Carbon fiber is a lightweight, high-strength material that is widely used in various industries such as aerospace, automotive, sporting goods, and more. It’s composed of thin fibers primarily made of carbon atoms. The process of preparing carbon fiber materials involves several steps:

Precursor Material Selection

Carbon fibers are usually made from precursor materials, which are polymers with a high carbon content. Common precursor materials include polyacrylonitrile (PAN), pitch, and rayon. PAN-based precursors are the most commonly used due to their ability to produce high-performance carbon fibers.

Stabilization

The precursor material is heated in an oxygen-free environment to remove volatile elements and increase its carbon content. This process is called stabilization or carbonization. During stabilization, the precursor undergoes a series of chemical and structural changes, resulting in a material that’s closer in composition to carbon.

Carbonization

After stabilization, the material is further heated to very high temperatures (usually around 1500 to 3000°C) in an inert atmosphere, such as nitrogen. This process is called carbonization or pyrolysis. The remaining non-carbon atoms are driven off, leaving behind a material composed mostly of carbon.

Graphitization (Optional)

Some carbon fibers undergo an additional process called graphitization to increase their crystallinity and improve their mechanical properties. This involves heating the carbonized fibers to even higher temperatures, typically around 2500 to 3000°C, in a controlled environment.

Surface Treatment

The surface of carbon fibers is often treated to enhance their bonding with resin matrices in composite materials. This can involve applying coatings or chemical treatments to improve adhesion and overall performance.

Sizing

Sizing is the application of a protective coating to the carbon fibers to improve their handling, protect against abrasion, and enhance the adhesion between the fibers and the matrix in composite applications.

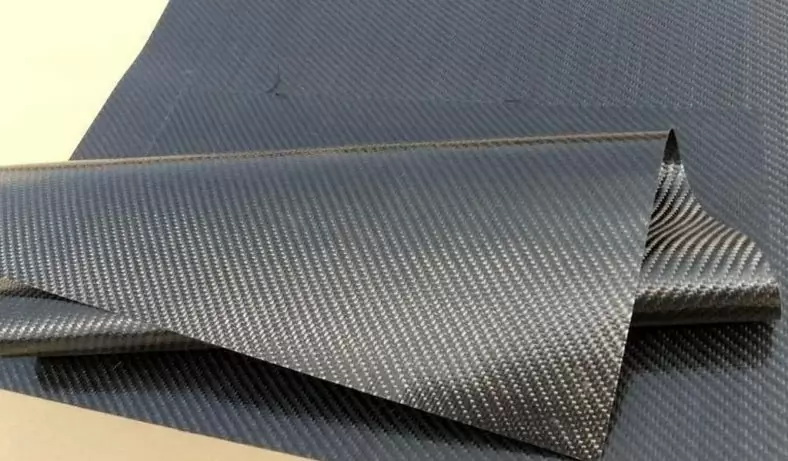

Spooling and Weaving

After the carbon fiber strands are prepared, they can be spooled onto bobbins or woven into fabrics. These fabrics can be in various patterns like plain weave, twill weave, or satin weave, depending on the intended application.

Composite Manufacturing

Carbon fibers are often used as reinforcement in composite materials, where they are combined with a matrix material (usually a polymer resin) to create carbon fiber-reinforced polymers (CFRPs). These composites are used to make various products like aircraft components, automotive parts, sporting goods, and more.

The first carbon fiber in history was made by Edison in 1879 by carbonizing natural cellulose, which was used as electric filament. Since this filament is so easy to break, it has no other use. Since the 1950s, the carbon fiber industry has developed again, and can be made from viscose-based fibers, polyacrylonitrile fibers, and asphalt. Polyacrylonitrile-based carbon fiber is the most used now, because of its high effective utilization rate and good product quality.

Let’s talk aboutcarbon fiber materialpreparation. The preparation of carbon fiber mainly goes through three steps. The first step is called stabilization, that is, the polyacrylonitrile is heated to 300 ℃ with air to cause a cyclization reaction.

The second step is to carbonize the cyclized fibers at 1600°C under the protection of inert gases H2, N2, that is, to remove the volatile components without decomposition and melting.The final step is further machining at high temperatures above 2500°C, while stretching the carbon fibers to transform them into particularly stable graphite fibers. The sublimation temperature of carbon fiber is 3650℃. It has a small thermal expansion coefficient, is corrosion-resistant and is a good electrical conductor.

Another characteristic of such fibers is their high strength. It is often used in combination with resin, military industry, automobile manufacturing, sports equipment and so on. Carbon fiber products are very popular in developed countries such as Europe and the United States. In China, a carbon fiber boom has also been set off in recent years, and the market is gradually expanding. If you need carbon fiber products, please come to our company to buy, our company has carbon fiber board, carbon fiber cloth, carbon fiber tube, carbon fiber auto parts, carbon fiber model aircraft parts, carbon fiber machining parts and other products, with good quality and affordable price, if you buy more, you can get free Go to mold fee.

It’s important to note that the manufacturing of carbon fiber materials is a complex and specialized process that requires careful control of temperature, pressure, and other conditions. The resulting properties of the carbon fibers can be tailored based on the choice of precursor material, processing parameters, and post-treatment techniques.

ISO 9001 certified. BE-CU Prototype Offering CNC machining carbon fiber and other manufacturing services for carbon fiber marterial. Various capabilities include notching, labeling, drilling carbon fiber, grinding, laser cutting carbon fiber, finishing, plating, marking, CNC milling carbon fiber and turning carbon fiber.We stock high quality 3k carbon fiber sheet in a variety of thickness, types and finish. Its a great material used in applications where light weight and strength are needed such as drones. Unlike other workshops, we have no min order and are often filling orders with a single part. We also don’t make you pay for the full sheet and you only get charged for what is used. With a large selection of material, you should find everything you need to make your project come to life. We are also able to handle larger production runs and provide a competitive pricing. If we don’t have the material or finish you require, we are more the willing to look at bringing it in for you.

What Is Carbon Fiber?Carbon fiber is made of polyacrylonitrile (PAN) (or pitch, viscose) and other organic fibers by carbonization (removal of most elements except carbon) by pyrolysis method under inert gas at high temperature above 1,000 °C. Inorganic polymer fibers with a carbon content of more than 90%.

-

3D Printing Continuous Fibres

-

3D Printing Short Fibre Filled Wires

-

Laser Cutting Carbon Fiber Positioning Keyboard

-

Cnc Turning Industrial Copper-Aluminum Clad Carbon Fiber Machinery Parts

-

Carbon Fiber Luggage Tag Ornaments

-

Laser Cutting Carbon Fiber Guitar Shape Crafts

-

Laser Cutting Carbon Fiber Drone Rack

-

Cnc Milling Carbon Fiber Finger Buckle