Non-destructive testing is to carry out activities such as measurement and detection without destroying the object to be detected. It is the most widely used in the field of metal materials and is relatively mature. Commonly used testing methods include radiographic testing, ultrasonic testing, magnetic particle testing, and penetration testing. , eddy current testing and other methods.

View More New Post:

Because carbon fiber is widely used in military and other fields, the performance requirements of carbon fiber composite materials are extremely high, and excessive delamination and inclusion defects are not allowed inside. Therefore, the detection of carbon fiber composite materials is particularly important. The non-destructive testing methods that can be applied to the defect detection of carbon fiber composite materials mainly include:

Ultrasonic Testing

The method widely used in material defect detection is a relatively early detection method. It is detected by the influence of the material itself or the acoustic properties of defects on the propagation of ultrasonic waves.

It can also be divided into pulse reflection method, pulse transmission method and resonance method. , multiple reflection method, phase reflection method, sound spectrum analysis method, etc.

Radiography

It is based on the different absorption coefficients of different composite materials for radiation or the difference in the composition and shape of the surface and interior of the same composite material, resulting in different attenuation of incident radiation intensity. defect.

Acoustic Emission Detection Method

In the process of applying load to the inspected composite component, the stress of the component will cause the expansion of the original defect or the generation of new defects in the original poor quality area. The expansion of the original defect and the expansion of the sexual defect both generate acoustic signals. Monitor the entire component.

Industrial CT Detection Method

Mainly used in non-destructive testing of three-phase braided composite materials and puncture composite materials in composite materials. It can accurately detect various defects such as metal inclusions, fiber breakage, and insufficient dipping.

Laser Holography Nondestructive Testing

After a certain load is applied to the tested composite component, the displacement change of the component surface is related to the internal defects of the material and the stress distribution of the component. This method can well detect the debonding defects of the bonding interface. Other possible detection methods include: neutron imaging, thermal infrared imaging, microwave detection, penetrant detection, etc.

The use of these advanced technologies and equipment has made the non-destructive testing technology far beyond the connotation of the original testing technology. Carbon fiber composite materials are also widely used in the lightening and high temperature resistance of missile weapons. The carbon fiber produced by China Be-cu Prototype Material Technology Co., Ltd. adopts the PAN yarn of Japan’s Toray Company, which meets the needs of the high-end market and can be used in medical equipment, military protection, sports equipment and other fields. If you have this requirement, please click the online customer service on the right to contact us online.

ISO 9001 certified. BE-CU Prototype Offering CNC machining carbon fiber and other manufacturing services for carbon fiber marterial. Various capabilities include notching, labeling, drilling carbon fiber, grinding, laser cutting carbon fiber, finishing, plating, marking, CNC milling carbon fiber and turning carbon fiber.We stock high quality 3k carbon fiber sheet in a variety of thickness, types and finish. Its a great material used in applications where light weight and strength are needed such as drones. Unlike other workshops, we have no min order and are often filling orders with a single part. We also don’t make you pay for the full sheet and you only get charged for what is used. With a large selection of material, you should find everything you need to make your project come to life. We are also able to handle larger production runs and provide a competitive pricing. If we don’t have the material or finish you require, we are more the willing to look at bringing it in for you.

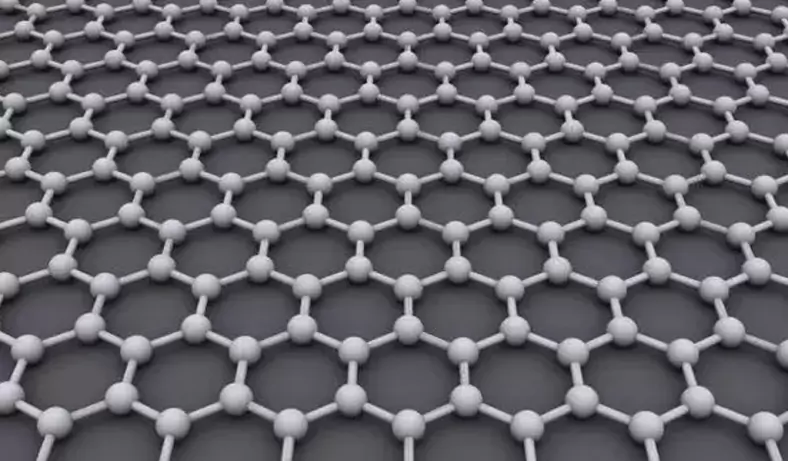

What Is Carbon Fiber?Carbon fiber is made of polyacrylonitrile (PAN) (or pitch, viscose) and other organic fibers by carbonization (removal of most elements except carbon) by pyrolysis method under inert gas at high temperature above 1,000 °C. Inorganic polymer fibers with a carbon content of more than 90%.

-

3D Printing Continuous Fibres

-

3D Printing Short Fibre Filled Wires

-

Laser Cutting Carbon Fiber Positioning Keyboard

-

Cnc Turning Industrial Copper-Aluminum Clad Carbon Fiber Machinery Parts

-

Carbon Fiber Luggage Tag Ornaments

-

Laser Cutting Carbon Fiber Guitar Shape Crafts

-

Laser Cutting Carbon Fiber Drone Rack

-

Cnc Milling Carbon Fiber Finger Buckle