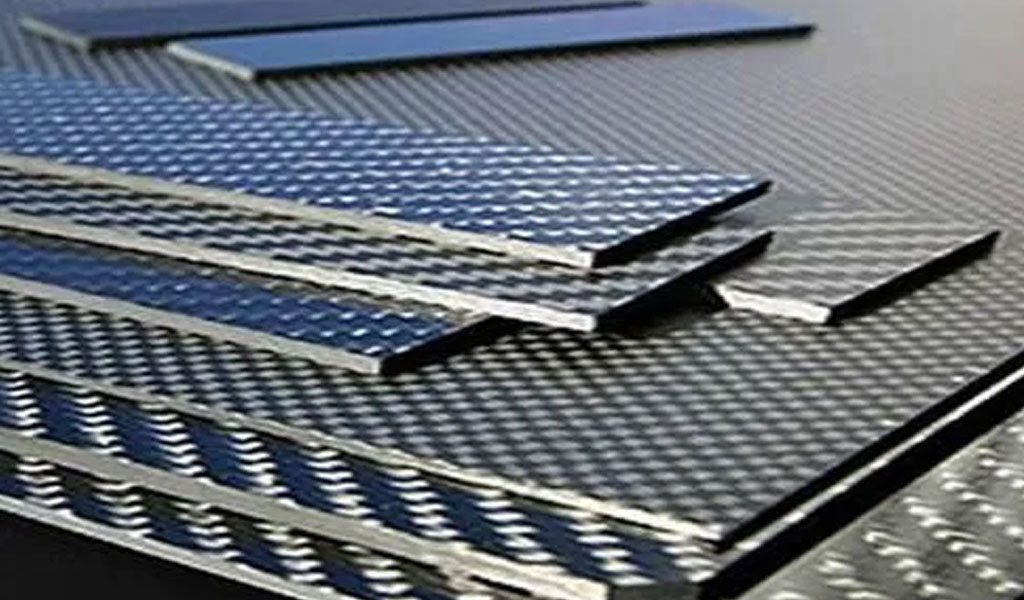

Carbon fiber is durable, lightweight, resistant to high temperatures and corrosion. It is a multifunctional composite material suitable for many occasions. It has huge potential in the medical industry.

The medical industry is always growing and innovating, and new technologies require the best materials, and carbon fiber is one of them. The use of carbon fiber in the medical field has revolutionized the way medical equipment is designed and micro manufactured, resulting in more efficient and effective treatments for patients. This article mainly introduces seven typical applications of carbon fiber in the medical and health field.Autoclave is a device for curing carbon fiber resin matrix composite products, which has five functions of heating, heat preservation, cooling, pressurization and vacuuming. The products made with it have low porosity and good quality consistency. In this article, the editor will tell you about the autoclave forming process of carbon fiber composite materials.

The Composition Of The Autoclave System

Pressurization system: used for inflation and pressurization, the maximum pressure process is determined, the pressure can be adjusted, and there are safety explosion-proof and air release devices.

- Vacuum system: including vacuum tank, vacuum meter, vacuum pipeline, to meet the process requirements of vacuuming, and the degree of vacuum is adjustable.

- Heating system: The temperature difference in the tank is less than 5°C, and the heating rate is 1~8°C, which can be adjusted as required.

- Cooling system: circulating water cooling, the cooling rate is 0.5~6℃/min, adjustable. Feeding system: including trolley, connecting bridge, ground track, etc.

- Control system: automatic control by computer monitoring, or manual control, monitoring various elements such as temperature and pressure.

- Blower system: including motors, fans, air deflectors, etc., to ensure that the wind speed in the tank is 1~3m/s, and the noise is less than 60dB.

- Instrument valves: including mechanical instruments, electronic sensors, mechanical and electronic instruments, etc.

The Process Of Manufacturing Carbon Fiber Products With Autoclave

1. The Molding Process

Carbon fiber prepreg blanking → laying blanks → pre-adhesive glue → blank trimming → curing → demoulding → non-destructive testing → machining → inspection and storage

2. Curing Process

Lay up blanks → make vacuum bags → vacuum leak detection → workpieces into the tank → open the heating program → pressurization → heat preservation and pressure preservation → cooling → pressure reduction and shutdown → workpieces out of the tank

Notes For Autoclave Forming:

- Lamination: The structural design and lamination design of carbon fiber should consider the stackability, and the thickened concave area can be in the form of ribs. For non-deployable layers, partial openings or splices are used.

- Thickness deviation: generally controlled at 8%, important areas controlled at 5%, and post-machining if the requirements are too high.

- Corner: Avoid sharp corners at the corners, and the radius of the inner circle of the arc transition should be greater than the wall thickness, that is, R>t.

- Drafting slope: For closed structures and small closed-angle structures, try to design a larger drafting slope when the assembly and use functions allow.

China Be-cu Prototype Material Technology Co., Ltd. has strong technical force. It not only has mature autoclave forming process, but also masters various carbon fiber product forming processes such as molding, winding, pultrusion, and weaving. The main products include carbon fiber board, carbon fiber automobile high-speed rail accessories , carbon fiber drive shaft and manipulator.

ISO 9001 certified. BE-CU Prototype Offering CNC machining carbon fiber and other manufacturing services for carbon fiber marterial. Various capabilities include notching, labeling, drilling carbon fiber, grinding, laser cutting carbon fiber, finishing, plating, marking, CNC milling carbon fiber and turning carbon fiber.We stock high quality 3k carbon fiber sheet in a variety of thickness, types and finish. Its a great material used in applications where light weight and strength are needed such as drones. Unlike other workshops, we have no min order and are often filling orders with a single part. We also don’t make you pay for the full sheet and you only get charged for what is used. With a large selection of material, you should find everything you need to make your project come to life. We are also able to handle larger production runs and provide a competitive pricing. If we don’t have the material or finish you require, we are more the willing to look at bringing it in for you.

What Is Carbon Fiber?Carbon fiber is made of polyacrylonitrile (PAN) (or pitch, viscose) and other organic fibers by carbonization (removal of most elements except carbon) by pyrolysis method under inert gas at high temperature above 1,000 °C. Inorganic polymer fibers with a carbon content of more than 90%.

-

3D Printing Continuous Fibres

-

3D Printing Short Fibre Filled Wires

-

Laser Cutting Carbon Fiber Positioning Keyboard

-

Cnc Turning Industrial Copper-Aluminum Clad Carbon Fiber Machinery Parts

-

Carbon Fiber Luggage Tag Ornaments

-

Laser Cutting Carbon Fiber Guitar Shape Crafts

-

Laser Cutting Carbon Fiber Drone Rack

-

Cnc Milling Carbon Fiber Finger Buckle