The principle of laser cutting is basically the same as that of the convex lens converging sunlight to ignite a match. The laser emitted by the laser undergoes a series of treatments, and after being focused by the lens, the energy is highly concentrated in a small range. If the processed material absorbs the laser well, the material in the irradiated area will be absorbed The energy of the laser heats up rapidly.

Depending on the properties of the material (such as melting point, boiling point, and temperature at which chemical changes occur), the workpiece will undergo a series of physical or chemical changes, such as melting, gasification, oxide formation, discoloration, etc. This is the principle of laser processing .

The Advantages Of Laser Processing

Advanced processing mode and high efficiency

The focused very fine laser beam is like a tool, which can remove the material on the surface of the object point by point. Its advanced nature is that the marking process is non-contact machining without mechanical extrusion or mechanical stress, so it will not damage the processed items; due to The laser focused size is small, the heat-affected area is small, and the processing is fine. Therefore, some processes that cannot be achieved by conventional methods can be completed.

Low cost, fully automatic, easy to operate

The “tool” used in laser processing is a focused light spot, and no additional equipment and materials are required. As long as the laser can work normally, it can be continuously processed for a long time. The laser processing speed is fast and the cost is low. The laser cutting is automatically controlled by the computer, and no human intervention is required during production.

Easy product identification

After laser marking, since the surface material is peeled off, the marking will not fade due to harsh environments, and its information can be maintained permanently. Laser can mark unique serial numbers for products, which is convenient for product identification and traceability. It is difficult to imitate the special effect of laser marking by traditional technology, so laser marking has outstanding performance in anti-counterfeiting.

Meet environmental requirements

Laser processing is non-toxic and harmless, and the processed products exceed the production and environmental protection requirements of various countries. It is a safe and clean precision machining method. Customers do not need to worry about export restrictions due to silk screen printing and corrosion processes.

Achieve zero backlog

Laser processing is flexible and easy to change. Marking products according to the orders of different customers can effectively avoid the differentiated production of the same product and reduce the risk of product backlog.

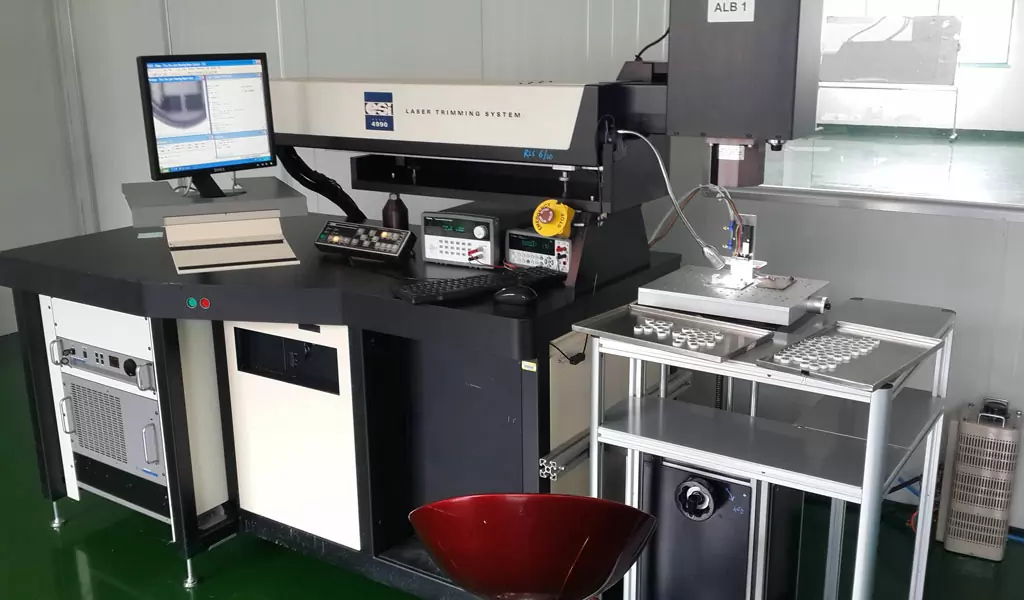

The Detail Of BE-CU Laser Cutting Company

BE-CU.COM Laser Cutting provides services to a wide network of industries and markets. BE-CU is uniquely positioned to Laser Cut, Laser Engrave, Precision CNC Machine and Precision Finish Grind parts and components.We use large format industrial laser cutting machines that are extremely precise with up to .001” tolerance. Not only we cut and engrave your project, we are ready to answer any questions you may have about the process and give you expert advice.

So, reach out even if you’re unsure of your specific need or if you think you may require a different type of manufacturing service(as laser cutting medical parts). Laser cutting service by BE-CU makes ordering your parts simple. Just upload your CAD files onto the platform for an instant price and lead time. Our mission is to save engineers’ time for value-adding activities.

-

Etching LED EMC Packaging Bracket

-

Etching Low Resistivity Copper 110 Contact Rings

-

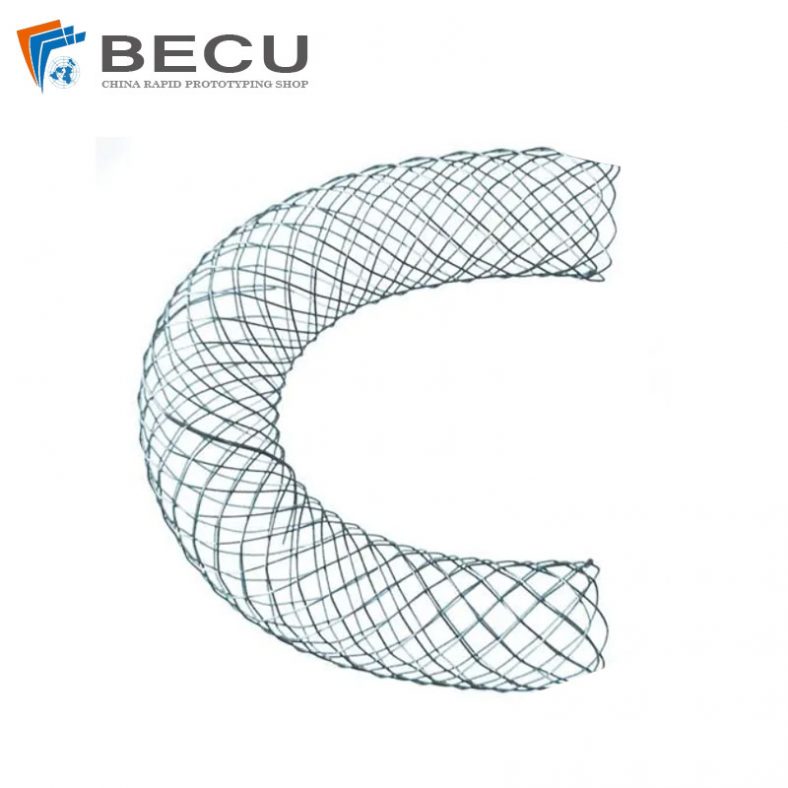

Laser Cut Nitinol Stent For Bile Duct

-

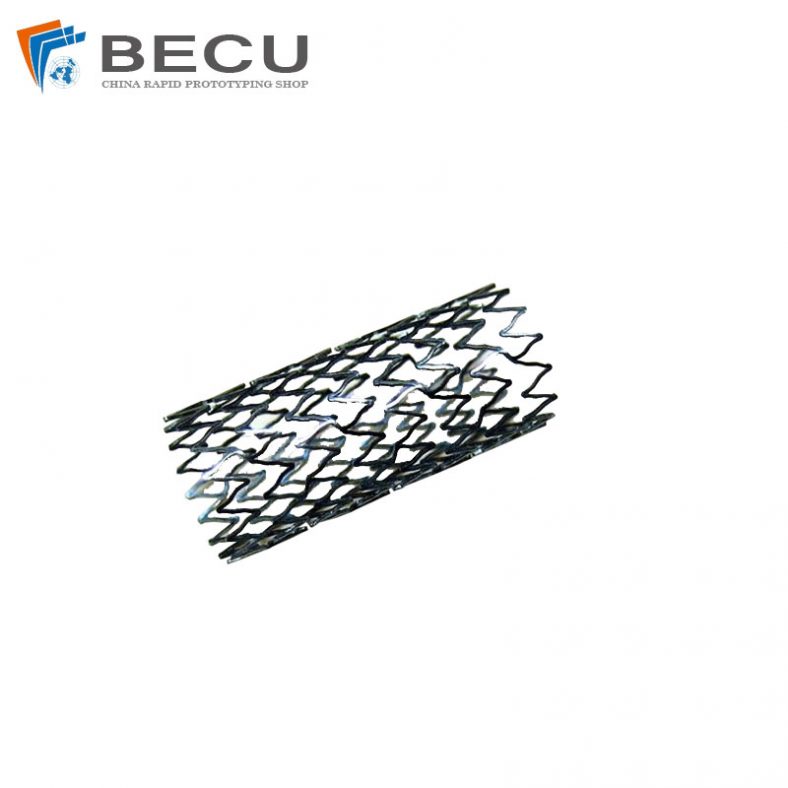

Stents For Carrying Valves And Venous Valve Replacement Devices

-

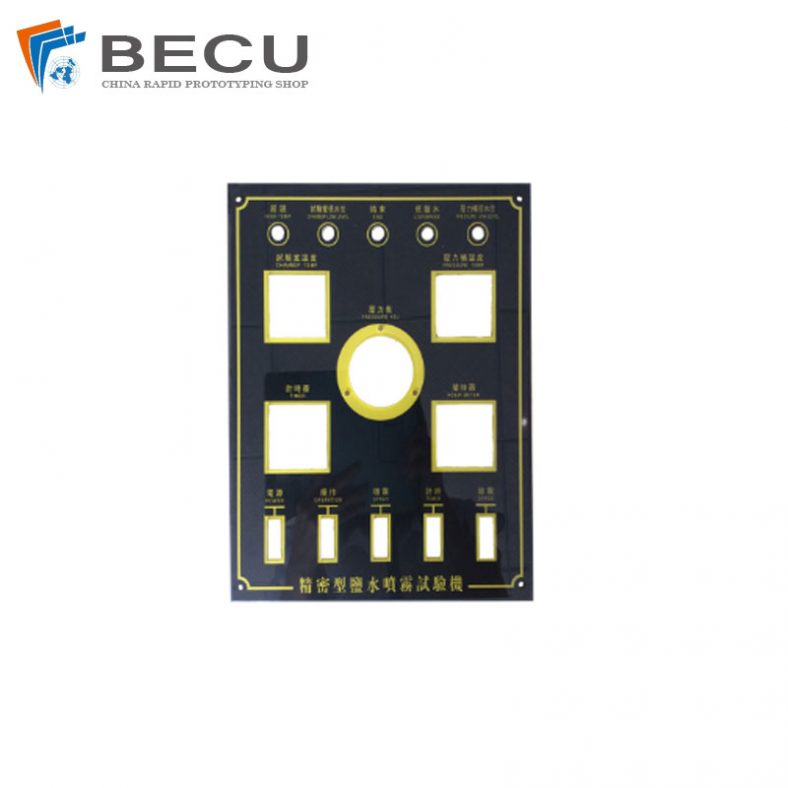

Laser Cutting PC Anti-Static Membrane Switch

-

Precision Engraving Special-Shaped Natural Color PEEK Parts

-

Acrylic Laser Cut Signs

-

Acrylic Laser Cut Earrings