GSK 980T CNC system is a widely used CNC system manufactured by GSK CNC Equipment Co., Ltd. in China. It is essential to note that the specific system signals and diagnostics for GSK 980T CNC may vary based on the version, configuration, and software installed.

The system signal of GSK 980T CNC system diagnosis platform includes the following contents:

- 10 digital input signals: X1 to X10.

- 10 digital output signals: Y1 to Y10.

- 1 analog output signal: M.

- 3 encoder signals: Z1 to Z3.

- 1 battery signal: BAT.

These signals can be used to detect and control the working status and fault diagnosis of GSK 980T CNC system. For example, digital input signals can be used to detect the status of external devices, digital output signals can be used to control external devices, and analog output signals can be used to control the operating speed or position of devices, etc. The encoder signal can be used to detect the motion status of the device, the battery signal can be used to detect the battery power status, etc.

System Interface Signal

- Diagnostic table.

- Signal meaning.

- PCX, PCZ: the zero point signal of the corresponding axis.

- RFX, RFZ: The reference counter of the corresponding axis is zero.

- ALMX, ALMZ: The driver alarm of the corresponding axis.

The 2-bit diagnostic information corresponds to the ALM of the hardware circuit. Among them, X and Z represent the X-axis and Z-axis. The ALMZ and ALMX bits of the machine tool system parameter Nu009 are related to the effective level of this signal.

If the ALMX bit of the No. 9 parameter is set to “1”, the system will generate a driver alarm of the corresponding axis when AIMX is “0”. On the contrary, when AIMX is “1”, the system will generate a driver alarm of the corresponding axis. If the driver used cannot provide this signal, do not connect this signal when making the cable, and set the ALMZ and ALMX bits of parameter Ng009 to “.”. When a driver alarm occurs, it is necessary to determine whether the fault is on the CNC system side or the driver side. ,

- OIO, hand-crank data.

- PCS, the signal for one revolution of the spindle position encoder.

No Alarm Occurs And The Motor Does Not Move

- The system position display does not change: Check whether the system information is normal.

- Change of system position display: First check whether the machine tool is locked. When the machine tool is locked, the display of machine coordinates will not change, and it must be ensured that this display changes.

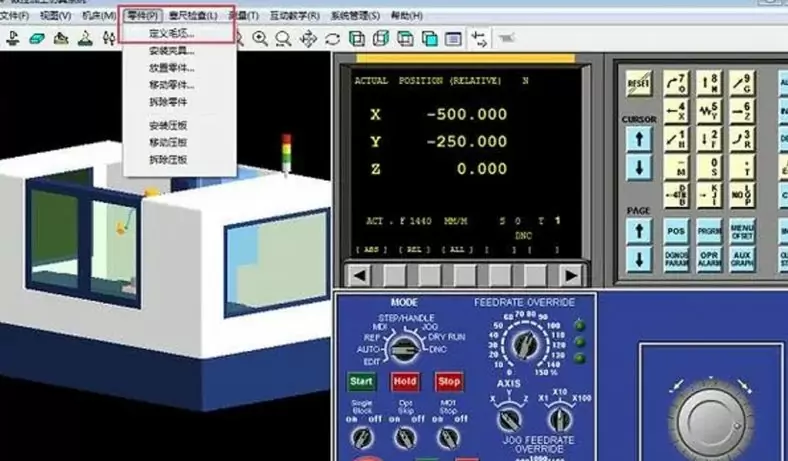

MDI Operation Panel Keys

N0016~022: Keyboard key diagnosis.

Ng024-029, machine tool operation panel key diagnosis.

When the cursor is under these diagnostic numbers, the detailed content display line at the bottom of the LCD has the detailed display of the corresponding key in the line.

When the corresponding key is pressed in the MDI operation panel of the machine tool, the corresponding bit will display “1”, and after the key is released, it will display “0”, otherwise it indicates that a fault has occurred.

CNC Input, Output Signal

This part of the signal is the signal transmitted between the PMC and the CNC within the CNC, which is used to understand the working state of the CNC, and has no direct connection with the hardware circuit.

At Be-cu.com,we use advanced equipment to offer you Unparalleled precision for producing metal and plastic machining parts

- We combine the latest CNC milling and turning processes with proprietary technology to deliver high quality, on-demand parts.

- Our team of engineers and machinists program the equipment to optimize cutting time, surface finish, and final tolerance to meet your design specifications

- We specialize in cnc precision machining, single part prototyping, short to medium production runs, manufacture parts on time, every time, so you can stay ahead of schedule

- CNC machining can create very similar parts to series parts. It is often more efficient and faster than other rapid prototyping technologies for the manufacture of a quantity of prototypes between 1 and 10 parts . We also recommend CNC machining for parts with large sizes (greater than 600 mm).

Contact Us ([email protected]) Now for your Custom CNC Machining, We are your best online cnc machining and rapid prototyping services choice!