Selecting the right tools for CNC lathes is critical to achieving efficient and high-quality machining results. The choice of tools depends on various factors, including the material being machined, the type of operation, cutting conditions, and desired surface finish. Here are some key considerations and common types of tools used in CNC lathe operations:

Considerations for Tool Selection

- Material of the Workpiece: Different materials require specific cutting tools. For example, carbide inserts are commonly used for machining steel and aluminum, while ceramic or CBN inserts are suitable for high-speed machining of hardened materials.

- Cutting Operation: The type of cutting operation, such as roughing, finishing, threading, grooving, or parting-off, determines the appropriate tool geometry and cutting edge.

- Cutting Speed and Feed Rate: The cutting speed and feed rate influence tool performance and tool life. Select tools capable of handling the recommended cutting parameters for the specific material and operation.

- Machine Stability and Rigidity: The rigidity of the CNC lathe affects the tool’s ability to withstand cutting forces. Choose robust tools that can handle the machine’s stability and avoid chatter or vibration during cutting.

- Surface Finish Requirements: For achieving a desired surface finish, select tools with appropriate geometries and cutting edge preparations.

- Tool Life and Cost: Consider the expected tool life and tool cost when choosing cutting tools. Balancing tool life and cost is essential to optimize machining efficiency.

Common Types of Cutting Tools for CNC Lathes:

- Turning Inserts: These are the most common type of tools used in CNC lathe operations. They come in various shapes and geometries, such as square, triangular, and round, for roughing and finishing operations.

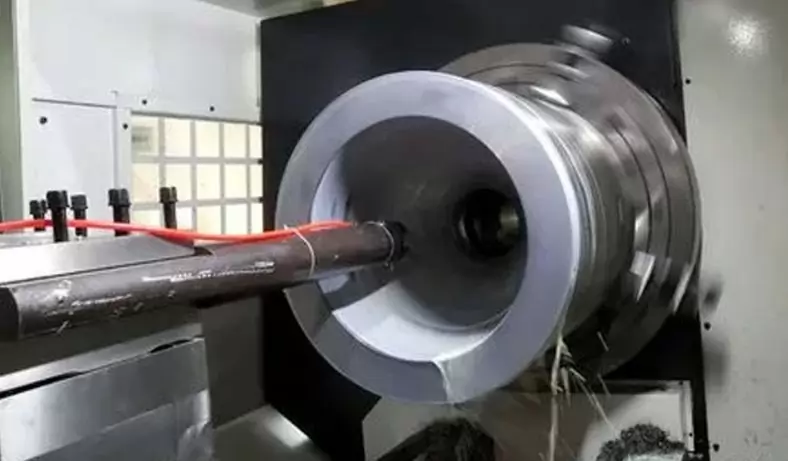

- Boring Bars: Boring bars are used for enlarging existing holes or creating internal features in workpieces.

- Parting and Grooving Tools: Parting-off tools are used for cutting off a workpiece from the main bar stock, while grooving tools create grooves on the workpiece surface.

- Threading Tools: Threading inserts and toolholders are used for cutting external or internal threads on the workpiece.

- Drill Inserts: CNC lathes equipped with live tooling can use drill inserts for drilling holes on the workpiece.

- Milling Cutters (Live Tooling): In CNC lathes with live tooling capability, milling cutters can perform milling operations, such as contouring and pocketing, in addition to turning.

- Specialty Inserts: Depending on the application, specialty inserts like ceramic inserts for high-speed machining or diamond inserts for hard materials may be used.

Always follow the manufacturer’s recommendations for cutting tool selection, cutting parameters, and tool maintenance to maximize tool life and achieve optimal machining results. Additionally, proper tool setup and CNC lathe programming play crucial roles in ensuring successful machining operations.

The most commonly used tool for contour milling is the end mill. The following mainly describes the selection of the size of the milling cutter and the number of teeth.

The Dimensions Of End Mills

In contour milling, the factors that need to be considered for the end mill include: the diameter of the end mill, the length of the end mill, and the length of the spiral groove. The diameter of the end mill is used first. Because the tool with a large diameter has high bending strength, it is not easy to cause bending and vibration during processing, but pay attention to the tool radius of the end mill must be smaller than the minimum radius of curvature of the part contour, generally Take 0.8~0.9 times of the minimum curvature radius. In addition, the protruding length of the tool should be as short as possible. The longer the length of the end mill, the lower the bending strength and the greater the degree of bending under force, which will affect the quality of processing, and is prone to vibration and wear of the cutting edge.

Regardless of the overall tool length, the helical flute length determines the maximum depth of cut. In practical applications, the cutting attempt in the z direction generally does not exceed the radius of the tool; for end mills with a smaller diameter, 1/3 of the diameter of the tool is generally selected as the cutting depth.

Also The Number Of Teeth

Small or medium diameter milling cutters, usually with 2 or 3 co-located teeth (or more). The type of workpiece material to be machined and the nature of the machining are often the determining factors in selecting the number of teeth. In the processing of workpiece materials with high plasticity, such as aluminum and magnesium, in order to avoid the generation of built-up edge, end mills with few teeth are commonly used, such as two-tooth (C spiral groove) production milling cutters. End mills have fewer teeth to avoid built-up edge when the cut is larger because of the larger chip space between the helical flutes.

The opposite is true for harder materials, as he needs to consider two other factors – tool chatter and tool offset. When machining brittle materials, choosing a multi-tooth end mill will reduce tool chatter and deflection, as more teeth provide a smoother cut. For small or medium diameter end mills, three-tooth end mills have the advantages of two-tooth and four-tooth tools, and have good processing performance. Keyway milling cutters usually have two helical grooves, which are similar to drills and are cut vertically into solid material.

At Be-cu.com,we use advanced equipment to offer you Unparalleled precision for producing metal and plastic machining parts

- We combine the latest CNC milling and turning processes with proprietary technology to deliver high quality, on-demand parts.

- Our team of engineers and machinists program the equipment to optimize cutting time, surface finish, and final tolerance to meet your design specifications

- We specialize in cnc precision machining, single part prototyping, short to medium production runs, manufacture parts on time, every time, so you can stay ahead of schedule

- CNC machining can create very similar parts to series parts. It is often more efficient and faster than other rapid prototyping technologies for the manufacture of a quantity of prototypes between 1 and 10 parts . We also recommend CNC machining for parts with large sizes (greater than 600 mm).

Contact Us ([email protected]) Now for your Custom CNC Machining, We are your best online cnc machining and rapid prototyping services choice!