In the realm of advanced materials, carbon fiber has emerged as a remarkable contender, revolutionizing industries ranging from aerospace to sports equipment. With its exceptional strength-to-weight ratio, durability, and versatility, carbon fiber has established itself as a preferred choice for composite materials. This article delves into the myriad reasons behind the widespread adoption of carbon fiber as a composite material, exploring its unique properties, manufacturing processes, applications across industries, and environmental implications.

View More Related Post:

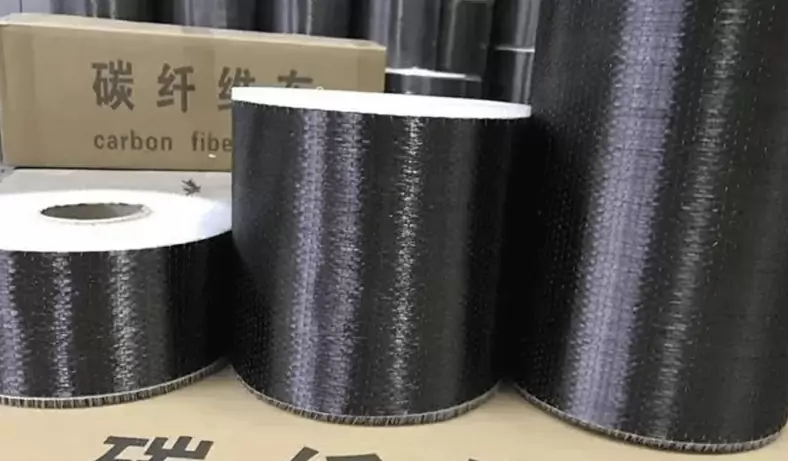

Understanding Carbon Fiber: The Basics

Carbon fiber is a composite material composed of extremely thin fibers, primarily consisting of carbon atoms. These fibers are bundled together to form a woven fabric, which is then impregnated with a polymer resin to create a composite material with superior properties. The remarkable strength of carbon fiber arises from the alignment of carbon atoms in a crystalline structure, forming strong carbon-carbon bonds. This atomic arrangement contributes to its exceptional mechanical properties and enables it to withstand high levels of stress and strain.

1. Exceptional Strength-to-Weight Ratio

One of the most compelling reasons for using carbon fiber as a composite material is its unparalleled strength-to-weight ratio. Carbon fiber composites are exceptionally lightweight while exhibiting remarkable strength, making them ideal for applications where weight reduction is crucial without compromising structural integrity. This characteristic is particularly valuable in aerospace and automotive industries, where minimizing weight directly translates to enhanced fuel efficiency, improved performance, and reduced emissions.

2. Superior Durability and Fatigue Resistance

Carbon fiber composites possess excellent durability and fatigue resistance compared to traditional materials like steel or aluminum. The unique arrangement of carbon atoms contributes to its high stiffness, preventing deformation and failure under heavy loads. Additionally, carbon fiber’s resistance to corrosion and chemical exposure makes it a favorable choice for applications in harsh environments, such as marine or chemical processing industries.

3. Tailorable Mechanical Properties

Manufacturers have the ability to engineer carbon fiber composites with specific mechanical properties by altering factors such as fiber orientation, resin type, and curing processes. This versatility allows for the customization of materials to suit a wide range of applications. Whether the goal is to enhance strength, stiffness, or impact resistance, carbon fiber can be tailored to meet these demands, underscoring its adaptability in various industries.

4. High-Temperature Tolerance

Carbon fiber exhibits remarkable thermal stability, retaining its mechanical properties at high temperatures that would cause other materials to degrade. This characteristic is especially critical in aerospace and aviation, where components experience extreme temperature fluctuations during flight. The ability to maintain structural integrity under such conditions enhances the reliability and safety of aircraft and spacecraft.

5. Electromagnetic Transparency

Another advantage of carbon fiber composites is their electromagnetic transparency. Unlike metal materials, carbon fiber does not interfere with electromagnetic signals, making it suitable for applications where signal transmission or reception is essential. This property has led to the use of carbon fiber in radio frequency (RF) equipment, radomes, and antennas.

6. Design Flexibility

Carbon fiber composites offer designers unprecedented freedom in shaping and styling products. The lightweight nature of carbon fiber allows for intricate and complex designs that might be impractical or impossible with traditional materials. This design flexibility has had a profound impact on industries like architecture, where carbon fiber is employed to create innovative and aesthetically pleasing structures.

Manufacturing Processes: Crafting Carbon Fiber Composites

The manufacturing of carbon fiber composites involves several key processes that contribute to their exceptional properties. These processes include:

1. Fiber Production

Carbon fiber begins as a precursor material, usually in the form of polyacrylonitrile (PAN) or pitch fibers. The precursor material undergoes a series of heat treatments in an oxygen-depleted environment to carbonize it. This process removes non-carbon elements and rearranges carbon atoms into the crystalline structure responsible for carbon fiber’s strength.

2. Weaving and Prepregging

The carbonized fibers are woven into a fabric, often in patterns like plain weave or twill weave, to create a textile-like material. This woven fabric is then impregnated with a polymer resin (prepreg) to enhance its mechanical properties and facilitate the shaping of the final product.

3. Layup and Curing

During the layup process, prepreg sheets are layered and positioned according to the desired orientation of the fibers. The layup is then subjected to heat and pressure in a curing process, where the resin undergoes polymerization, creating a solid and rigid composite structure.

4. Autoclave and Oven Curing

Curing can take place in an autoclave or an oven, both of which provide controlled conditions for the resin to cure properly. Autoclave curing subjects the composite to both heat and pressure, resulting in a higher quality product with fewer voids. Oven curing is a more cost-effective alternative and is suitable for certain applications.

5. Trimming and Finishing

After curing, excess material is trimmed and removed to achieve the final shape and dimensions of the product. Surface finishing processes, such as sanding and coating, are applied to enhance the appearance and protect the composite from environmental factors.

Applications Across Industries

Carbon fiber’s exceptional properties have paved the way for its utilization across a wide range of industries. Some notable applications include:

1. Aerospace and Aviation

The aerospace industry has extensively embraced carbon fiber composites due to their lightweight nature, high strength, and resistance to fatigue. Aircraft components such as wings, fuselage sections, and tail structures are increasingly being constructed using carbon fiber to improve fuel efficiency and reduce overall weight.

2. Automotive

In the automotive sector, carbon fiber is employed to create lightweight body panels, chassis components, and even entire frames. The use of carbon fiber in automobiles results in improved acceleration, handling, and fuel economy, while maintaining or enhancing safety standards.

3. Sports and Recreation

Carbon fiber has transformed the sports and recreation landscape by enabling the production of high-performance equipment. From bicycles and tennis rackets to golf clubs and hockey sticks, carbon fiber’s strength and flexibility contribute to enhanced performance for athletes and enthusiasts.

4. Wind Energy

The wind energy industry benefits from carbon fiber’s lightweight and durable properties in the production of turbine blades. Carbon fiber-reinforced blades are capable of withstanding the stresses of wind forces while optimizing energy capture.

5. Medical Devices

Carbon fiber is increasingly finding applications in medical devices, such as orthopedic implants, prosthetics, and surgical instruments. Its biocompatibility, lightweight nature, and customizable mechanical properties make it a valuable material in the medical field.

6. Construction and Infrastructure

Carbon fiber’s design flexibility and high strength make it a valuable resource in architectural applications. It is used to reinforce concrete, create lightweight yet robust structures, and even restore historical buildings.

7. Consumer Goods

From luxury goods to electronics, carbon fiber’s aesthetic appeal and durability have made it a sought-after material in the production of consumer goods. Items like watches, wallets, and phone cases benefit from carbon fiber’s combination of style and functionality.

Environmental Implications and Sustainability

While carbon fiber boasts remarkable advantages, it is essential to address its environmental impact. The production of carbon fiber involves energy-intensive processes, including the carbonization of precursor materials and the curing of composites. Additionally, the disposal of carbon fiber composites can be challenging due to their non-biodegradable nature.

Efforts are being made to enhance the sustainability of carbon fiber production. Research is focused on developing alternative precursors, exploring recycling methods, and optimizing manufacturing processes to reduce energy consumption and waste generation. As these initiatives progress, carbon fiber’s environmental footprint is expected to decrease, making it a more viable option for eco-conscious industries.

Conclusion

The utilization of carbon fiber as a composite material has transformed industries and redefined the possibilities of design and engineering. Its exceptional strength-to-weight ratio, durability, and customizable properties have led to its adoption in applications as diverse as aerospace, automotive, sports, and architecture. As technology advances, carbon fiber’s production processes are becoming more sustainable, mitigating some of the environmental concerns associated with its usage. With ongoing research and innovation, carbon fiber is poised to continue shaping the future of materials science and revolutionizing the way we create, build, and explore.

ISO 9001 certified. BE-CU Prototype Offering CNC machining carbon fiber and other manufacturing services for carbon fiber marterial. Various capabilities include notching, labeling, drilling carbon fiber, grinding, laser cutting carbon fiber, finishing, plating, marking, CNC milling carbon fiber and turning carbon fiber.We stock high quality 3k carbon fiber sheet in a variety of thickness, types and finish. Its a great material used in applications where light weight and strength are needed such as drones. Unlike other workshops, we have no min order and are often filling orders with a single part. We also don’t make you pay for the full sheet and you only get charged for what is used. With a large selection of material, you should find everything you need to make your project come to life. We are also able to handle larger production runs and provide a competitive pricing. If we don’t have the material or finish you require, we are more the willing to look at bringing it in for you.

What Is Carbon Fiber?Carbon fiber is made of polyacrylonitrile (PAN) (or pitch, viscose) and other organic fibers by carbonization (removal of most elements except carbon) by pyrolysis method under inert gas at high temperature above 1,000 °C. Inorganic polymer fibers with a carbon content of more than 90%.

-

3D Printing Continuous Fibres

-

3D Printing Short Fibre Filled Wires

-

Laser Cutting Carbon Fiber Positioning Keyboard

-

Cnc Turning Industrial Copper-Aluminum Clad Carbon Fiber Machinery Parts

-

Carbon Fiber Luggage Tag Ornaments

-

Laser Cutting Carbon Fiber Guitar Shape Crafts

-

Laser Cutting Carbon Fiber Drone Rack

-

Cnc Milling Carbon Fiber Finger Buckle