Laser cutting has revolutionized the manufacturing industry by offering an accurate and efficient method for cutting various materials, including capillary tubes. Capillary tubes, known for their small diameters and thin walls, find extensive use in industries such as medical, automotive, aerospace, and electronics. Laser cutting provides a high level of precision required for these delicate components, enabling manufacturers to achieve intricate designs and superior quality products.

What Is Capillary Tubes

Before delving into laser cutting techniques, it’s crucial to comprehend the characteristics of capillary tubes.

Capillary tubes are slender tubes with diameters typically ranging from fractions of a millimeter to a few millimeters. These tubes are commonly made from materials like stainless steel, copper, aluminum, and plastics, featuring thin walls and precise tolerances.

These tubes serve diverse purposes, such as fluid transportation, medical applications like blood analysis, heat exchangers, microfluidics, and more. Due to their small size and intricate structure, precise cutting methods are essential to ensure the tubes’ integrity and functionality.

Laser Cutting Process

Laser cutting involves using a high-powered laser to melt, burn, or vaporize material, resulting in a precise and clean cut. When it comes to capillary tubes, the laser cutting process requires specialized equipment capable of handling small-scale, high-precision tasks.

Equipment and Setup

To start the process, a dedicated laser cutting machine equipped with a suitable laser source, focusing optics, and a computer numerical control (CNC) system is essential. The choice of laser type, whether it’s CO2, fiber, or neodymium-doped yttrium aluminum garnet (Nd:YAG), depends on the material being cut and the desired precision.

The capillary tubes are securely positioned within the cutting machine, ensuring stability and accuracy during the cutting process. Proper fixturing and alignment are crucial to maintain the tubes’ integrity and prevent distortion or damage during cutting.

Parameters and Settings

Setting the appropriate parameters for laser cutting is a critical step. Factors such as laser power, cutting speed, focus depth, and assist gases need to be optimized based on the material properties, thickness, and desired cut quality. Precise calibration of these parameters ensures clean, accurate cuts without compromising the structural integrity of the capillary tubes.

Laser Cutting Techniques

Laser cutting capillary tubes involves various techniques depending on the desired outcome and the tube’s material composition. The two primary methods employed in laser cutting include:

- Percussion Cutting: In this method, the laser rapidly pulses to create localized heating, resulting in precise cuts. Percussion cutting is suitable for thin-walled capillary tubes and allows for high-speed cutting with minimal heat-affected zones.

- Ablative Cutting: Ablative cutting involves continuous-wave laser beams that gradually vaporize or melt the material along the cutting path. This method is ideal for thicker-walled capillary tubes and ensures smooth edges and minimal burring.

- Micro Laser Cutting:Micro laser cutting is a subset of laser cutting that focuses on extremely small-scale components, such as capillary tubes. These tubes, often utilized in industries like medical, electronics, aerospace, and microfluidics, require cutting with utmost precision due to their minute size and critical functions.

Applications and Benefits

The precision offered by laser cutting technology opens doors to various applications for capillary tubes across industries. These applications include:

- Medical Devices: Capillary tubes used in microfluidics, blood analysis, and diagnostic devices benefit from the high precision of laser cutting, ensuring accuracy in fluid flow and analysis.

- Electronics: Capillary tubes in electronic components and sensors require intricate designs, and laser cutting enables the production of precise, custom shapes.

- Aerospace and Automotive: Fuel injection systems, airbags, and cooling systems often utilize capillary tubes, and laser cutting ensures their accuracy and reliability.

The Benefits Of Laser Cutting Capillary Tubes Include

- High Precision: Laser cutting offers exceptional accuracy, enabling intricate designs and tight tolerances, crucial for capillary tubes’ functionality.

- Minimal Material Waste: The precision of laser cutting minimizes material waste, optimizing resource utilization and reducing production costs.

- Versatility: Laser cutting machines can handle various materials, allowing manufacturers to work with different types of capillary tubes efficiently.

Challenges and Considerations

While laser cutting offers numerous advantages, it also presents challenges, especially when dealing with capillary tubes:

- Heat-Affected Zone: Excessive heat during cutting can cause deformation or alterations in the tube’s properties, affecting its functionality.

- Material Compatibility: Different materials react differently to laser cutting, requiring adjustments in parameters and techniques.

- Precision and Fragility: Maintaining the structural integrity of capillary tubes during cutting while achieving precise dimensions can be challenging due to their delicate nature.

Safety Measures

Ensuring safety during laser cutting operations is paramount. Safety precautions include:

- Proper Ventilation: Adequate ventilation systems to remove fumes and gases produced during cutting.

- Eye Protection: Use of appropriate laser safety goggles to protect against harmful radiation.

- Training and Maintenance: Regular training for operators and maintenance of equipment to prevent accidents and ensure proper functioning.

Conclusion

Laser cutting technology has significantly transformed the manufacturing landscape, particularly in precision cutting of capillary tubes. Its ability to offer high accuracy, versatility, and efficiency makes it a preferred method in various industries.

Understanding the intricacies involved in laser cutting capillary tubes, optimizing parameters, addressing challenges, and prioritizing safety measures are crucial for manufacturers to harness the full potential of this cutting-edge technology in producing high-quality capillary tube cut components for diverse applications.

The Detail Of BE-CU Laser Cutting Company

BE-CU.COM Laser Cutting provides services to a wide network of industries and markets. BE-CU is uniquely positioned to Laser Cut, Laser Engrave, Precision CNC Machine and Precision Finish Grind parts and components.We use large format industrial laser cutting machines that are extremely precise with up to .001” tolerance. Not only we cut and engrave your project, we are ready to answer any questions you may have about the process and give you expert advice.

So, reach out even if you’re unsure of your specific need or if you think you may require a different type of manufacturing service(as laser cutting medical parts). Laser cutting service by BE-CU makes ordering your parts simple. Just upload your CAD files onto the platform for an instant price and lead time. Our mission is to save engineers’ time for value-adding activities.

-

Etching LED EMC Packaging Bracket

-

Etching Low Resistivity Copper 110 Contact Rings

-

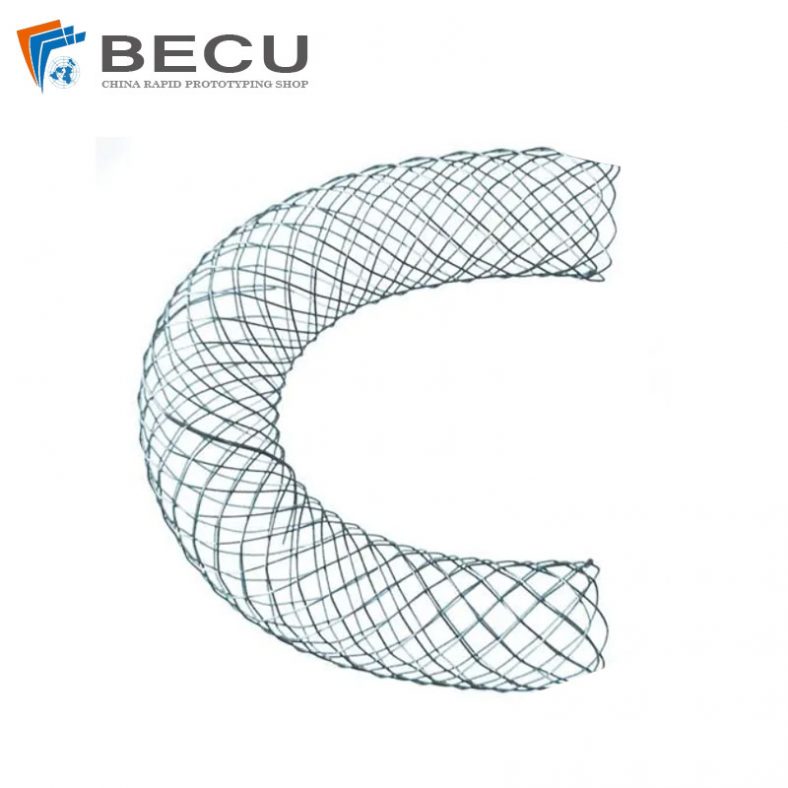

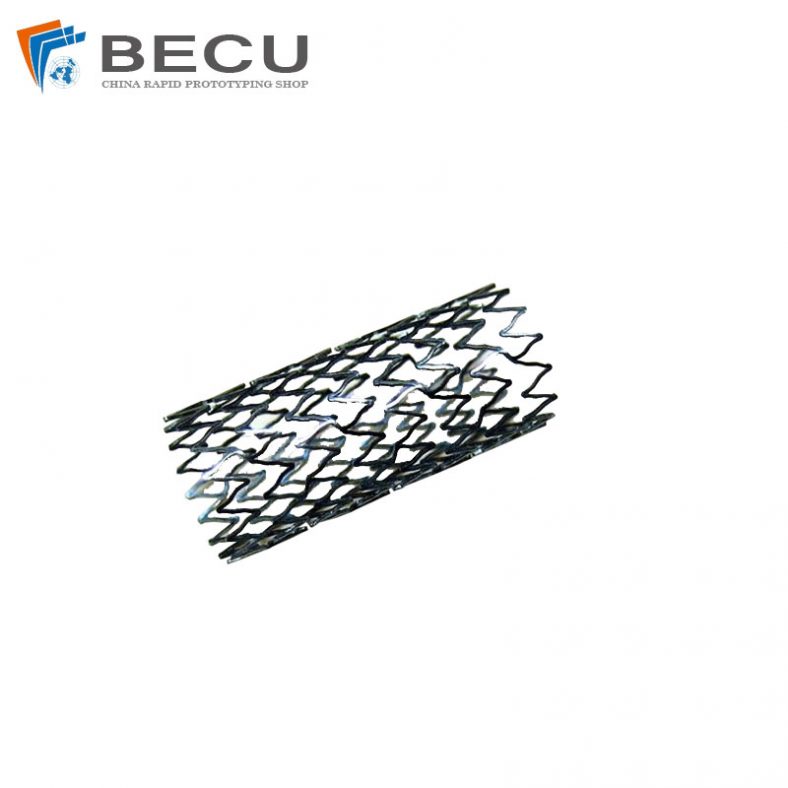

Laser Cut Nitinol Stent For Bile Duct

-

Stents For Carrying Valves And Venous Valve Replacement Devices

-

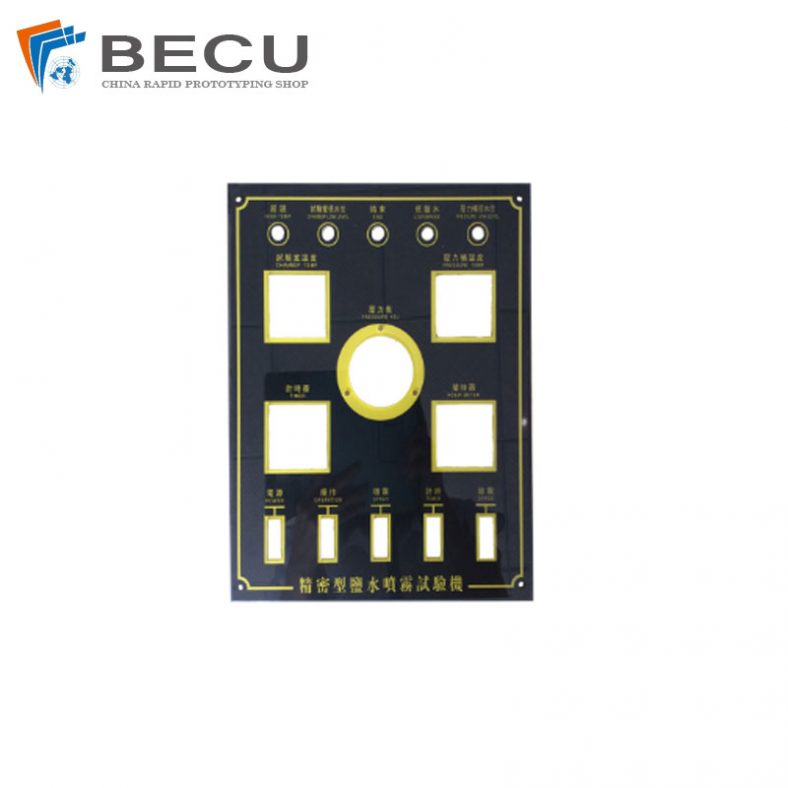

Laser Cutting PC Anti-Static Membrane Switch

-

Precision Engraving Special-Shaped Natural Color PEEK Parts

-

Acrylic Laser Cut Signs

-

Acrylic Laser Cut Earrings