If the CNC machine tool is used for milling and grinding, the high precision of aluminum-based silicon carbide machining can be finely controlled, milling and grinding, the milling width of the tool, and the spindle speed can be controlled quickly and stably. The machining parameters of silicon need to be controlled to a certain extent. At this time, it is necessary to carry out the next reference and actual research.

CNC Machining Aluminum Silicon Carbide

At this time, it is possible to obtain the precise control of excellent grinding machining. So what about the CNC machining method of aluminum silicon carbide? Be-Cu Ceramics attaches great importance to product quality, product demand and good service attitude.

Only by maintaining good quality and good attitude can we attract the attention of more customers, and only by getting the attention of customers can we receive more orders.

In recent years, the development of aluminum-based silicon carbide composite materials has been greatly improved in today’s society. The application fields of this special material are also relatively wide.

The commonly used machining equipment is CNC engraving and milling machine machining, CNC machining of aluminum-based carbide Among the silicon methods, this machining method is one of the most common machining methods. It is mainly to use CNC engraving and milling machines for milling and grinding machining. The machining efficiency of this kind of machinery will be better.

This aluminum-based silicon carbide composite material not only has the high plasticity of metal, but also has the high brittleness of ceramics and is widely used in many fields. It also has the advantages of high specific strength, high stiffness, high wear resistance, low density, low thermal expansion coefficient, and aluminum-based silicon carbide has very good dimensional stability, good electrical conductivity and thermal conductivity and wear resistance and fatigue resistance. This material has been widely used in aerospace, automobile, weapon and other fields and has made great contributions to the development.

The machining problems of aluminum-based silicon carbide and the needs of high-efficiency and precision machining of model products, the use of CNC machine tools in the roughing stage to improve the material removal rate, arc milling can be used to achieve high-efficiency roughing; aluminum-based silicon carbide is in the finishing process.

In the first stage, the goal is to reduce the cutting force and avoid surface defects, and then for aluminum-based silicon carbide with different volume fractions, milling and traditional CNC milling are used to achieve precision machining.

Aluminum-based silicon carbide fully satisfies the requirements of lightweight packaging and its high-density communication. Aluminum-based silicon carbide is mainly suitable for applications in aviation, aerospace, electronics, high-speed rail and microwave fields. The material of choice for management issues, aluminum-based silicon carbide has fully demonstrated that the aerospace industry will be widely used in future development.

As a professional manufacturer of aluminum-based silicon carbide, Be-Cu Ceramics has complete machining equipment and first-class machining technology. At the same time, it has developed new machining methods, which can effectively improve product quality and product demand.

About China Advanced Ceramic CNC Machining Company - Be-Cu

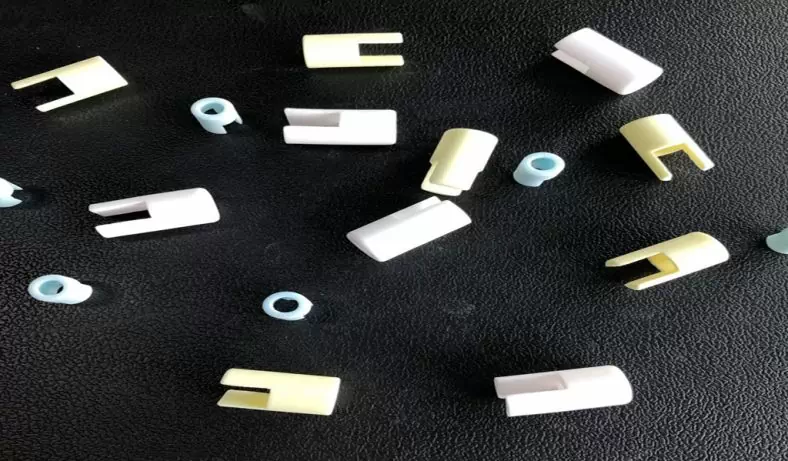

Manufacturer of precision machined components. Ceramic cnc machining components include high dielectric strength, electrical & corrosion resistance, & non-porous & non-shrinking properties.Manufacturer of high temperature fabricated and machinable ceramics including alumina, glass-ceramic, alumino-silicate, boron nitride and zirconium phosphate. Adhesives, coatings and potting compounds to 3200 degrees F,Air firing services for ceramics up to 1650 degrees C also available. Products include insulators, guides, washers, tubes, blocks, & rods for thermal, electrical, corrosion exposure, structural, wear, & semi-conductor operations. Services include machining to tolerances of +/- .0001, ultrasonic core drilling, centerless grinding, milling, & ID & OD threading.Surface grinding, dicing, OD (outer dia.) grinding, ID (inner dia.) grinding, centerless grinding, hole drilling, jig grinding, lapping, honing & polishing service are also available. Diamond grinding with dimensional tolerances of 5 microns & surface finishes of 0.2 microns (8 micro-in.) can be performed.Blanket orders and AutoCAD files & other 3d files accepted.Contact us for your machining ceramic project!

-

Metal Plating ZrO2 Zirconia Ceramic Parts

-

ZrO2 Structural Ceramic Semiconductor Parts

-

Alumina Ceramic Screw Type Parts

-

Cnc Machining Alumina Ceramic Screw Heating Pipe

-

Brushed Fishing Tackle Alumina Ceramic Accessories

-

Winding Machine Alumina Ceramic Wire Wheel

-

Insulation Device Microcrystalline Ceramic Multi-Slot Ceramic Column

-

99 Alumina Ceramic Spool Insulator Sleeve

-

The Alumina Ceramic Ring Of Textile Machine Thread Passing Wheel

-

Isostatic Pressure Insulation Alumina Ceramic Column