Joint stiffness is a common clinical morbid phenomenon. One of the reasons is that the joint and its surrounding tissues are severely injured or invaded by disease, which destroys the joint synovium, resulting in the healing of joint fibers and secondary adhesions, thus causing certain damage to the limbs. With the progress of medicine, there have been certain solutions, such as: joint adhesion relaxation, nylon, silicone sheet and other built-in to prevent joint adhesion. At present, there is a more effective solution, which is to replace the knee joint synovium with a special carbon fiber braid treated with high technology. The results proved that the carbon fiber braid can replace the joint synovium and induce regeneration of new synovium, while eliminating joint adhesions.

View More Articles:

What Is Joint Synovium

Joint synovium is a critical part of the human body’s joints, as it produces synovial fluid, which lubricates and nourishes the joint. It also helps to maintain joint stability and function.

While carbon fiber and other advanced materials have found applications in various fields, including medical devices and orthopedic implants, replacing joint synovium with carbon fiber braid or any material is not a standard or established medical procedure.

Joint replacement surgeries, when necessary, typically involve replacing damaged or diseased joints with prosthetic devices made of biocompatible materials like metals (e.g., titanium) or ceramics. These devices aim to mimic the natural joint’s function and movement.

Medical science and technology continue to advance, and there may be ongoing research in the field of joint replacement and tissue engineering that I’m not aware of as of my last update. However, it’s important to note that any potential replacement for joint synovium would need to meet stringent safety, compatibility, and effectiveness criteria, which would require extensive research, testing, and regulatory approval before becoming a viable medical procedure.

The Material Of Replace Joint Synovium

When a joint’s synovium is damaged or needs replacement, the most common approach is to perform a procedure called synovectomy or synovial membrane replacement. The synovium is the inner lining of a joint capsule responsible for producing synovial fluid, which lubricates and nourishes the joint. It can become damaged due to injury, inflammation (such as in rheumatoid arthritis), or other joint diseases.

There are a few options for replacing or repairing the synovium:

- Synovectomy: In cases where the synovium is inflamed or overgrown due to conditions like rheumatoid arthritis, a synovectomy may be performed. This involves the removal or reduction of the inflamed synovial tissue. After the procedure, the remaining healthy synovium can continue to produce synovial fluid.

- Tissue Grafts: In some cases, especially if the synovium is severely damaged or needs to be entirely replaced, tissue grafts can be used. Autografts, allografts, or xenografts are options:

- Autograft: Tissue is taken from another part of the patient’s own body, often from a healthy synovium in a less critical joint.

- Allograft: Tissue is taken from a donor of the same species, usually a cadaveric source. It may be processed and sterilized before implantation.

- Xenograft: Tissue is taken from a different species and may be modified to reduce the risk of rejection.

- Synovial Tissue Engineering: Researchers are also exploring the use of tissue engineering techniques to create synthetic synovial tissue for implantation. This involves growing cells in a laboratory setting and then using them to construct a synthetic synovial lining.

- Biological Therapies: In some cases, biological therapies, such as platelet-rich plasma (PRP) or stem cell therapy, may be considered to stimulate the body’s natural healing processes and promote synovial tissue repair.

The choice of material or technique used to replace the joint synovium depends on the specific condition, the extent of damage, and the patient’s overall health. It’s crucial to consult with a qualified orthopedic surgeon or rheumatologist who can assess your specific situation and recommend the most appropriate treatment option.

The Advantage Of Carbon Fiber Braid

In recent decades, the use of carbon fiber to replace artificial bone, joint ligaments and the use of carbon fiber to repair knee injuries have made great progress. The reason why carbon fiber can attract the attention of the medical community at home and abroad is because of its good biocompatibility. , Using fast neutron radiation carbon fiber braid, strictly eliminate organic and inorganic impurities, non-toxic, non-stimulating, anti-coagulant, non-carcinogenic to living tissue. There is also the use of glassy carbon to manufacture various organs of the human body, such as teeth, heart valves, Google, bone joints, ligaments, etc., and achieved different degrees of curative effect.

The process of tissue regeneration induced by carbon fiber braid is that the implanted carbon fiber material naturally forms a porous mesh frame, and the protrusions of blood vessels and fibrous cells proliferate along the mesh, forming a synovial prototype composed of a layer of “simulated synovial cells”. , and then synovial cells change from monolayer to stratified and finally form a complete synovium.

At present, there are many clinical medical devices that use carbon fiber materials, such as carbon fiber flat panel detectors, carbon fiber medical CT bed plates, carbon fiber breast machine support plates, carbon fiber orthopedic traction frames, etc. You can visit the carbon fiber products column to learn more about China Be-cu Prototype Material Technology Co., Ltd. was established in 2007, specializing in the production and machining of carbon fiber. The products include carbon fiber cloth, plates, rods, tubes, special-shaped parts, etc. If you need to process or buy carbon fiber, you can call our staff.

ISO 9001 certified. BE-CU Prototype Offering CNC machining carbon fiber and other manufacturing services for carbon fiber marterial. Various capabilities include notching, labeling, drilling carbon fiber, grinding, laser cutting carbon fiber, finishing, plating, marking, CNC milling carbon fiber and turning carbon fiber.We stock high quality 3k carbon fiber sheet in a variety of thickness, types and finish. Its a great material used in applications where light weight and strength are needed such as drones. Unlike other workshops, we have no min order and are often filling orders with a single part. We also don’t make you pay for the full sheet and you only get charged for what is used. With a large selection of material, you should find everything you need to make your project come to life. We are also able to handle larger production runs and provide a competitive pricing. If we don’t have the material or finish you require, we are more the willing to look at bringing it in for you.

What Is Carbon Fiber?Carbon fiber is made of polyacrylonitrile (PAN) (or pitch, viscose) and other organic fibers by carbonization (removal of most elements except carbon) by pyrolysis method under inert gas at high temperature above 1,000 °C. Inorganic polymer fibers with a carbon content of more than 90%.

-

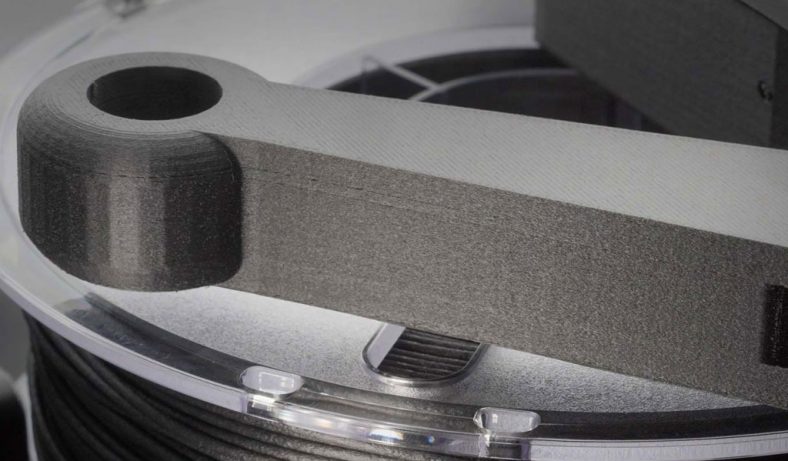

3D Printing Continuous Fibres

-

3D Printing Short Fibre Filled Wires

-

Laser Cutting Carbon Fiber Positioning Keyboard

-

Cnc Turning Industrial Copper-Aluminum Clad Carbon Fiber Machinery Parts

-

Carbon Fiber Luggage Tag Ornaments

-

Laser Cutting Carbon Fiber Guitar Shape Crafts

-

Laser Cutting Carbon Fiber Drone Rack

-

Cnc Milling Carbon Fiber Finger Buckle