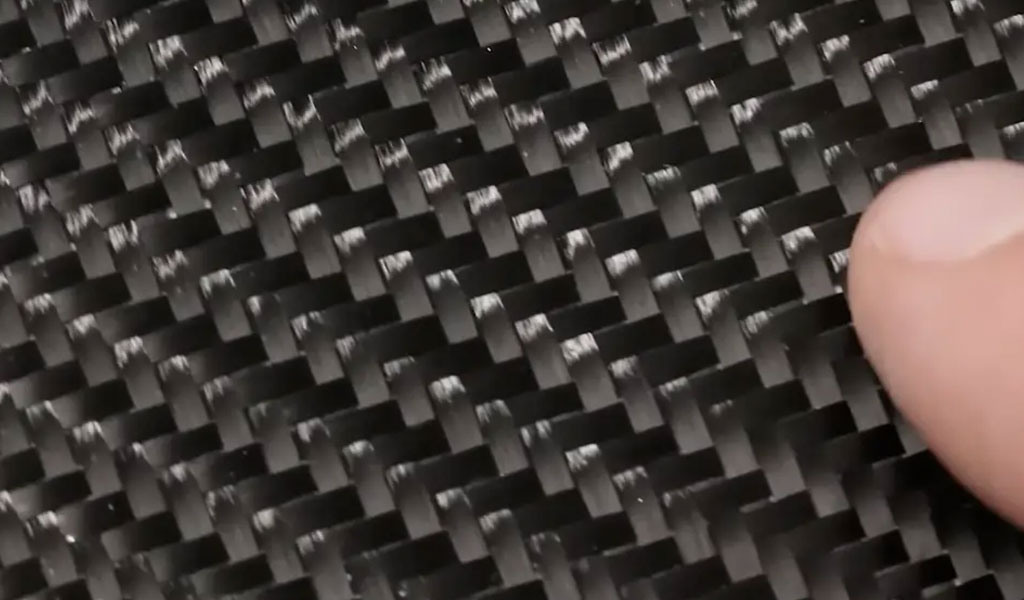

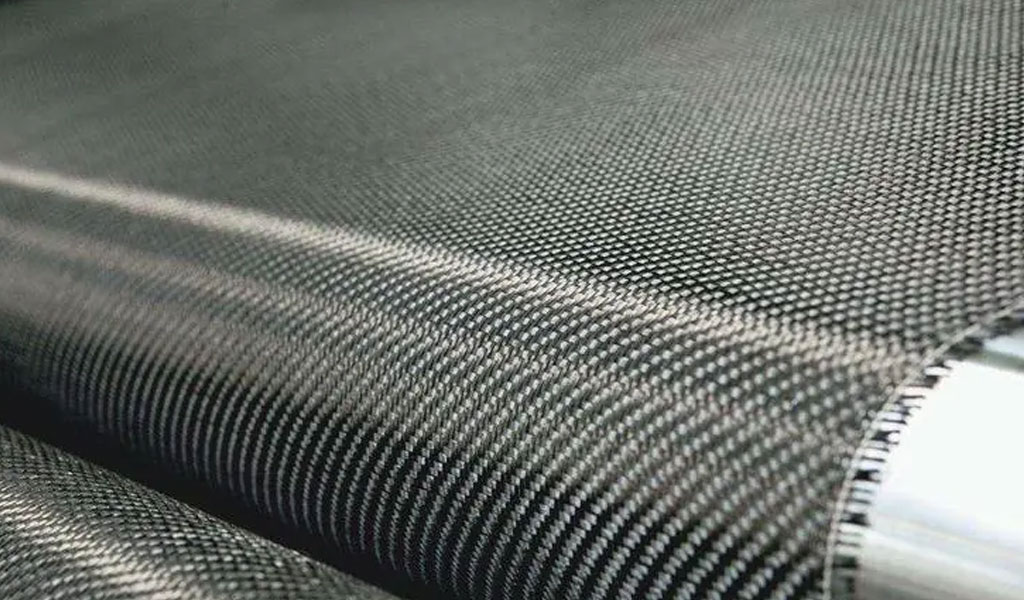

Carbon fiber material is a special fiber material with a carbon content of more than 90%, which is made from polyacrylonitrile (PAN), asphalt, viscose fiber, etc. through pre-oxidation, carbonization, and graphitization processes.

It is composed of flake graphite microcrystalline fibers stacked along the axial direction. It has excellent physical and chemical properties such as small specific gravity, high specific strength, high specific modulus, high temperature resistance, corrosion resistance, oxidation resistance, electrical and thermal conductivity, etc.The diameter of carbon fiber is usually about 10 μm. The diameter of 7 to 8 carbon fibers arranged together is about the diameter of a hair.

Its tensile strength can reach 4800MPa, which is about 7 to 9 times that of steel, and its specific gravity is only that of steel. One quarter, it can still maintain excellent performance at high temperatures above 3000°C. Due to factors such as its material nature, industrial technology complexity, application field importance and market scale, carbon fiber is called “black gold” or “king of materials”

As a fiber material,It is very slender and easy to be stretched, so a lot of dust will be generated during production and machining. These dusts will not only endanger people’s health, but also cause electrical short-circuits and cause serious consequences. For these problems, people have summarized Here are some ways to deal with it.

You Pay Attention To When Machining Carbon Fiber Products

With the development of society and the advancement of science and technology, people have higher and higher requirements for the performance of materials. Traditional metal materials and non-metal materials can no longer meet people’s material and cultural needs. The birth of new materials has solved the shortcomings of single material performance. The carbon fiber composite materials in the new materials not only have a specific strength that exceeds that of metals, but also have corrosion resistance, lightweight and other properties that metal materials do not have.

Therefore, they are widely used in aviation. Aerospace parts, automobile manufacturing, chemical component production, etc. What do we need to pay attention to during the processing of carbon fiber products? Let’s learn about the points to note when processing carbon fiber parts.

1.Is The Tool Sharp?

People who often cook will definitely feel the same way. When we cut vegetables, if we don’t have a good knife, it will not only be very laborious, but also there will be a feeling of disconnection during the cutting process. The same is true for the processing of carbon fiber products. If the tool is not sharp enough, the carbon fiber cuts will not be smooth enough or even cracked. This is different from chopping vegetables, which can be cut several times, but the carbon fiber parts may be scrapped.

2.Layering Of Carbon Fiber Products

Carbon fiber products generally use a lamination process, which involves cutting the prepared prepreg tapes into appropriate sizes and laying them together according to product requirements. Compaction is carried out to make finished carbon fiber parts. Therefore, delamination may occur when drilling carbon fiber parts. Therefore, the quality of carbon fiber products is very important. During production, between the layers of prepreg tapes Tighter bonding will reduce the occurrence of delamination.

Carbon Fiber Factory Safety Precautions

The carbon fiber carbonization process integrates thermal fluid field dynamics and precision control engineering thermophysics in a very large space. It is a systematic scientific engineering of multiple sciences and technologies. Various changes such as chemical reactions, heat and mass transfer are carried out simultaneously and are interconnected, and the influencing factors are abnormal. complex. During the carbonization process, by controlling the temperature field and stress field and controlling the turbostratic graphite structure during the carbonization process, the quality and performance of carbon fiber can be controlled.

The ventilation system must be kept smooth

The carbon fiber manufacturing process requires the use of high temperatures and toxic chemicals. If the ventilation system is poor or blocked, it will cause the accumulation of harmful substances and increase the health risks of workers. Therefore, keeping the ventilation system open is one of the most important safety measures.

Use personal protective equipment

Suitable personal protective equipment is required when working within a carbon fiber factory. This equipment may include heat-resistant gloves, masks, goggles, protective clothing, etc. Use personal protective equipment to keep workers safe.

Fire prevention measures

Carbon fiber factories often have high-temperature manufacturing or cnc machining processes. Therefore, fire extinguishers and other fire extinguishing equipment are one of the necessary safety equipment. In particular, when working indoors, reliable fire alarm equipment needs to be installed.

Strictly implement operating procedures

Operating procedures are important measures to prevent worker injuries or production interruptions. Therefore, in carbon fiber factories, relevant operating procedures must be strictly implemented to ensure safety during the production process.

Regularly inspect equipment and machines

Failure and damage to work equipment and machinery not only interrupt production but can also lead to worker injuries. Therefore, regularly checking the status of equipment and machines, replacing damaged parts and repairing equipment in a timely manner can reduce the risk of accidents.

In short, with the continuous development of carbon fiber technology and various industries using carbon fiber products to improve the performance and quality of their processes and equipment, safety measures in carbon fiber factories have become more important. Workers must take their own safety seriously and follow all safe operating procedures.

To Prevent The Generation Of Dust

When carbon fiber is processed, some dust is generated that floats in the air. In order to prevent dust hazards, you can use electric vacuum cleaners to keep the air clean.

To Prevent Harm To The Human Body

Fiber can cause allergic reactions. When carbon fiber filaments come into contact with human skin, people with allergies may feel pain or itching. Do not rub hard at this time. If the fiber penetrates deep into the skin, it will cause inflammation. The best treatment is to wash with warm soapy water or tape off the carbon fiber filaments. Special attention should be paid to the protection of the eyes and throat. Those engaged in related work should wear goggles and masks. Once the dust enters the lungs, it cannot be discharged.

To Prevent Electrical Short Circuit

Carbon fiber is a conductor, so when airborne fibers seep into a switch or control device, a short circuit can occur. It is recommended to keep the interior clean and tidy, and collect all the carbon fiber products produced in a box, so that it cannot come into contact with electrical equipment. The above are some common problems and solutions for carbon fiber production. Carbon fiber is not a toxic material, and those who use it should not be afraid. As long as they face it correctly and take protective measures, it will not cause harm to the human body.

Copyright Notice

This article comes from China Rapid Prototype Material Technology Co., Ltd. http://www.be-cu.com/ If you need to reprint and quote, you must keep the link and indicate the source, otherwise, you will be investigated.

ISO 9001 certified. BE-CU Prototype Offering CNC machining carbon fiber and other manufacturing services for carbon fiber marterial. Various capabilities include notching, labeling, drilling carbon fiber, grinding, laser cutting carbon fiber, finishing, plating, marking, CNC milling carbon fiber and turning carbon fiber.We stock high quality 3k carbon fiber sheet in a variety of thickness, types and finish. Its a great material used in applications where light weight and strength are needed such as drones. Unlike other workshops, we have no min order and are often filling orders with a single part. We also don’t make you pay for the full sheet and you only get charged for what is used. With a large selection of material, you should find everything you need to make your project come to life. We are also able to handle larger production runs and provide a competitive pricing. If we don’t have the material or finish you require, we are more the willing to look at bringing it in for you.

What Is Carbon Fiber?Carbon fiber is made of polyacrylonitrile (PAN) (or pitch, viscose) and other organic fibers by carbonization (removal of most elements except carbon) by pyrolysis method under inert gas at high temperature above 1,000 °C. Inorganic polymer fibers with a carbon content of more than 90%.

-

3D Printing Continuous Fibres

-

3D Printing Short Fibre Filled Wires

-

Laser Cutting Carbon Fiber Positioning Keyboard

-

Cnc Turning Industrial Copper-Aluminum Clad Carbon Fiber Machinery Parts

-

Carbon Fiber Luggage Tag Ornaments

-

Laser Cutting Carbon Fiber Guitar Shape Crafts

-

Laser Cutting Carbon Fiber Drone Rack

-

Cnc Milling Carbon Fiber Finger Buckle