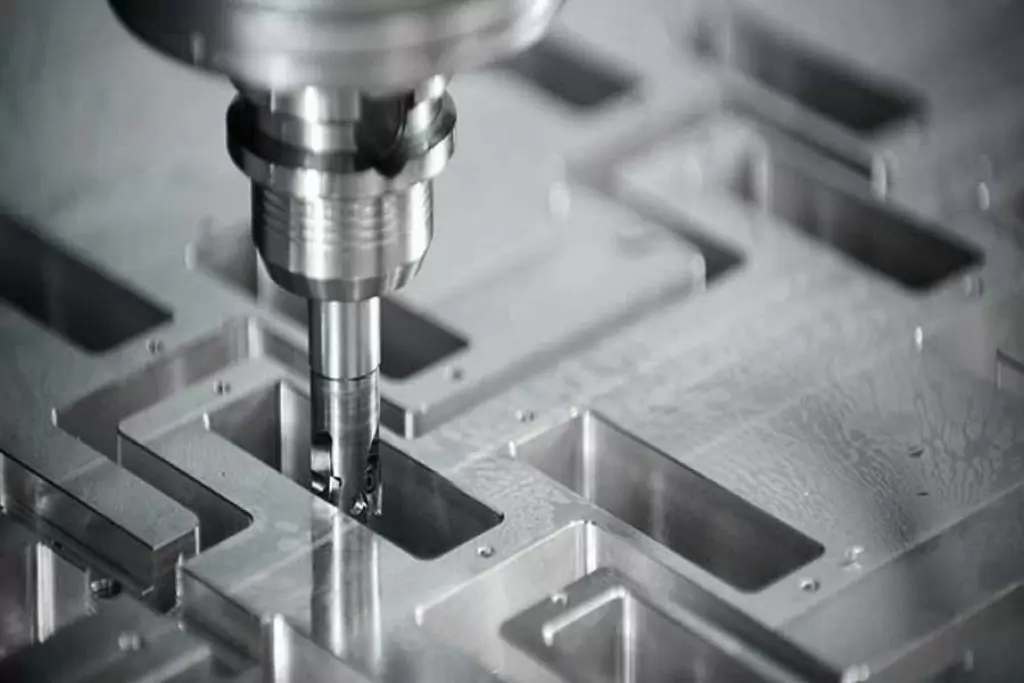

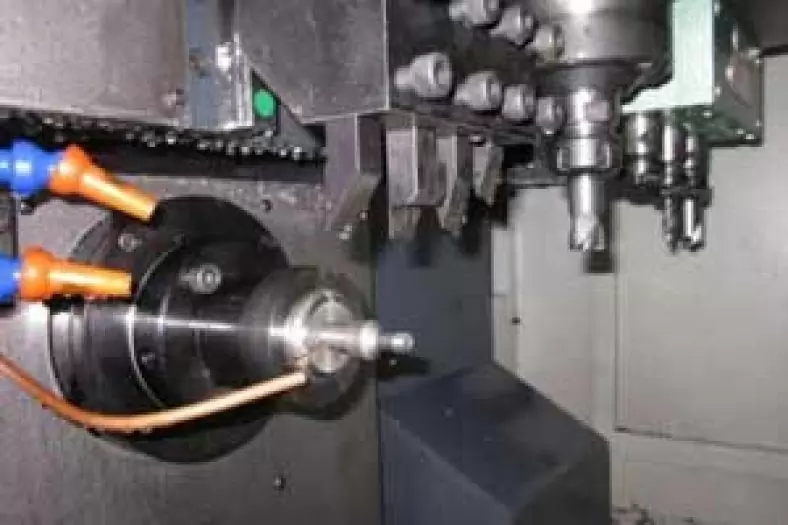

With the development of science and technology, the level of automation and intelligence of modern machinery manufacturing industry is getting higher and higher, and machining centers are increasingly used in production and manufacturing, promoting the development of modern machinery manufacturing industry. CNC machine tools have a high level of automation and intelligence, and the maintenance of China CNC machining centers also has high technical requirements.In daily use, it is not only necessary to strengthen the rational use of CNC machine tools, but also to adopt scientific and reasonable maintenance methods to provide guarantee for the normal use of CNC machine tools.

Good maintenance is the guarantee for smooth production of enterprises. CNC machine tools are expensive. Maintenance during use will help reduce the loss of CNC machine parts, increase the service life of CNC machine tools, and ensure the normal use of machine tools. At the same time, good maintenance can effectively reduce mechanical failures of CNC machine tools, reduce the probability of production safety accidents, and ensure the safe production of enterprises. Proper routine maintenance of CNC machine tools will directly affect the accuracy of the machining center and even the service life of the machine tool.

Data Replication

When the machine tool factory is handed over to i-Japan, it should copy the final set machine data, part processing subroutines, and PLC programs to the user, in order to restore the machine tool when the battery loses power or the flash memory is confused.

At the maintenance site, we often encounter the phenomenon of lack of the above-mentioned technical data, so we cannot carry out the work. The machine tool cannot be recovered for a long time, causing great losses to users.

Sometimes the data that the machine tool factory gives to the user is printed after the first adjustment, but the data is modified in the second adjustment, but the modification record is not handed over to the user. Therefore, it is best for the user to make a copy of the data when the machine tool is working normally.

Replace The Battery

The CNC system generally has only one battery box, which is fixed on the bottom right wall of the main box, and the battery box cover is located on the right side of the 40A power board. Early use is a C-type kangpo battery, 3.6V.The later use is three AA type high-energy batteries, 4.5V, normal In all cases they can be used for 5 years. When the voltage drops to 2.7V, the system will issue an alarm No. 1. If the voltage is lower than 2.7V, the data will be lost. The BAU alarm is visible from the interrupt stack. So don’t cut off the power again when you find the alarm of No. I. Wait until the battery is replaced before shutting down.

Due To The Unstable Voltage Of The Domestic Power Grid

sometimes the machine tool factory requires the user to install a voltage stabilizer. If only to stabilize the numerical control power supply voltage, a purified power supply can be used. It can stabilize voltage and suppress higher harmonics. Large voltage regulators must be used for the entire machine. At present, there are two main types of domestic production, self-disaster type and magnetic adjustment type. When the voltage fluctuates frequently, the magnetic adjustment type should be used, because this equipment adjusts smoothly and has no high-order harmonic output.

The Designed Working Environment Temperature

The designed working environment temperature of Siemens CNC system is lower than 45°C If the ambient temperature is too high or the heat dissipation conditions are not good, it will cause an alarm, and an air conditioner should be installed. But the most harmful to the CNC system is humidity. Conventional wisdom holds that wet environments tend to short circuit boards. But in practice, it is also common to see open circuits caused by oxidation of solder joints caused by electrolysis or other reasons.

The Detail Of BE-CU cnc machining Shop

BE-CU.COM – As an accomplished CNC machining Service Manufacturer and CNC shop, BE-CU Prototype has been specialized in OEM CNC lathing, custom CNC machining parts production and rapid CNC machining services China for over 35 years and always maintaining the highest standard in delivery speed and reliable quality of precision CNC manufacturing components. With the help of high-level technology and efficient equipment, as well as rigorous attitude, BE-CU passed the ISO9001:2015 quality certification, which supports the long-term development of CNC milling services, CNC turning services, CNC milling-turning, CNC drilling services, 3/4/5 axis machining, gear machining services, CNC machining China custom parts and service, small parts machining, etc.Our CNC machining products can be utilized in a broad range of industries. Contact us for email: [email protected]