Aluminum nitride ceramic substrate has excellent thermal conductivity (5-10 times that of alumina self-ceramic), low dielectric constant and dielectric loss, reliable insulation performance, excellent mechanical properties, non-toxic, high temperature resistance, It is resistant to chemical corrosion and has a thermal expansion coefficient similar to that of silicon. It is widely used in sub-communication devices, high-brightness LEDs, power electronic devices and other industries.

Aluminum nitride ceramic heat sinks have emerged as crucial components in various industries, including electronics, automotive, aerospace, and more. Their exceptional thermal conductivity, electrical insulation properties, and mechanical strength make them indispensable for dissipating heat efficiently. However, machining aluminum nitride ceramics presents unique challenges due to their hardness and brittleness. In this comprehensive guide, we delve into the machining methods of aluminum nitride ceramic heat sinks, exploring techniques, tools, considerations, and best practices to achieve optimal results.

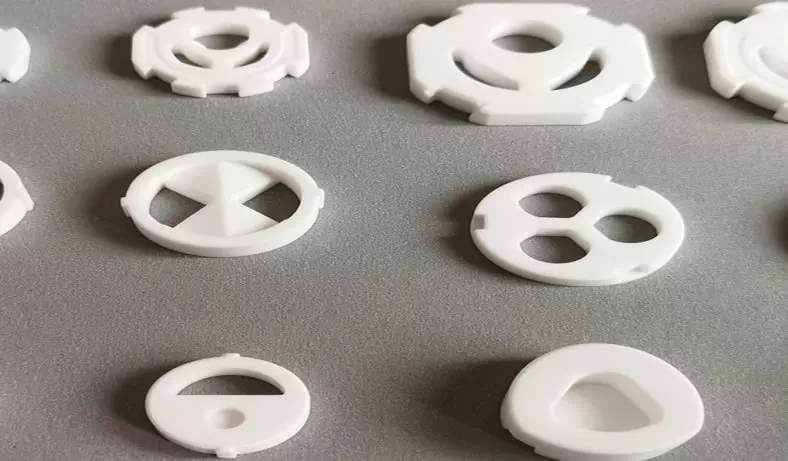

Aluminum Nitride Ceramic Machining Form

- According to customer requirements, the surface can be metallized with gold plating, silver plating, copper plating and other metals, and its thermal conductivity is better.

- Conventional ceramic products can be polished (single and double-sided polishing can be performed). The surface finish after polishing is Ra: 0.02-0.05μm, and there is no hole phenomenon.

- Other machining methods can be processed according to the customer’s drawing requirements.

Processing Form Of Aluminum Nitride Ceramic Products:

- Mould-opening machining: All products except laser machining require mould-opening machining.

- Laser machining products: according to customer requirements, laser products (aluminum nitride, alumina, aluminum nitride, etc.) are used for scribing, drilling and slotting machining. The minimum diameter of laser drilling is 0.05mm, and the thickness of laser cutting is less than 2mm. , its products have high machining precision and good repeatability.

Understanding Aluminum Nitride Ceramic

Aluminum nitride (AlN) ceramic is a high-performance material with excellent thermal conductivity properties, second only to diamond among ceramics. Its unique combination of thermal, electrical, and mechanical properties makes it an ideal choice for heat sink applications. AlN ceramics exhibit high thermal stability, chemical inertness, and low thermal expansion coefficients, ensuring reliable performance in demanding environments.

Challenges in Machining Aluminum Nitride Ceramic

Machining aluminum nitride ceramic presents several challenges due to its inherent properties:

- Hardness: Aluminum nitride ceramic ranks high on the Mohs scale of hardness, making it difficult to machine using conventional methods.

- Brittleness: AlN ceramics are brittle materials prone to cracking and chipping, requiring careful handling during machining processes.

- Abrasiveness: The abrasive nature of aluminum nitride can cause rapid tool wear and affect machining accuracy and surface finish.

- Thermal Conductivity: While beneficial for heat dissipation, the high thermal conductivity of AlN ceramics can lead to heat buildup during machining, exacerbating tool wear and material deformation.

Machining Methods for Aluminum Nitride Ceramic Heat Sinks

Several machining methods are employed to fabricate aluminum nitride ceramic heat sinks, each with its advantages, limitations, and specific applications:

Diamond Grinding

Diamond grinding is a widely used method for machining hard and brittle materials like aluminum nitride ceramic. This process involves using diamond abrasive wheels to remove material gradually and achieve precise dimensions and surface finishes. Diamond grinding offers high material removal rates and excellent dimensional accuracy but requires coolant to mitigate heat buildup and prevent thermal damage to the workpiece.

Laser Machining

Laser machining utilizes high-energy laser beams to vaporize or melt material from the workpiece, enabling precise shaping and intricate detailing of aluminum nitride ceramic heat sinks. Laser machining offers non-contact processing, minimal tool wear, and high flexibility for complex geometries. However, it may induce thermal stress and micro-cracking in the workpiece, requiring careful control of process parameters and cooling systems.

Electrical Discharge Machining (EDM)

EDM is a thermal machining process that utilizes electrical discharges to erode material from the workpiece. In EDM, a series of electrical pulses between the tool (electrode) and the workpiece generate localized melting and vaporization, facilitating material removal. EDM is suitable for machining intricate shapes and hardened materials like aluminum nitride ceramic, with minimal mechanical stress and excellent dimensional accuracy. However, it may produce recast layers and surface roughness, necessitating post-processing steps for surface finishing.

Ultrasonic Machining (USM)

Ultrasonic machining employs high-frequency vibrations transmitted to a tool, which, in turn, induces abrasive particles to remove material from the workpiece. USM is effective for machining brittle materials like aluminum nitride ceramic, offering precise control over material removal rates and surface finishes. However, it may result in tool wear and require frequent abrasive replenishment to maintain machining efficiency.

Considerations for Machining Aluminum Nitride Ceramic Heat Sinks

When machining aluminum nitride ceramic heat sinks, several considerations must be taken into account to ensure optimal results:

- Tool Selection: Choose cutting tools with high hardness, wear resistance, and thermal stability, such as diamond or cubic boron nitride (CBN) tools, to withstand the abrasive nature of AlN ceramics.

- Coolant Strategy: Implement effective coolant systems to dissipate heat generated during machining and prevent thermal damage to the workpiece and cutting tools. Consider using water-based coolants or compressed air for efficient heat removal.

- Machining Parameters: Optimize cutting parameters, including cutting speed, feed rate, and depth of cut, to minimize tool wear, heat buildup, and material deformation. Conduct thorough experimentation and process optimization to identify the ideal machining conditions for aluminum nitride ceramic.

- Workpiece Fixturing: Secure the workpiece firmly during machining to prevent vibrations, distortions, and workpiece dislocation. Utilize custom fixtures or clamping systems designed for brittle materials to ensure stability and precision throughout the machining process.

- Post-Processing and Inspection: Perform post-processing steps such as deburring, surface polishing, and dimensional inspection to refine surface finishes and ensure dimensional accuracy of machined aluminum nitride ceramic heat sinks. Employ advanced metrology techniques, including coordinate measuring machines (CMM) and optical profilometers, to verify part quality and adherence to specifications.

Best Practices for Machining Aluminum Nitride Ceramic Heat Sinks

To achieve optimal results when machining aluminum nitride ceramic heat sinks, adhere to the following best practices:

- Conduct thorough material characterization and analysis to understand the properties and behavior of aluminum nitride ceramic, guiding the selection of appropriate machining methods and parameters.

- Invest in high-quality machining equipment, cutting tools, and coolant systems capable of handling the challenges posed by machining hard and brittle materials like AlN ceramics.

- Prioritize operator training and skill development to ensure safe and efficient operation of machining equipment and adherence to best practices for machining aluminum nitride ceramic heat sinks.

- Implement rigorous quality control measures throughout the machining process, including in-process monitoring, inspection, and documentation, to uphold part quality and consistency.

- Foster collaboration and knowledge exchange among machining experts, materials scientists, and engineers to explore innovative techniques and solutions for enhancing the machining of aluminum nitride ceramic heat sinks.

Conclusion

Mastering the machining method of aluminum nitride ceramic heat sinks is essential for unlocking their full potential in various industrial applications requiring efficient heat dissipation. By understanding the unique properties of aluminum nitride ceramic and employing appropriate machining methods, tools, and best practices, manufacturers can fabricate high-quality heat sinks with precise dimensions, superior thermal performance, and exceptional reliability. Continuous research, innovation, and collaboration across disciplines will drive further advancements in the machining of aluminum nitride ceramic and pave the way for future breakthroughs in thermal management technology.

About China Advanced Ceramic CNC Machining Company - Be-Cu

Manufacturer of precision machined components. Ceramic cnc machining components include high dielectric strength, electrical & corrosion resistance, & non-porous & non-shrinking properties.Manufacturer of high temperature fabricated and machinable ceramics including alumina, glass-ceramic, alumino-silicate, boron nitride and zirconium phosphate. Adhesives, coatings and potting compounds to 3200 degrees F,Air firing services for ceramics up to 1650 degrees C also available. Products include insulators, guides, washers, tubes, blocks, & rods for thermal, electrical, corrosion exposure, structural, wear, & semi-conductor operations. Services include machining to tolerances of +/- .0001, ultrasonic core drilling, centerless grinding, milling, & ID & OD threading.Surface grinding, dicing, OD (outer dia.) grinding, ID (inner dia.) grinding, centerless grinding, hole drilling, jig grinding, lapping, honing & polishing service are also available. Diamond grinding with dimensional tolerances of 5 microns & surface finishes of 0.2 microns (8 micro-in.) can be performed.Blanket orders and AutoCAD files & other 3d files accepted.Contact us for your machining ceramic project!

-

Metal Plating ZrO2 Zirconia Ceramic Parts

-

ZrO2 Structural Ceramic Semiconductor Parts

-

Alumina Ceramic Screw Type Parts

-

Cnc Machining Alumina Ceramic Screw Heating Pipe

-

Brushed Fishing Tackle Alumina Ceramic Accessories

-

Winding Machine Alumina Ceramic Wire Wheel

-

Insulation Device Microcrystalline Ceramic Multi-Slot Ceramic Column

-

99 Alumina Ceramic Spool Insulator Sleeve

-

The Alumina Ceramic Ring Of Textile Machine Thread Passing Wheel

-

Isostatic Pressure Insulation Alumina Ceramic Column