Cnc Machining Aluminum 6061 Alloy Specialist

Aluminum 6061 is the most used aluminum alloy for machining and the most versatile and economical. It has good resistance to corrosion and welds well, although it must be taken into account that aluminum loses almost 30% of the breaking load in the welded area. It is an alloy that is halfway between the mechanical characteristics of 6063 and the alloys of the Aluminum-Copper (2000 Series) and Aluminum-Zinc (7000 Series) families. The quality of the anodizing is very good.They are used in:Aviation, automotive components, bicycle components, food containers, etc.

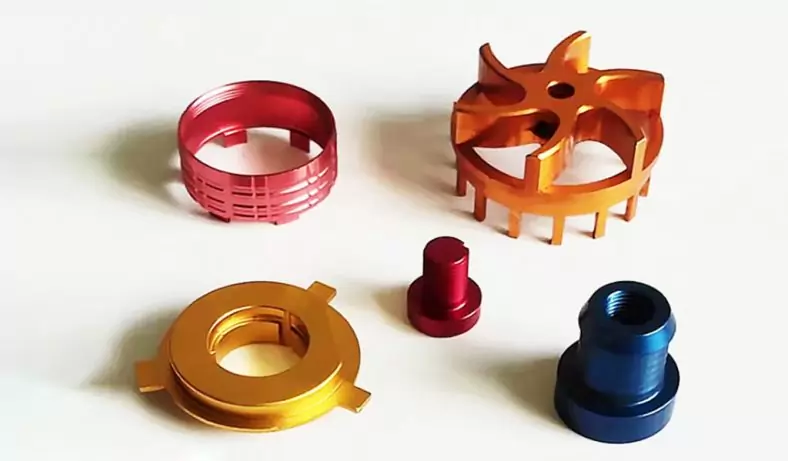

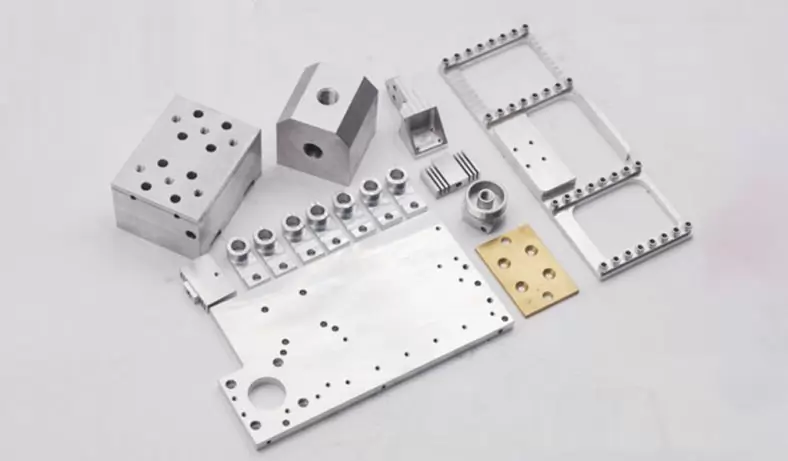

3,4,5-axis precision CNC machining services for 6061 aluminum alloys. Capable of machining parts up to 4 in. circumscribed dia., 0.040 in. minimum wall thickness and +/-0.002 in. tolerance. Milling, cutting, drilling, punching, welding and tapping services provided. Deburring and grinding services also offered. Prototype and low to medium volume production runs. AutoCAD and SolidWorks® files accepted.

Why Choose Our Aluminum 6061 Cnc Machining Service?

- Save time and money for your aluminum 6061 project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of aluminum grades and alloy materials can be machined

- Custom complex aluminum cnc machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

Top Aluminum 6061 Machined Parts & Case Studies

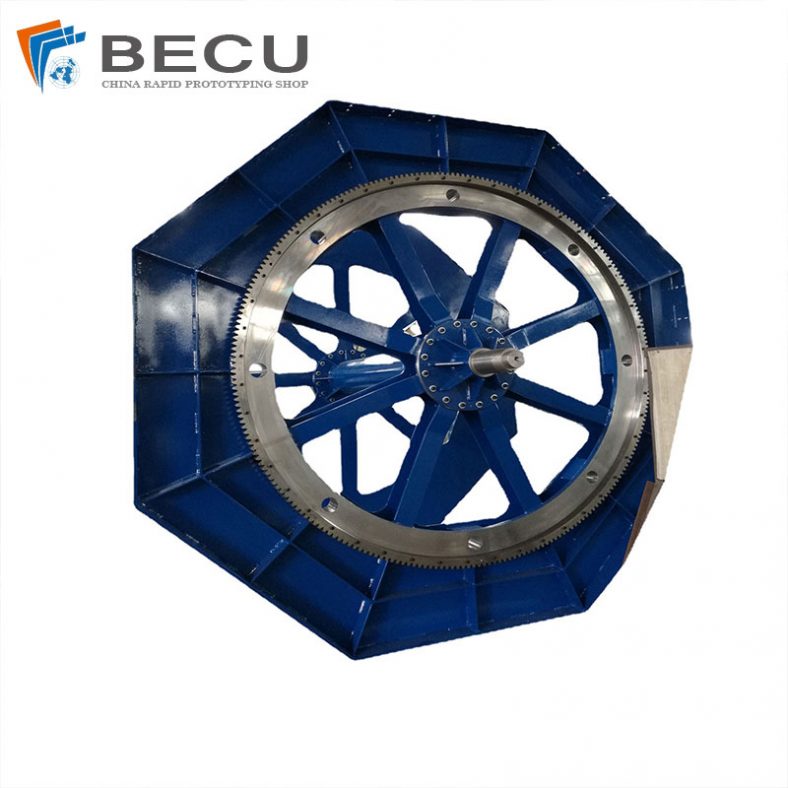

Cnc Machining processes such as cnc milling, turning and swiss machining are today considered the most economic way to make aluminum 6061 prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes 3d printing is the only option. Our company has rich experience making aluminum 6061 concept models and precise functional components. Understanding the properties of different aluminum alloy, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on aluminum alloy. Be-cu prototyping company provides a range of solutions for the machining of aluminum parts.

-

CNC Machining For Camera L Bracket

-

Welding CNC Machining 5M Drum For Centrifugal Fan

-

Large Machining Micro-Automation Robots Joint

-

CNC Machining 6061-T1 Electromagnetic Clutch Parts

-

Precision Machining 6061-T1 Automobile Motor Prototype

-

Precision Machining Security Door Lock Guard Housing

-

Turn-Mill Machining 6061-T1 Bicycle Trim Gasket

-

Precision 5 Axis Machining Aluminum 6061 Aerospace Parts

-

5 Axis CNC Milling Aluminum 6061 Led High Bay Lighting Parts

-

CNC Machined Rotary Head Aluminum Parts

-

Turning And Milling Of Valve Body Parts

-

CNC Machining Non-standard Aluminum Tube Customization

What Is Aluminum Alloy 6061?

6061 aluminum is a thermally strengthened alloy with good formability, weldability, machinability and moderate strength. Good workability remains after annealing.

The Define Of Aluminum 6061

6061 aluminum alloy is a high-quality aluminum alloy product produced by heat treatment and pre-stretching process.

6061 aluminum is a thermally strengthened alloy with good formability, weldability, machinability and moderate strength. Good workability remains after annealing. The main alloying elements of 6061 aluminum are magnesium and silicon to form the Mg2Si phase.

If contained in a certain amount of manganese and chromium, the undesirable effects of iron can be neutralized; small amounts of copper or zinc are sometimes added to increase the strength of the alloy without significantly reducing its corrosion resistance; there are small amounts of conductive material to offset titanium and iron Adverse effects on electrical conductivity; zirconium or titanium can refine the grains and control the recrystallized structure; in order to improve machinability, lead and bismuth can be added. Mg2Si dissolves in aluminum,

6061 aluminum is a thermally strengthened alloy with good formability, weldability, machinability and moderate strength. Good workability remains after annealing. The main alloying elements of 6061 aluminum are magnesium and silicon to form the Mg2Si phase. If contained in a certain amount of manganese and chromium, the undesirable effects of iron can be neutralized; small amounts of copper or zinc are sometimes added to increase the strength of the alloy without significantly reducing its corrosion resistance; there are small amounts of conductive material to offset titanium and iron Adverse effects on electrical conductivity; zirconium or titanium can refine the grains and control the recrystallized structure; in order to improve machinability, lead and bismuth can be added. Mg2Si dissolves in aluminum,

The main alloying elements of 6061 aluminum are magnesium and silicon, forming the Mg2Si phase. If contained in a certain amount of manganese and chromium, the undesirable effects of iron can be neutralized; small amounts of copper or zinc are sometimes added to increase the strength of the alloy without significantly reducing its corrosion resistance; there are small amounts of conductive material to offset titanium and iron Adverse effects on electrical conductivity; zirconium or titanium can refine the grains and control the recrystallized structure; in order to improve machinability, lead and bismuth can be added. Mg2Si is solid-dissolved in aluminum, which makes the alloy have artificial age hardening function. The main alloying elements in 6061 aluminum are magnesium and silicon, with medium strength and good corrosion resistance.

It neutralizes the adverse effects of iron; small amounts of copper or zinc are sometimes added to increase the strength of the alloy without significantly reducing its corrosion resistance; conductive materials contain small amounts of copper to counteract the adverse effects of titanium and iron on conductivity ;

Zirconium or titanium can refine the grains and control the recrystallization structure; in order to improve the machinability, lead and bismuth can be added. Mg2Si is solid-dissolved in aluminum, which makes the alloy have artificial age hardening function. The main alloying elements in 6061 aluminum alloy are magnesium and silicon, which have medium strength, good corrosion resistance, weldability and good oxidation effect.

Magnesium-aluminum 6061 has excellent cnc machining performance, good corrosion resistance, high toughness, no deformation after cnc machining, easy to color and film, and excellent oxidation effect.

It belongs to Al-Mg-Si alloy with medium strength, good plasticity and excellent corrosion resistance. In particular, it has no tendency to stress corrosion cracking, excellent weldability, good corrosion resistance and cold workability. It is a promising alloy with a wide range of applications. It can be anodized and colored, and can also be painted with enamel, which is suitable for building decoration materials. It contains a small amount of Cu, so the strength is higher than 6063, but the quench sensitivity is also higher than 6063. Air quenching cannot be achieved after extrusion, and re-solution treatment and quenching aging are required to obtain higher strength.

The Classification Of Aluminum 6061

6061-T651 is the main alloy of 6061 aluminum alloy. Although it is not as strong as the 2XXX series or 7XXX series, its magnesium silicon alloy has many characteristics. It has excellent processing performance, excellent welding characteristics and electroplating performance, and good resistance. Corrosion resistance, high toughness, no deformation after processing, dense material without defects, easy to polish, easy to color and film, excellent oxidation effect and other excellent characteristics.

- The application of adhesive strips is widely used in decoration, packaging, construction, transportation, electronics, aviation, aerospace, weapons and other industries.

- Aluminum used in aerospace is used in the manufacture of aircraft skins, fuselage frames, beams, rotors, propellers, fuel tanks, wall panels and landing gear struts,

- Aluminum for transportation is used for automobiles, subway cars, railway passenger cars, high-speed passenger cars, doors and windows, shelves, body structural material parts of automobile engines, air conditioners, radiators, body panels, wheel hubs and ship materials.

- Aluminum for Packaging All-aluminum easy-open cans are mainly used as metal packaging materials in the form of sheets and foils, and are made into cans, lids, bottles, barrels, packaging foils, etc. Widely used in the packaging of beverages, food, cosmetics, pharmaceuticals, cigarettes, and industrial products. 5. Aluminum for printing is mainly used to make PS plates. Aluminum-based PS plate is a new type of material for automatic plate-making and printing in the printing industry. 6. Aluminum alloys for architectural decoration are widely used in architectural frames, doors and windows, ceilings, decorative surfaces, etc. due to their good corrosion resistance, sufficient strength, excellent process performance and welding performance. Such as various building doors and windows, aluminum profiles for curtain walls, aluminum curtain wall panels, profiled plates, checkered plates, color-coated aluminum plates, etc. Seven, aluminum materials for electronic appliances are mainly used in various fields such as busbars, overhead lines, conductors, electrical components, Refrigerator, air conditioner and cables. Specifications: round bar,

6061 Aluminum Alloy Element

The main alloying elements of 6061 aluminum alloy are magnesium and silicon, forming the Mg2Si phase. If contained in a certain amount of manganese and chromium, the undesirable effects of iron can be neutralized; small amounts of copper or zinc are sometimes added to increase the strength of the alloy without significantly reducing its corrosion resistance; there are small amounts of conductive material to offset titanium and iron Adverse effects on electrical conductivity; zirconium or titanium can refine the grains and control the recrystallized structure; in order to improve machinability, lead and bismuth can be added. Mg2Si is solid-dissolved in aluminum, which makes the alloy have artificial age hardening function. The main alloying elements in 6061 aluminum alloy are magnesium and silicon, with medium strength,

The Characteristics Of Magnesium-Aluminum Alloy 6061

Magnesium-aluminum 6061-T651 is the main alloy of the 6-series alloy, and it is a high-quality aluminum alloy product that has undergone heat treatment and pre-stretching. It has excellent characteristics such as easy coloring and film formation and excellent oxidation effect.

Main use: Widely used in various industrial structural parts that require certain strength and high corrosion resistance, such as the manufacture of trucks, tower buildings, ships, trams, railway vehicles, etc.

The Typical Application Of 6061

Representative applications include aerospace fixtures, electrical fixtures, communications, and are also widely used in automated mechanical parts, precision machining, mold manufacturing, electronics and precision instruments, SMT, PC board solder carriers, etc.

Aluminum Alloy Basic State Code

- F Free machining state is suitable for products with special requirements for work hardening and heat treatment conditions during the forming process. The mechanical properties of the product in this state are not regulated (uncommon)

- O Annealed Condition For processed products sufficiently annealed for minimum strength (occasionally)

- H Work-hardened state Applies to products whose strength is increased by work-hardening. Work hardened products may (or may not) undergo additional heat treatment to reduce strength (generally non-heat treated reinforcements)

- W The solution heat treatment state is an unstable state and is only suitable for alloys that are naturally aged at room temperature after solution heat treatment. A code for this status only indicates that the product is in the natural aging stage (uncommon)

- The T heat treatment condition (different from the F, O, H condition) is used after heat treatment, after work hardening (or unworked) to achieve a stable product. The T code must be followed by one or more Arabic numerals (usually heat-treated reinforced materials). The state code behind our common non-heat-treated reinforced aluminum alloys is generally the letter H plus two digits. Such as 1100 H14. The meaning of the following status codes is briefly described below.

The letter H is usually followed by two digits: the first digit indicates the method of work hardening. The first number after the H is: 1, 2, 3, 4

That is, H1* H1* means simple work hardening

- H2* H2* means work hardening and incomplete annealing

- H3* H3* means work hardening and stabilization

- H4* H4* means work hardened and painted

The second number indicates the degree of hardening achieved by the material.

The second number after the H is: 1, 2, 3, 4, 5, 6, 7, 8, 9

H1 Hardness between 0 and 2 H2 1/4 Hard H3 Hardness between 2 and 4 H4 1/2 Hard H5 Hardness between 4 and 6 H6 3 /4 Hard H7 Hardness between 6 and 8 H8 Full Hard H9 Super Hard (H followed by three numbers is not much, only a few. H111 indicates that a moderate amount of work hardening has been carried out after final annealing .H112 indicates products suitable for hot forming. H116 indicates 5 products made of alloys with magnesium content ≥ 4.0% **.)

The state code behind our common heat-treated aluminum alloys is generally the letter T plus one or more Arabic numerals to indicate the subdivision state of T. Add 0-10 Arabic numerals after T to indicate the subdivision state (called TX state). The number after the T indicates the heat treatment procedure of the product. After T0 solution heat treatment, naturally aged, then cold worked condition. Suitable for products with increased strength through cold working.

T1 is cooled by a high temperature forming process, and then naturally aged to a basically stable state. It is suitable for products that are not cold processed after cooling by high temperature forming process (straightening and leveling can be carried out, but the mechanical performance limit is not affected). T2 is cooled by a high temperature forming process, and then naturally aged to a basically stable state after cold working. It is suitable for products that have been cold worked, straightened, straightened, and cooled by a high temperature forming process to increase their strength. T3 cold working after solution heat treatment, and then naturally aged to a substantially stable state. It is suitable for products that are cold worked, straightened and straightened after solution heat treatment to improve strength. After T4 solution heat treatment, it is naturally aged to a basically stable state. It is suitable for products that are not subjected to cold working after solution heat treatment (straightening and leveling can be carried out, but the mechanical properties are not affected), and then natural aging treatment is carried out. T5 The state of artificial aging after cooling by high temperature forming process. It is suitable for products that have not been cold-worked (can be straightened and leveled, but does not affect the limit of mechanical properties). Artificial aging state after T6 solution heat treatment. It is suitable for products that are not subjected to cold working after solution heat treatment (straightening and leveling can be carried out, but the mechanical properties are not affected), and then artificial aging treatment is carried out.

T7 Artificial aging state after solution heat treatment. It is suitable for products whose strength exceeds the highest peak point of the aging curve when artificially aged to obtain some important characteristics after solution heat treatment.

T8 The state of artificial aging after cold working after solution heat treatment. Suitable for cold working, straightening, leveling to increase the strength of the product.

T9 Artificially aged state after cold working after solution heat treatment. Suitable for products that have been cold worked to increase product strength.

After the T10 is cooled by the high temperature forming process, it is cold worked and then artificially aged. Suitable for cold worked, or straightened or leveled products to increase the strength of the product. T status and TXXX status (except stress relief status) Add one more Arabic numeral after the TX status code (called TXX status), or add two Arabic numerals (called TXXX status), indicating that the product characteristics have changed significantly (such as mechanical properties, corrosion resistance, etc.) the processing state of the specific process.

T42 is suitable for products whose natural aging reaches a sufficiently stable state after solid solution heat treatment in O or F state, and is also suitable for products whose mechanical properties reach T42 state after heat treatment of processed products in any state by the buyer. T62 is suitable for products that enter artificial aging after O or F state solution heat treatment, and also applies to products whose mechanical properties reach T62 state after heat treatment of processed products in any state by the buyer.

T73 is suitable for products that have reached the specified mechanical properties and stress corrosion resistance after aging after solution heat treatment.

The definition of T74 is the same as that of T73. The tensile strength of this state is greater than that of the T73 state, but less than that of the T76 state.

The definition of T76 is the same as T73. The tensile strength of this temper is higher than that of the T73 and T74 tempers, and the stress corrosion cracking resistance is lower than that of the T73 and T74 tempers. However, its resistance to exfoliation corrosion is still better.

T7X2 is suitable for products whose mechanical properties and corrosion resistance reach T7X state after solution heat treatment and artificial aging treatment in O or F state.

T81 is suitable for products that have undergone solution heat treatment. After about 1% cold working deformation to increase the strength, artificial aging treatment is carried out. T87 is suitable for products that have undergone solution heat treatment. After about 7% cold working deformation to increase the strength, artificial aging treatment is carried out. “Stress Relief Status” Add “51” or “510” or “511” or “52” or “54” after the above TX or TXX or TXXX status code to indicate the product status code that has undergone stress relief treatment.

TX51 TXX51 TXXX51 is suitable for thick plates, rolled or cold rolled bars and die forgings, forged rings or rolled rings that are drawn to specified amounts after solution heat treatment or cooling during high temperature forming. These products no longer straighten after being stretched. The permanent deformation of thick plates is 1.5% to 3%; the permanent deformation of rolled or cold rolled bars is 1% to 3%; the permanent deformation of forged or rolled ring die forgings is 1% to 5%. The permanent deformation of extruded bars, profiles and pipes is 1% to 3%; the permanent deformation of drawn pipes is 1.5% to 3%.

TX511 TXX511 TXXX511 is suitable for extruded bars, profiles and tubes and drawn tubes that are solution heat treated or cooled by high temperature forming processes and stretched to specified amounts. These products can be slightly straightened after stretching to meet standard tolerances. TX52 TXX52 TXXX52 is suitable for cooling in solution heat treatment or high temperature forming process, compression to relieve stress, thus producing 1%~5% permanent deformation products. TX54 TXX54 TXXX54 is suitable for die forgings that are cold formed in final forging dies for stress relief. T6, solution treatment (quenching), artificial aging T62, after annealing or F state solution treatment, artificial aging T61 is a special heat treatment state, and its strength is required to be lower than T6.

The Chemical Composition Of Aluminum 6061

- Unit: %

- Copper Cu: 0.15~0.4

- Manganese Manganese: 0.15

- Magnesium: 0.8~1.2

- Zinc: 0.25

- Chromium Cr: 0.04~0.35

- Titanium: 0.15

- Silicon Si: 0.4~0.8

- Aluminum Al: Allowance

The Mechanical Properties Of Aluminum 6061

- Tensile strength σb (MPa): ≥180

- Yield strength σ0.2 (MPa): ≥110

- Elongation δ5 (%): ≥14

- Sample size: diameter≤150

- Brinell hardness HB: 95-100

- Note: Longitudinal mechanical properties of bars at room temperature

Aluminum Sheet Specification Calculation

Aluminum plate material. Internationally, aluminum materials with a thickness of more than 0.2mm, less than 500mm, a width of more than 200mm, and a length of less than 16m are called aluminum plates or aluminum plates. Aluminum foil below 0.2mm. Strips or strips within 200mm width (of course with the advancement of larger equipment there are more and more strips with a maximum width of 600mm).

Aluminum rod: diameter: 3-500mm aluminum tube, thickness: 2-500mm Pan Zhu’s theoretical calculation formula for aluminum tube, aluminum plate and aluminum rod. (Note: there is an error with the actual weight, the unit of size is mm) Aluminum plate weight (kg) = 0.0000028 × thickness × width × long aluminum tube weight (kg) = 0.00879 × wall thickness × (outer diameter – wall thickness) × length aluminum rod Weight calculation formula (kg) = diameter × diameter × length × 0.0000022