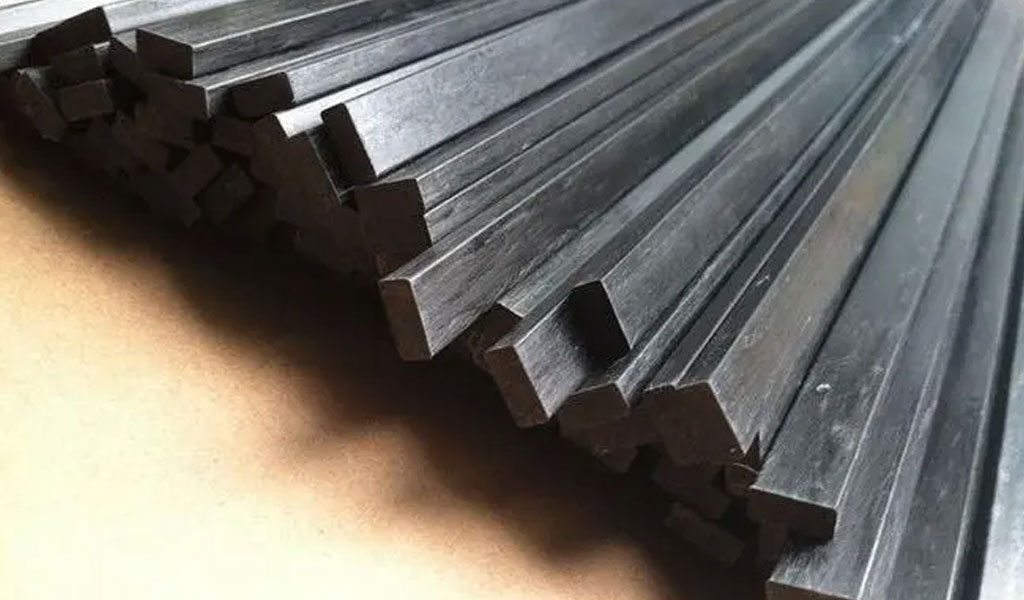

Carbon fiber is a high-performance structural material with a series of performance advantages such as light weight, high strength, corrosion resistance, aging resistance, and high working temperature. In practical applications, it is often combined with resin and other matrix materials to form carbon fiber composite materials. Carbon fiber products have been used in many fields. In this article, let’s take a look at the molding of carbon fiber products.

First, the mold needs to be cleaned to ensure the quality of the product, and then a layer of release agent is applied on the surface of the mold to facilitate the release of subsequent products, and then the prepreg is laid in the mold to ensure that each layer of prepreg The material is compacted.

After all the prepreg layers are completed, the mold is closed, and in order to remove the air in the mold, after the mold manufacturing is closed, some need to open the mold for a period of time to ensure that the material has not yet cured.

The process in which the material changes from a fluid state to a hard infusible insoluble state is called the curing of thermosetting resins. The speed of curing depends on the rate at which the composition of low relative molecular mass in the resin is converted to the product of high relative molecular mass, that is, the curing speed is related to the molecular structure of the resin. After the solidification is completed, it is necessary to hold the pressure for a certain period of time, and after cooling, the mold release treatment is performed.

Composite material molding process methods mainly include hand lay-up, injection, winding, vacuum diversion, molding, autoclave, soft mold, resin transfer molding, etc. The composite material molding process is an important part of it and usually includes two stages. First, the raw materials are deformed or flowed under a certain temperature and pressure to obtain the required shape, and then try to maintain its shape. This article briefly describes the characteristics and molding process of the carbon fiber robotic arm molding process.

Molding Process Characteristics

The molding process is to put a certain amount of prepreg into the opposite mold cavity of the metal mold, use a press with a heat source to generate a certain temperature and pressure, and after closing the mold, the prepreg is made under a certain temperature and pressure. A process method in which composite material products are obtained by softening by heat, flowing under pressure, filling and flowing, filling the mold cavity, forming and solidifying in the mold cavity.

Molding Process

The characteristic of the compression injection molding process is that it requires heating during the molding process. The purpose of heating is to soften and flow the resin in the prepreg, fill the mold cavity, and accelerate the curing reaction of the resin matrix material. When the prepreg fills the mold cavity, not only the resin matrix flows, but the reinforcement materials also flow with it. The resin matrix and reinforcing fibers fill all parts of the mold cavity at the same time. Only when the resin matrix has a high viscosity and strong bonding force can it flow together with the reinforcing fibers. Therefore, the molding process requires a large molding pressure, which requires the metal mold to have high strength, high precision and corrosion resistance, and requires a special A hot press is used to control process parameters such as temperature, pressure, holding time, etc. of curing molding.

The difference between compression molding and autoclave molding is that there is no need to put the prepreg blank and the tooling mold into the tank body like in autoclave molding. It has good observability and a large pressure adjustment range, the internal quality of the structure is easy to ensure, and the external dimension accuracy is high. Therefore, it is widely used in the manufacturing of composite structural components with complex shapes. Such as composite engine blade molding.

The compression molding method has high production efficiency, accurate product dimensions, and smooth surfaces. Especially for composite products with complex structures, they can generally be molded in one go without damaging the performance of the composite products. Its main shortcoming is that mold design and manufacturing are relatively complex and the initial investment is large. Despite the above-mentioned shortcomings of the compression molding process, the current mold molding process still occupies an important position in the composite material molding process.

China Be-cu Prototype Material Technology Co., Ltd. has a production workshop of more than 5,000 square meters, which is used for a variety of large-scale equipment, which can meet the needs of customers in the fields of carbon fiber products, medical equipment, rail transit, automobile industry, etc., and is committed to bringing customers Come to high-quality carbon fiber products.

ISO 9001 certified. BE-CU Prototype Offering CNC machining carbon fiber and other manufacturing services for carbon fiber marterial. Various capabilities include notching, labeling, drilling carbon fiber, grinding, laser cutting carbon fiber, finishing, plating, marking, CNC milling carbon fiber and turning carbon fiber.We stock high quality 3k carbon fiber sheet in a variety of thickness, types and finish. Its a great material used in applications where light weight and strength are needed such as drones. Unlike other workshops, we have no min order and are often filling orders with a single part. We also don’t make you pay for the full sheet and you only get charged for what is used. With a large selection of material, you should find everything you need to make your project come to life. We are also able to handle larger production runs and provide a competitive pricing. If we don’t have the material or finish you require, we are more the willing to look at bringing it in for you.

What Is Carbon Fiber?Carbon fiber is made of polyacrylonitrile (PAN) (or pitch, viscose) and other organic fibers by carbonization (removal of most elements except carbon) by pyrolysis method under inert gas at high temperature above 1,000 °C. Inorganic polymer fibers with a carbon content of more than 90%.

-

3D Printing Continuous Fibres

-

3D Printing Short Fibre Filled Wires

-

Laser Cutting Carbon Fiber Positioning Keyboard

-

Cnc Turning Industrial Copper-Aluminum Clad Carbon Fiber Machinery Parts

-

Carbon Fiber Luggage Tag Ornaments

-

Laser Cutting Carbon Fiber Guitar Shape Crafts

-

Laser Cutting Carbon Fiber Drone Rack

-

Cnc Milling Carbon Fiber Finger Buckle