In actual production, the tools used to help users quickly and accurately check the dimensions of various parts and determine whether they meet the design dimensions are called inspection tools.

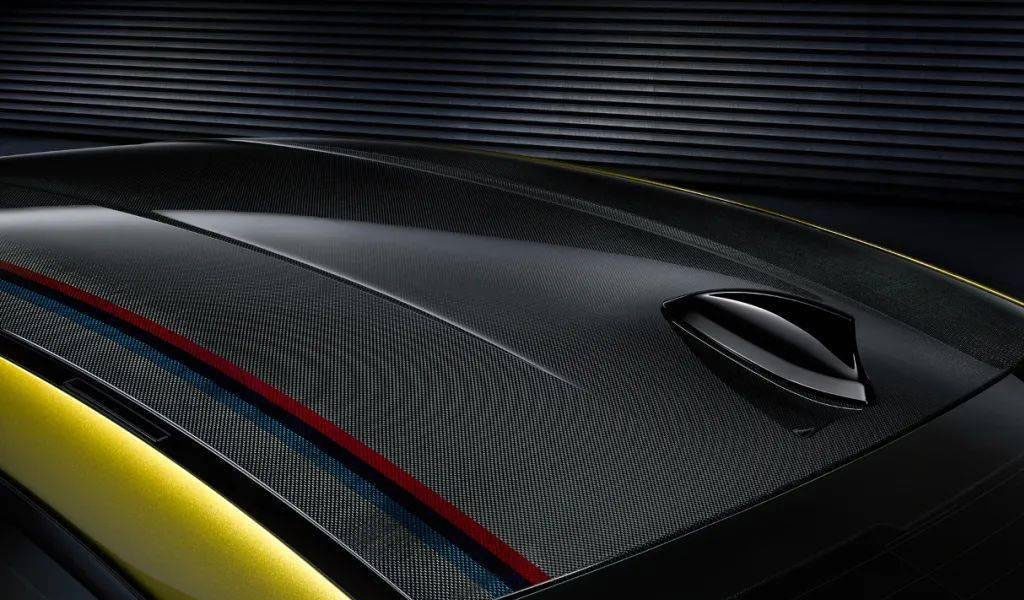

Traditional inspection tools are mostly made of aluminum alloy and steel. The emergence of carbon fiber inspection tools has been used more and more. In this article, let’s take a look at the advantages of carbon fiber inspection tools.

In the application process of the inspection tool, the lightweight inspection tool can make the operation more convenient, and the selection of lightweight structural materials is more important.

The density of carbon fiber composite materials is only 1.7g/cm3, while the density of aluminum is 2.7g /cm3, the density of steel is 7.85g/cm3, in comparison, the weight reduction effect of carbon fiber inspection tools is more significant.The role and application areas of carbon fiber inspection

The Role Of Carbon Fiber Inspection

Carbon fiber is a high-strength, low-density material with excellent mechanical properties. It has been widely used in aircraft, automobiles, ships, construction and other fields. In order to ensure the performance and strength of carbon fiber materials during use, they need to be quality tested. Carbon fiber inspection is a non-destructive testing technology that can detect carbon fiber materials without damaging the materials to clarify the performance and strength of the materials.

Application Areas Of Carbon Fiber Inspection

Carbon fiber inspection can be widely used in various fields, such as aircraft, automobiles, ships, construction, etc. Specifically include the following applications:

- Aircraft field: Carbon fiber composite materials have become one of the main materials for aircraft manufacturing, and carbon fiber inspection can ensure the quality and reliability of aircraft parts.

- Automobile field: As the requirements for lightweight automobiles become higher and higher, the application of carbon fiber materials is constantly expanding, and carbon fiber inspection can ensure the performance and strength of automobile parts.

- Ship field: The construction of new marine parts pays more and more attention to lightweight and strength, and the application of carbon fiber materials is becoming more and more extensive. Carbon fiber inspection and testing can ensure the quality and reliability of ship materials.

- Construction field: Carbon fiber reinforced composite materials are increasingly used in the construction field, such as carbon fiber reinforcement, carbon fiber concrete, etc., and carbon fiber inspection can ensure the performance and reliability of building materials.

To sum up, carbon fiber inspection is an important non-destructive testing technology that can be used to detect the quality of carbon fiber materials and clarify the performance and strength of the materials. It is widely used in various fields, such as aircraft, automobiles, ships, construction, etc. .

The inspection tool needs to accurately detect the size of various parts, so there should be no deviation in its accuracy, which requires the production material to have a certain dimensional stability. The mechanical properties of carbon fiber composite materials are very outstanding, which can meet the strength of use without bending , not deformed. At the same time, the carbon fiber composite material has a small thermal expansion coefficient, which basically does not deform with the change of working temperature, ensuring dimensional accuracy.

In the actual use process, the strength of the inspection tool should be considered. Generally, the carbon fiber inspection tool is obtained by gluing multiple carbon fiber tubes, which is suitable for some inspection tools with low operating strength, and for some inspection tools with high strength. In terms of tools, the adhesive may not meet the needs of the use strength, and it needs to be mechanically connected to ensure the use strength.

China Be-cu Prototype Material Technology Co., Ltd. is a powerful manufacturer of carbon fiber products, which have been used in the fields of medical equipment, automobile industry, etc. The raw materials are made of well-known brand materials such as Taiwan and Japan. Quality assurance, related products Long-term exports to Europe and the United States and other countries.

ISO 9001 certified. BE-CU Prototype Offering CNC machining carbon fiber and other manufacturing services for carbon fiber marterial. Various capabilities include notching, labeling, drilling carbon fiber, grinding, laser cutting carbon fiber, finishing, plating, marking, CNC milling carbon fiber and turning carbon fiber.We stock high quality 3k carbon fiber sheet in a variety of thickness, types and finish. Its a great material used in applications where light weight and strength are needed such as drones. Unlike other workshops, we have no min order and are often filling orders with a single part. We also don’t make you pay for the full sheet and you only get charged for what is used. With a large selection of material, you should find everything you need to make your project come to life. We are also able to handle larger production runs and provide a competitive pricing. If we don’t have the material or finish you require, we are more the willing to look at bringing it in for you.

What Is Carbon Fiber?Carbon fiber is made of polyacrylonitrile (PAN) (or pitch, viscose) and other organic fibers by carbonization (removal of most elements except carbon) by pyrolysis method under inert gas at high temperature above 1,000 °C. Inorganic polymer fibers with a carbon content of more than 90%.

-

3D Printing Continuous Fibres

-

3D Printing Short Fibre Filled Wires

-

Laser Cutting Carbon Fiber Positioning Keyboard

-

Cnc Turning Industrial Copper-Aluminum Clad Carbon Fiber Machinery Parts

-

Carbon Fiber Luggage Tag Ornaments

-

Laser Cutting Carbon Fiber Guitar Shape Crafts

-

Laser Cutting Carbon Fiber Drone Rack

-

Cnc Milling Carbon Fiber Finger Buckle