The evolution of aviation technology has been marked by numerous innovations, among which Computer Numerical Control (CNC) machining stands out as a pivotal advancement. CNC machining has revolutionized the production of intricate, precise, and high-performance components essential for modern aircraft. This article delves into the top 20 CNC machined components for airplanes, highlighting their significance, manufacturing processes, and impact on the aviation industry.

1. Turbine Blades

Turbine blades are crucial components in turbines, and their shape and principle directly affect the performance and efficiency of turbines. In turbines, turbine blades play an important role in carrying, converting and transmitting kinetic energy.

Therefore, designing a reasonable shape and principle of turbine blades is crucial to improving the efficiency and performance of turbines.

- Importance : Turbine blades are critical components in jet engines, responsible for converting high-temperature, high-pressure gas into mechanical energy. These blades must withstand extreme thermal and mechanical stresses.

- Manufacturing Process : CNC machining, particularly 5-axis machining, is employed to create the complex geometries of turbine blades. The process involves using high-strength materials like titanium and nickel-based superalloys, ensuring precise tolerances and surface finishes.

- Impact : The precision of CNC machined turbine blades enhances fuel efficiency, reduces emissions, and increases the overall reliability of jet engines.

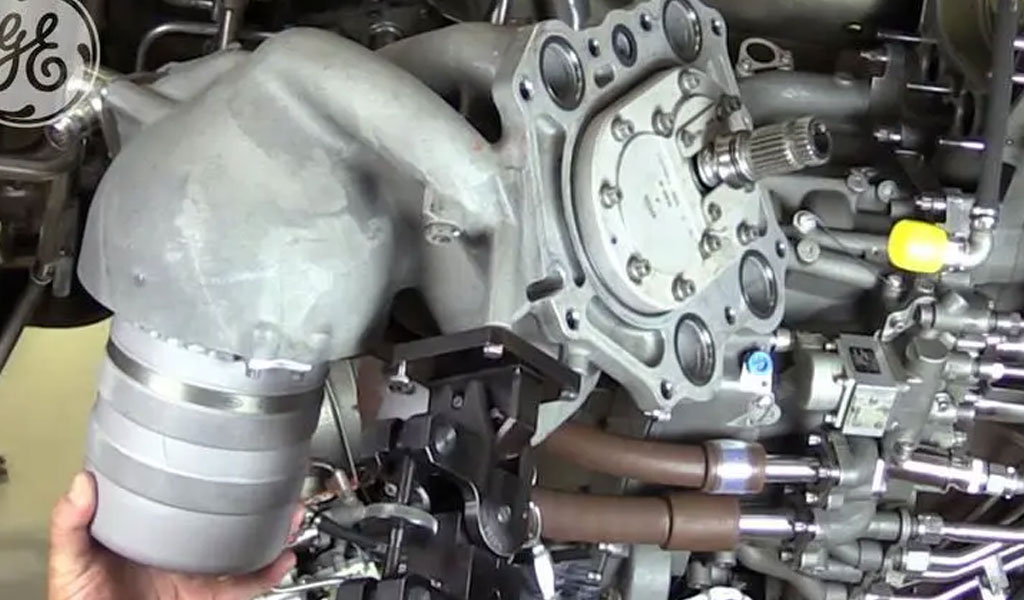

2. Engine Mounts

The engine bracket is the connecting part between the engine and the vehicle body, supporting the entire engine. Its strength and dynamic performance directly affect the safety and comfort of the vehicle.

The shape of the lower bracket of the automobile engine is complex, and various precision requirements are high. In the actual processing process, many process problems such as workpiece deformation, interference, and inaccurate fit will be encountered.

- Importance : Engine mounts secure the engine to the aircraft’s airframe, absorbing and dampening vibrations and loads during operation.

- Manufacturing Process : CNC machining is used to produce engine mounts from materials such as aluminum, titanium, and steel. The process ensures high precision and strength, which are crucial for safety and performance.

- Impact : CNC machined engine mounts contribute to the structural integrity and stability of the aircraft, ensuring smooth and safe operation.

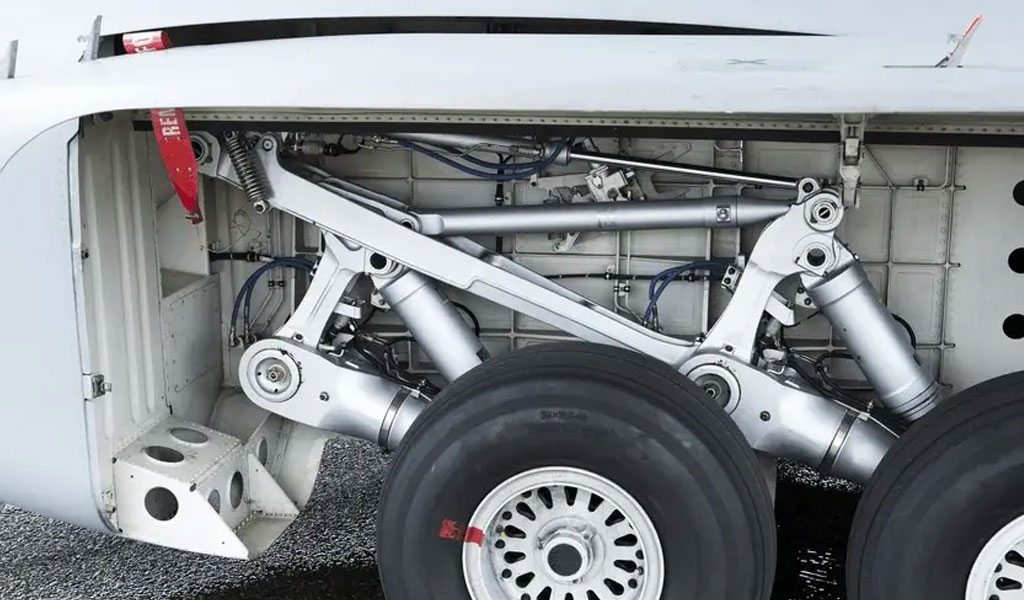

3. Landing Gear Components

The landing gear is an attachment device at the bottom of the aircraft used to support the aircraft during takeoff and landing or taxiing on the ground (water surface) and to move on the ground (water surface).The main landing gear is the main load-bearing part of the landing gear, generally installed under the main wing of the aircraft fuselage.

It usually consists of two main parts: the main landing gear strut and the main landing gear tire assembly.

- Importance : Landing gear components bear the brunt of takeoffs and landings, requiring exceptional strength and durability.

- Manufacturing Process : CNC machining produces landing gear components like struts, axles, and shock absorbers from high-strength materials such as titanium and high-grade steel. The process ensures precise dimensions and surface finishes.

- Impact : The reliability and robustness of CNC machined landing gear components are critical for the safe landing and takeoff of aircraft, directly impacting passenger safety and aircraft longevity.

4. Wing Spars

In the beam wing structure, the spar is the most important longitudinal member, bearing all or most of the bending moments and shear forces on the wing. The spar is generally composed of flanges, webs and struts, and different structures are developed according to the specific force conditions. The flange is usually made of forged aluminum alloy or high-strength alloy steel, and the web is made of hard aluminum alloy plate, which is connected to the upper and lower flanges with screws or rivets. The flange and the web form an I-beam, which bears the bending moments and shear forces converted from external loads.

The longitudinal mast is very similar to the spar. The difference between the two is that the flange of the longitudinal mast is very weak and is not connected to the fuselage. Its length is sometimes only a part of the wingspan. The longitudinal mast is usually arranged at the leading and trailing edges of the wing, connected to the upper and lower skins to form a closed box section to bear torque. The longitudinal mast near the trailing edge can also hang flaps and ailerons.

- Importance : Wing spars are the primary structural components of an aircraft’s wing, providing support and maintaining the aerodynamic shape.

- Manufacturing Process : CNC machining of wing spars involves milling and drilling operations on large aluminum or composite material blocks. The precision of CNC machining ensures the integrity and performance of the wing structure.

- Impact : CNC machined wing spars enhance the structural strength and aerodynamic efficiency of the aircraft, contributing to overall flight performance.

5. Avionics Housings

The electrical system of an aircraft consists of two parts: the power supply system and the electrical equipment.

The power supply system is the part that provides electrical energy to the aircraft, such as the engine-driven alternating current generator (AC), auxiliary power unit (APU) and external power supply.

- Importance : Avionics housings protect and encase sensitive electronic components essential for navigation, communication, and control systems.

- Manufacturing Process : CNC machining produces avionics housings from lightweight and durable materials such as aluminum and magnesium alloys. The process ensures precise fitting and protection for the electronic components.

- Impact : The precision of CNC machined avionics housings ensures the reliability and longevity of critical electronic systems, enhancing the safety and efficiency of aircraft operations.

6. Control Surface Components

Analog control panels consist of a variety of shaped and color-coded switches, knobs, protective covers, etc.

The control panel provides visual and tactile feedback for the pilot’s operations, significantly improving the accuracy and speed of the pilot’s operations.

Devices that operate important equipment on the aircraft are equipped with protective covers to prevent misoperation.

- Importance : Control surfaces, including ailerons, elevators, and rudders, are essential for maneuvering and stabilizing the aircraft.

- Manufacturing Process : CNC machining is used to create control surface components from lightweight and strong materials like aluminum and composites. The process ensures precise aerodynamic shapes and smooth finishes.

- Impact : CNC machined control surface components improve the responsiveness and stability of aircraft, enhancing maneuverability and safety.

7. Fuselage Frames

The frame structure is welded from high-strength steel pipes, and the armor is fixed to the fuselage by welding or screws. Features: simple and strong structure, low cost. However, the manufacturing accuracy is poor.

- Importance : Fuselage frames form the backbone of the aircraft’s main body, providing structural support and housing passengers and cargo.

- Manufacturing Process : CNC machining of fuselage frames involves cutting, drilling, and milling large sections of aluminum or composite materials. The precision of CNC machining ensures the structural integrity and weight optimization of the fuselage.

- Impact : The strength and precision of CNC machined fuselage frames contribute to the overall durability and safety of the aircraft, enabling it to withstand various operational stresses.

8. Fuel System Components

The type of fuel supply system for piston engine aircraft mainly depends on the number of engines. The fuel systems of single-engine aircraft include gravity fuel supply system, fuel pump fuel supply system and upper wing jet fuel supply system.

Multi-engine aircraft often use cross-fuel supply system, where the fuel tank on either side can supply fuel to the engine on the other side, improving the reliability of the fuel supply system.

- Importance : Fuel system components, including pumps, valves, and injectors, are vital for the efficient delivery and management of fuel.

- Manufacturing Process : CNC machining produces fuel system components from corrosion-resistant materials like stainless steel and titanium. The process ensures precise tolerances and smooth surfaces, essential for proper fuel flow and pressure management.

- Impact : The precision of CNC machined fuel system components enhances fuel efficiency and reliability, reducing operational costs and environmental impact.

9. Hydraulic System Parts

A complete hydraulic system consists of five parts, namely power components, actuators, control components, auxiliary components and hydraulic oil.

The hydraulic system mainly consists of five parts: power components (oil pumps), actuators (oil cylinders or hydraulic motors), control components (various valves), auxiliary components and working media.

- Importance : Hydraulic systems control various aircraft functions, including landing gear, brakes, and flight control surfaces.

- Manufacturing Process : CNC machining is used to produce hydraulic system parts from high-strength materials such as steel and aluminum. The process ensures precise dimensions and smooth finishes, critical for fluid dynamics and pressure management.

- Impact : The reliability and performance of CNC machined hydraulic system parts are essential for the safe and efficient operation of aircraft systems.

10. Cabin Interior Components

As the name implies, aircraft interior decoration refers to the decorative parts inside the aircraft, which is the decoration of the interior space of the aircraft. Aircraft interior can be divided into cockpit interior and cabin interior according to the areas where the pilot and passengers are located. The cabin interior is the soul and main body of the entire interior, including the ceiling, side panels, luggage compartments, partition panels, door curtains, carpets, etc.

What kind of lighting, seat style, and even the materials and installation methods used for the aircraft cabin covering all affect the interior effect and belong to the category of aircraft interior.

- Importance : Cabin interior components, including seats, overhead bins, and panels, contribute to passenger comfort and safety.

- Manufacturing Process : CNC machining produces cabin interior components from lightweight materials like aluminum and composites. The process ensures precise fitting and aesthetic finishes.

- Impact : The precision of CNC machined cabin interior components enhances passenger comfort and safety, contributing to the overall travel experience.

11. Heat Shields

In the aerospace field, turbine engines are the core of aircraft power. Turbine heat shields not only provide thermal insulation protection but also improve the engine’s combustion efficiency and thrust output.

- Importance : Heat shields protect critical components from the extreme temperatures generated during flight and engine operation.

- Manufacturing Process : CNC machining is used to produce heat shields from heat-resistant materials such as titanium and ceramics. The process ensures precise shapes and optimal thermal protection.

- Impact : The reliability of CNC machined heat shields is crucial for protecting sensitive components, enhancing the safety and longevity of the aircraft.

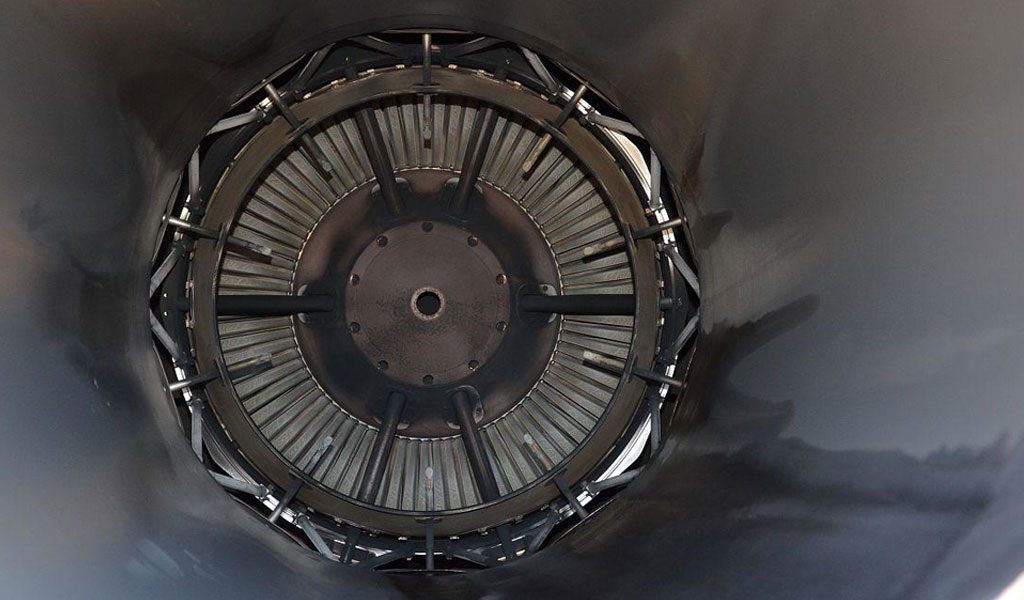

12. Exhaust Components

The tail nozzle is one of the components of the turbojet engine of a jet aircraft. Its main function is to eject the products of jet aircraft fuel combustion, such as carbon dioxide, sulfur dioxide, carbon monoxide, nitrogen oxides, and incompletely burned small molecular hydrocarbons, to discharge exhaust gas. It also uses the reaction force generated by the air during injection to propel the aircraft. However, in a turboprop engine, the thrust provided by the tail nozzle is only a part of the aircraft’s power.

The main power of the aircraft is provided by the driving propeller of the turboprop engine.

- Importance : Exhaust components manage and expel the byproducts of combustion, contributing to engine efficiency and emissions control.

- Manufacturing Process : CNC machining produces exhaust components from high-temperature alloys like Inconel and stainless steel cnc machining. The process ensures precise tolerances and smooth surfaces for optimal flow and durability.

- Impact : CNC machined exhaust components improve engine efficiency and reduce emissions, contributing to environmental sustainability and regulatory compliance.

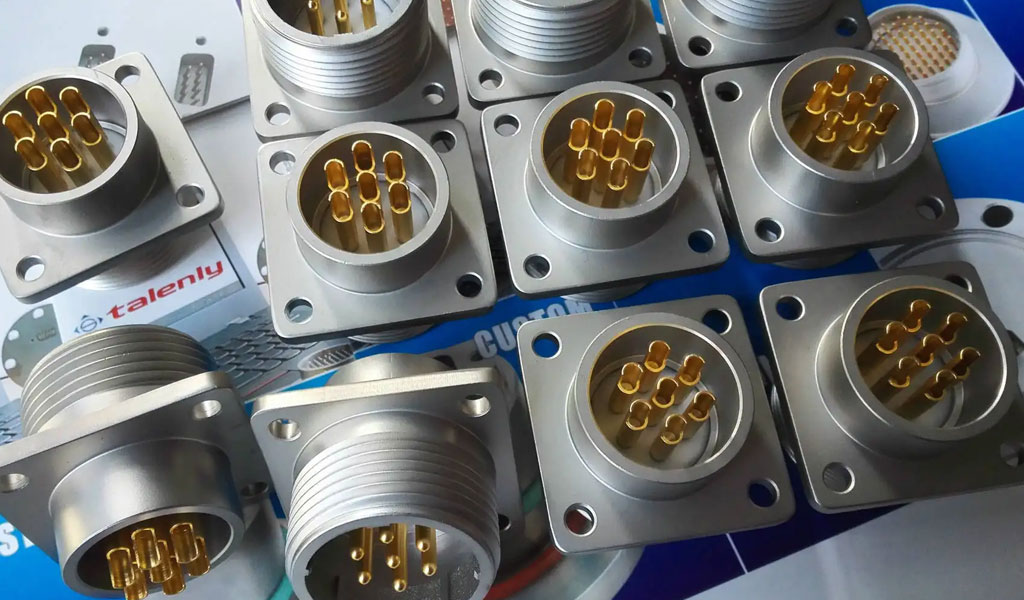

13. Electrical Connectors

In addition to meeting general performance requirements, electrical connectors must have good contact, reliable operation, and easy maintenance. Their reliability directly affects the normal operation of the aircraft circuit and involves the safety of the entire host.In addition to meeting general performance requirements, electrical connectors must have good contact, reliable operation, and easy maintenance. Their reliability directly affects the normal operation of the aircraft circuit and involves the safety of the entire host.

- Importance : Electrical connectors ensure reliable electrical connections for various systems, including avionics, lighting, and power distribution.

- Manufacturing Process : CNC machining produces electrical connectors from materials like aluminum and brass. The process ensures precise dimensions and reliable connections.

- Impact : The reliability of CNC machined electrical connectors is essential for the uninterrupted operation of electrical systems, enhancing aircraft safety and performance.

14. Sensor Housings

The wheel speed sensor of civil aircraft is a key device in the aircraft braking system. It is used for anti-skid control of the braking system to prevent the wheels from deep skidding and locking during braking.

- Importance : Sensor housings protect sensitive instruments that monitor and control various aircraft functions, including navigation, weather, and engine performance.

- Manufacturing Process : CNC machining is used to create sensor housings from durable materials such as aluminum and stainless steel. The process ensures precise fitting and protection for the sensors.

- Impact : The precision of CNC machined sensor housings ensures the accuracy and reliability of critical sensors, enhancing overall flight safety and efficiency.

15. Fasteners

Aircraft fasteners refer to small parts such as various bolts, nuts, washers, pins and clips used to connect important parts on the aircraft. According to the location and purpose of use, they can be divided into three categories: structural fasteners, engine fasteners and electrical connection fasteners.Structural fasteners include high-strength bolts, nuts and washers that connect the main structures such as wings, fuselage and tail. These fasteners bear the important responsibility of maintaining stable flight of the aircraft.

If the joint surface is loose or the fasteners are missed, it may cause the aircraft to lose control or a serious accident.

Engine fasteners are parts that connect the engine to the wing or fuselage. Because they bear the weight of the engine and the huge pressure during operation, they require high temperature resistance, fatigue resistance, high strength and other characteristics. In flights, the reliability of the engine and the stability of the operating state are crucial to flight safety.

Electrical connection fasteners are mainly used to connect various cables, wires and electrical equipment on the aircraft. Their material selection and production quality are also directly related to the reliability of the aircraft’s electrical equipment. Therefore, the performance and quality of aircraft electrical connection fasteners are strictly regulated by international standards and aviation standards.

- Importance : Fasteners, including bolts, screws, and rivets, are essential for assembling and securing various aircraft components.

- Manufacturing Process : CNC machining produces fasteners from high-strength materials like titanium and stainless steel. The process ensures precise dimensions and consistent quality.

- Impact : The reliability of CNC machined fasteners is crucial for the structural integrity and safety of the aircraft, preventing component failure and ensuring secure assembly.

16. Bearing Housings

Aircraft engine bearings are important components that support the rotation of aircraft engines. Their main functions are to provide rotational power and bear the axial and radial loads of the engine.

The structure of aircraft engine bearings usually consists of an inner ring, an outer ring, a cage, a seal, and a dust cover.

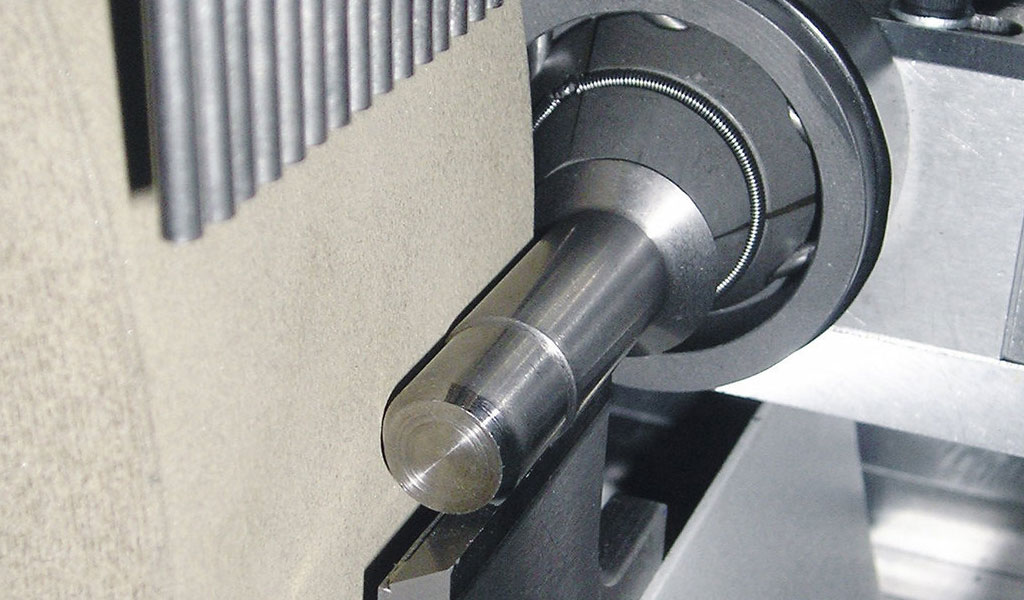

- Importance : Bearing housings support and enclose bearings used in various aircraft systems, including engines, landing gear, and control surfaces.

- Manufacturing Process : CNC machining is used to produce bearing housings from materials like aluminum and steel. The process ensures precise dimensions and optimal performance.

- Impact : The precision of CNC machined bearing housings enhances the performance and longevity of bearings, reducing maintenance costs and improving aircraft reliability.

17. Propeller Hubs

The hub is a component fixed to the center of a ship or aircraft propeller, which is mainly responsible for connecting, supporting and protecting the propeller blades.

The hub is usually made of metal materials, and its shape and structure are carefully designed to rotate quickly and withstand the inertia and centrifugal forces caused by high-speed rotation.

The shape and structure of the hub vary depending on the propeller design. Generally speaking, the shape of the hub can be divided into two main types: ship and aircraft. The ship hub is generally spherical or oblate, while the aircraft hub is usually a slender cone, which allows the propeller to reduce air resistance and improve flight efficiency during high-speed flight.

- Importance : Propeller hubs secure the propeller blades to the aircraft’s engine, transmitting power and ensuring balanced rotation.

- Manufacturing Process : CNC machining produces propeller hubs from high-strength materials like aluminum and titanium. The process ensures precise fitting and balance.

- Impact : The precision of CNC machined propeller hubs ensures efficient power transmission and smooth operation, enhancing overall aircraft performance.

18. Airframe Brackets

The landing gear of an aircraft is one of the most important parts of the aircraft structure. It is an important component that supports the aircraft during takeoff, landing and taxiing.

It plays a vital role in the takeoff and landing of the aircraft. Its structure and design vary depending on the type of aircraft, but there are some common features.

The main components of an aircraft landing gear include shock struts, main and nose landing gears, as well as wheels and brakes. Shock struts are hydraulic or pneumatic systems that help absorb the impact of landing and taking off and driving on rough terrain. The main and nose landing gears are supporting structures that connect the shock struts to the aircraft frame. Wheels and brakes are installed on the landing gear to allow the aircraft to roll on the ground and stop.

- Importance : Airframe brackets provide structural support and attachment points for various aircraft components, including wings, engines, and landing gear.

- Manufacturing Process : CNC machining is used to create airframe brackets from materials like aluminum and titanium. The process ensures precise dimensions and strength.

- Impact : The reliability of CNC machined airframe brackets is crucial for the structural integrity and safety of the aircraft, ensuring proper attachment and support for critical components.

19. Thrust Reverser Components

The thrust steering device can control the thrust direction generated by the aircraft engine. In essence, it is a thrust steering nozzle. For example, the thrust vectoring engine mainly relies on the thrust steering nozzle to achieve thrust direction control, which actually utilizes thrust vector control technology.

- Importance : Thrust reverser components help decelerate the aircraft during landing by redirecting engine thrust.

- Manufacturing Process : CNC machining produces thrust reverser components from high-strength materials like titanium and Inconel machining. The process ensures precise dimensions and smooth operation.

- Impact : The efficiency of CNC machined thrust reverser components enhances landing safety and reduces wear on brakes, contributing to overall aircraft performance.

20. Antenna Mounts

A device that supports the antenna structure and enables the antenna to move within a specified airspace. It uses the antenna control system to make the antenna move according to a predetermined rule or follow the target movement; and through the axis position detection device, it accurately measures the direction of the target.

- Importance : Antenna mounts secure communication and navigation antennas to the aircraft, ensuring optimal signal reception and transmission.

- Manufacturing Process : CNC machining is used to create antenna mounts from materials like aluminum and stainless steel. The process ensures precise fitting and durability.

- Impact : The precision of CNC machined antenna mounts ensures reliable communication and navigation, enhancing overall flight safety and efficiency.

China Top Airplanes Parts CNC Machining Company

CNC machining plays a vital role in the aviation industry, enabling the production of high-precision, high-performance components essential for modern aircraft. The top 20 CNC machined components discussed in this article demonstrate the diverse applications and significant impact of CNC machining on aircraft safety, efficiency, and performance. As technology continues to advance, CNC machining will remain a cornerstone of aviation manufacturing, driving innovation and excellence in the industry.

BE-CU has established a well-deserved reputation for quality, dependability, cost-effective and timely delivery in the CNC machining industry. To meet your expectations for aerospace machining projects, our team of machinists, and engineers will work closely and efficiently through all stages of product development, from prototype to production.We incorporate the latest in metal shaping, grinding, laser cutting and deburring techniques to create precision parts too complex for lesser machine shops. Some examples of our OEM aircraft parts and machining techniques include:

-

Precision CNC Machining Unmanned Aerial Vehicle Motor Base

-

3-Way Centrifugal Compressor Closed Impeller By 5 Axis Machining

-

3D Printing 316l Stainless Steel Fan Blade

-

3D Printing Stainless Steel Airplane Engine Model

-

3D Printed Stainless Steel Jet Turbine Blade

-

5 Axis Precision Machining Aluminum 7075 Aerospace Parts

-

Precision 5 Axis Machining Aluminum 6061 Aerospace Parts

-

5-Axis Linkage Cnc Machining Aluminum Turbocharger Impeller

We recognize that every project and its application is different, so we provide unique but practical solutions for every client, including precision machining services and custom surface finishing. So why wait? Contact us today, and let’s get started on creating your high-quality aerospace machined part.