During the Cold War between the United States and the Soviet Union in 1950, in order to solve the problem of heat resistance of weapons, the US military conducted research on a number of materials, and finally found that at a high temperature of 2000 ° C, man-made fibers that remove impurities other than carbon have very good performance, opening the door to new stage of development.

After the 1970s, carbon fiber began to be industrialized. In the 21st century, all kinds of carbon fiber products came out in droves and were highly sought after by people. Carbon fiber board is a basic carbon fiber product, which is used in many fields. Today, I will tell you about its role in detail.

Carbon fiber panels are most commonly used in the field of building reinforcement. It is corrosion-resistant, light-weight, high-strength, wear-resistant and high-temperature resistant. Buildings exposed to the air not only have to endure the sun’s insolation, but are also often washed away by the rain. To know. Rainwater is not pure H2O, it contains some chemical substances, the pH value is less than 5.6, it is acidic, and it is corrosive to a certain extent.

The chemical properties of carbon fiber are stable and are not corroded by organic solutions, acid-base salts, alcohols and ketones. The power of nature is great. Wind energy and crustal movement will accelerate the decline of buildings. High-strength carbon fiber panels can withstand the impact of external forces to the greatest extent. It is also very convenient to construct. It does not require large instruments or a lot of manpower. The entire project can be completed in just a few days.

The Functions Of Carbon Fiber Panels

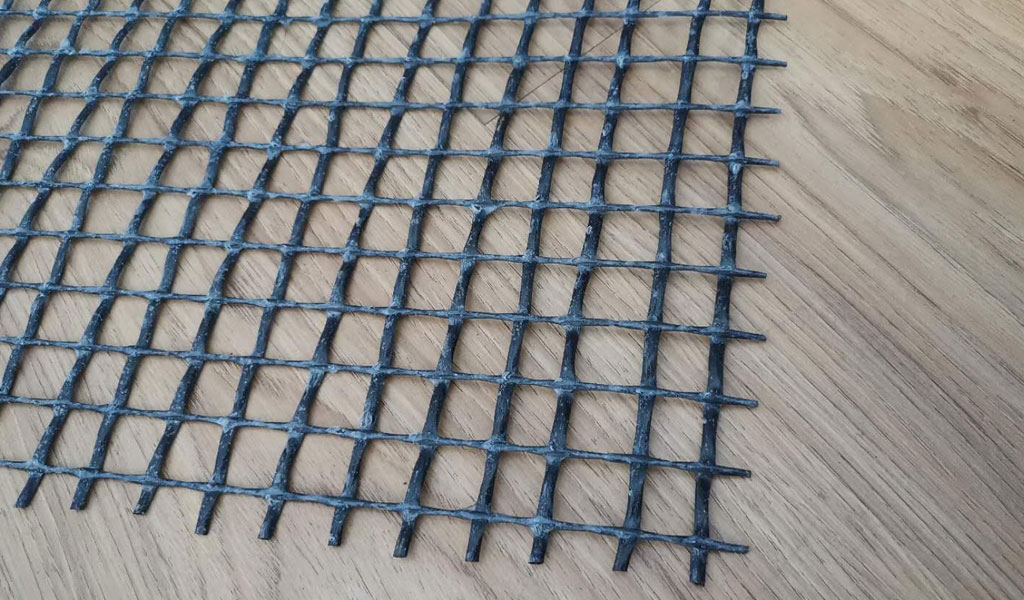

Carbon fiber panels can effectively solve the problems of difficult construction of multi-layer carbon fiber sheets and large workloads. They are mainly used for bending and shear reinforcement of concrete beams, reinforcement of concrete floors and bridge decks, reinforcement of concrete and brick masonry walls, and reinforcement of scissor walls.

Reinforcement of bridge piers, piles and other columns, and reinforcement of chimneys, tunnels, pools, concrete pipes, etc. Carbon fiber panels are carbon fibers arranged in the same direction that are impregnated and hardened with resin to form a carbon fiber plate. It has good reinforcing effect and is easy to construct.

How To Construct Carbon Fiber Panels?

- Polish the bonding parts according to the design requirements until the concrete surface is exposed, repair cracks, sections and steps, and then cut the carbon fiber plate according to the design size. Mix the matching carbon fiber board adhesive in proportion and stir evenly.

- Wipe the surface of the carbon fiber board to be pasted clean (if two layers need to be pasted, wipe both sides of the bottom carbon fiber board), and immediately apply carbon board glue until the glue layer protrudes and the average thickness is greater than 2mm.

Precautions For Carbon Fiber Panels

- The carbon fiber plate coated with carbon plate glue is gently pressed on the polished concrete surface and compacted smoothly in the direction of the optical fiber of the rubber roller. The carbon plate glue is extruded from both sides to ensure compactness and no holes. When pasting multiple carbon fiber plates in parallel, the gap between the two plates should be no less than 5mm.

- When two layers of carbon fiber boards need to be pasted, they should be pasted continuously. If it cannot be pasted immediately, the underlying carbon fiber board should be cleaned again before pasting.

- For surface protection, if the fireproof layer is to be applied, it should be done after the initial curing of the resin, and it should be in compliance with the construction fixation.

The Precautions For Carbon Fiber Panels

- The construction site must be kept clean to facilitate construction. The concrete surface must be clean, dry, and dust-free, and the construction site must maintain good ventilation.

- The temperature at the construction site needs to be controlled. Generally, the minimum construction temperature should not exceed minus 5 degrees Celsius, and the relative humidity should be less than 85%. Construction must not be carried out in the open on rainy days. Smoking is prohibited at the construction site and fire sources must be controlled.

- The carbon plate glue must be prepared in strict accordance with relevant specifications and stirred evenly. Air must be avoided during stirring to avoid foaming. If the carbon plate glue is not used up at one time, it needs to be resealed and packaged for storage.

- When pasting the carbon fiber board, if the carbon board glue accidentally drips on the skin, clean it immediately with acetone or alcohol. If it accidentally gets into your eyes, wash it with plenty of water and go to the hospital immediately.

Another notable feature of carbon fiber board is that it has high permeability to X-rays, so in the medical and health industry, it can be used as a medical panel. In addition, it can also be processed into various mechanical parts.

The above is the main function of carbon fiber board. If you want to know more about the content of carbon fiber board, you can read articles such as “Carbon Fiber Board Polishing Process” and “Causes of Carbon Fiber Board Hole Processing and Layering”. China Be-cu Prototype Material Technology Co., Ltd. is a china cnc machining company specializing in the production and machining of carbon fiber products. If you have any needs in this regard, please feel free to inquire.

ISO 9001 certified. BE-CU Prototype Offering CNC machining carbon fiber and other manufacturing services for carbon fiber marterial. Various capabilities include notching, labeling, drilling carbon fiber, grinding, laser cutting carbon fiber, finishing, plating, marking, CNC milling carbon fiber and turning carbon fiber.We stock high quality 3k carbon fiber sheet in a variety of thickness, types and finish. Its a great material used in applications where light weight and strength are needed such as drones. Unlike other workshops, we have no min order and are often filling orders with a single part. We also don’t make you pay for the full sheet and you only get charged for what is used. With a large selection of material, you should find everything you need to make your project come to life. We are also able to handle larger production runs and provide a competitive pricing. If we don’t have the material or finish you require, we are more the willing to look at bringing it in for you.

What Is Carbon Fiber?Carbon fiber is made of polyacrylonitrile (PAN) (or pitch, viscose) and other organic fibers by carbonization (removal of most elements except carbon) by pyrolysis method under inert gas at high temperature above 1,000 °C. Inorganic polymer fibers with a carbon content of more than 90%.

-

3D Printing Continuous Fibres

-

3D Printing Short Fibre Filled Wires

-

Laser Cutting Carbon Fiber Positioning Keyboard

-

Cnc Turning Industrial Copper-Aluminum Clad Carbon Fiber Machinery Parts

-

Carbon Fiber Luggage Tag Ornaments

-

Laser Cutting Carbon Fiber Guitar Shape Crafts

-

Laser Cutting Carbon Fiber Drone Rack

-

Cnc Milling Carbon Fiber Finger Buckle