The composition of the Simodrive 611UE feed servo system. CNC lathe mainly includes power module, power module, control module, filter module, reactor, motor and so on.

Power Module

The power supply module provides the power supply of the servo drive system, including the weak current for maintaining the normal operation of the system and the 600V DC voltage for supplying the power module.The interfaces and signals on the power module are as follows:

- Ul, Vl. Wl: three-phase power input port of the main control circuit.

- X181: 2U1, 2VI. 2W1 is the input port of the working power supply, and is often short-circuited with the main power supply ports 1U1, 1V1, 1W1.

- Control enable input. This signal is valid for all connected control modules at the same time. When the signal is canceled, the speed given voltage of all axes is zero, and the axes stop at the maximum acceleration. After a certain delay, the Pulse enable canceled.

- 63: Pulse enable input terminal. The signal of CNC lathe is valid for all connected control modules at the same time. After the signal is canceled, the driving power of all control motors is canceled, and the axis stops in the form of free movement.

- 48: Contactor enable input. When the signal is disconnected, the contactor that controls the power supply of the main circuit is disconnected.

- Xlll: The driver is ready for the output terminal. Between 74. 73.2 terminals are NC contacts, and between 72. 73. 1 terminals are NO contacts. After the CNC lathe driver is powered on, if the module is not faulty, the 72.73.1 terminal is connected; if the module is faulty, the 72 and 731 terminals are disconnected.

- X121: drive and motor overheat alarm terminal. Overloading of all modules and overheating of connected motors will trigger the overtemperature alarm output. 51. The NO contact is between the 52 terminals, and the NC contact is between the 51 and 53 terminals.

- 9/19/R: 9 is the enable voltage output terminal, +24V; 19 is the reference ground terminal of the enable voltage; R is the alarm reset input terminal of the module.

- X351: Device bus. The CNC lathe provides working power and so on for the modules connected behind.

The enabling conditions for the normal operation of the CNC lathe power module: terminals 48, 63, 64, and 112 are connected to +24V high level (terminal 9), and the NS1 and NS2 terminals are short-circuited. 63, 64, 48 enable signal power-on and power-off sequence.

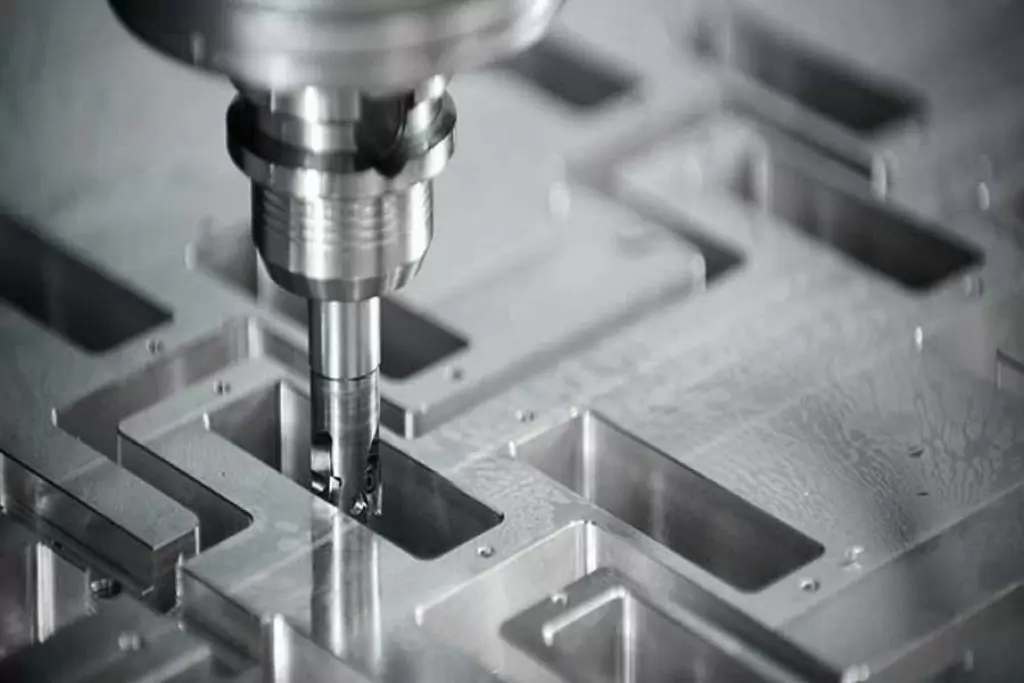

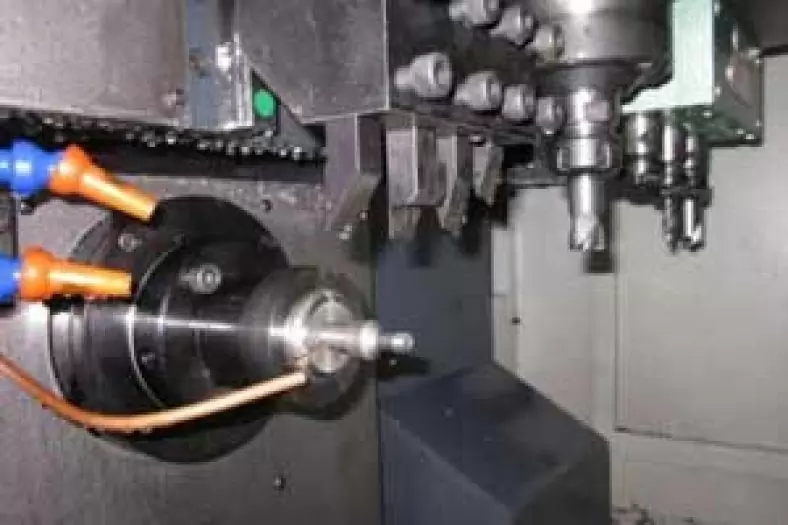

The Detail Of BE-CU cnc machining Shop

BE-CU.COM – As an accomplished CNC machining Service Manufacturer and CNC shop, BE-CU Prototype has been specialized in OEM CNC lathing, custom CNC machining parts production and rapid CNC machining services China for over 35 years and always maintaining the highest standard in delivery speed and reliable quality of precision CNC manufacturing components. With the help of high-level technology and efficient equipment, as well as rigorous attitude, BE-CU passed the ISO9001:2015 quality certification, which supports the long-term development of CNC milling services, CNC turning services, CNC milling-turning, CNC drilling services, 3/4/5 axis machining, gear machining services, CNC machining China custom parts and service, small parts machining, etc.Our CNC machining products can be utilized in a broad range of industries. Contact us for email: [email protected]