Cnc Machining Aluminum 2024 Alloy Specialist

Aluminum 2024 is used in applications that require a high strength-to-weight ratio as well as good fatigue resistance. Corrosion resistance is poor. It doesn’t weld well. And it is not very suitable for anodizing.They are used in: Various applications such as aeronautics, machine tools, dies, etc.

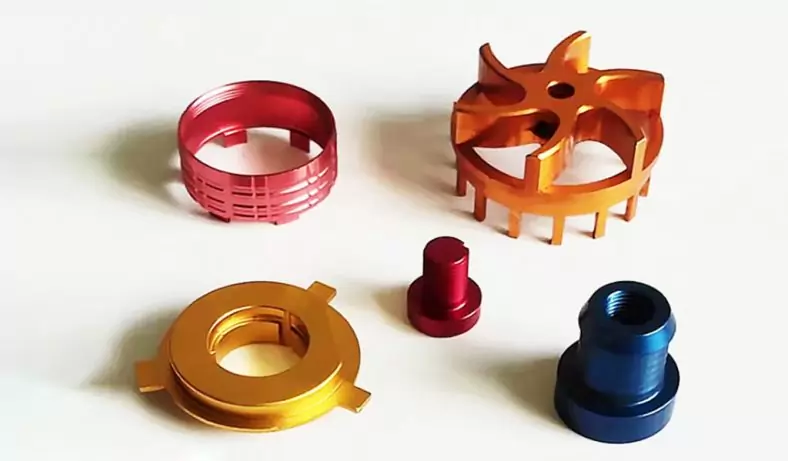

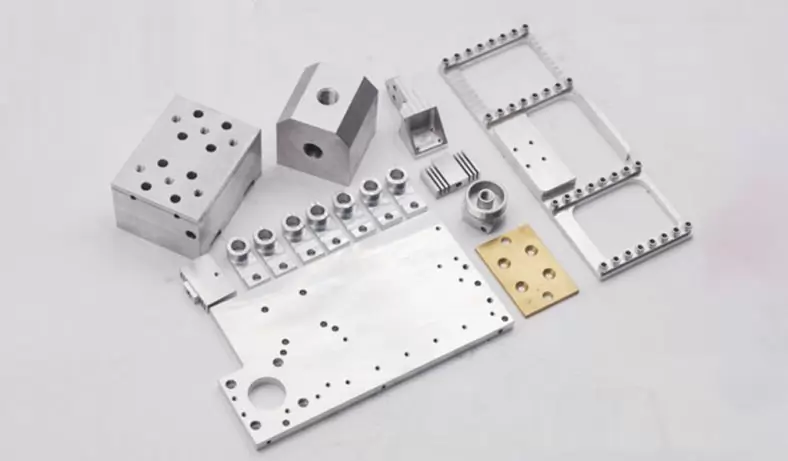

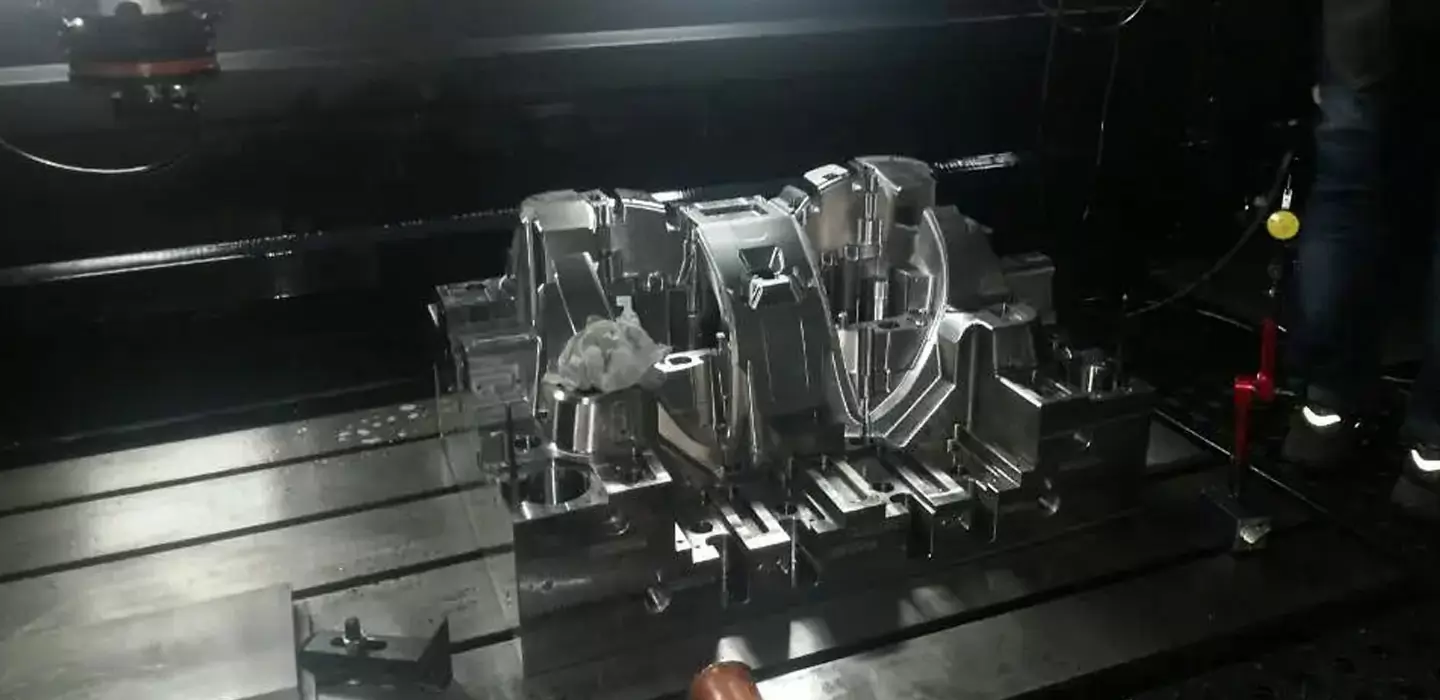

BE-CU.COM Is ISO 9001:2015 certified precision CNC aluminum 2024 machining services including aluminum 2024 CNC milling and aluminum 2024 turning services. Boring, contouring, counterboring, countersinking, decking, drilling, facing, pocketing, profiling, reaming, slitting, slotting, splining, tapping, thread milling, 2.5 D machining, parting/cutting, contour, form, taper and straight turning, external and internal threading, grooving and knurling services are available. Capabilities include prototyping, low and high volume production, short and long run production and assembly.

Why Choose Our Aluminum 2024 Cnc Machining Service?

- Save time and money for your aluminum 2024 project but quality guaranteed.

- High productivity, outstanding efficiency and high accuracy

- A wide range of aluminum grades and alloy materials can be machined

- Custom complex aluminum cnc machined parts and components at specific tolerances

- High speed machining for prototyping and low to high volume production runs

Certifications & Quality Machining

- ISO 9001:2015 certified

- Fully compliant with the exacting requirements of our customers

- Compliance in DFARS materials sourcing requirements

- Strict compliance with PPAP and Process

- FMEA for automotive customers

- Skilled in KanBan and CMM Inspection and inventory management systems

- ITAF 16949 certified

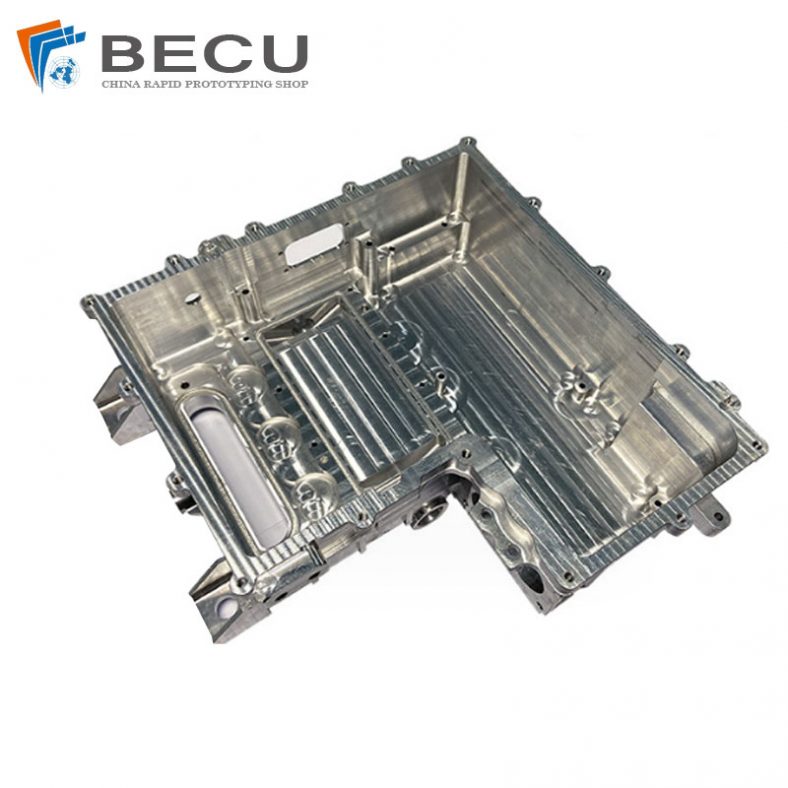

Top Aluminum 2024 Machined Parts & Case Studies

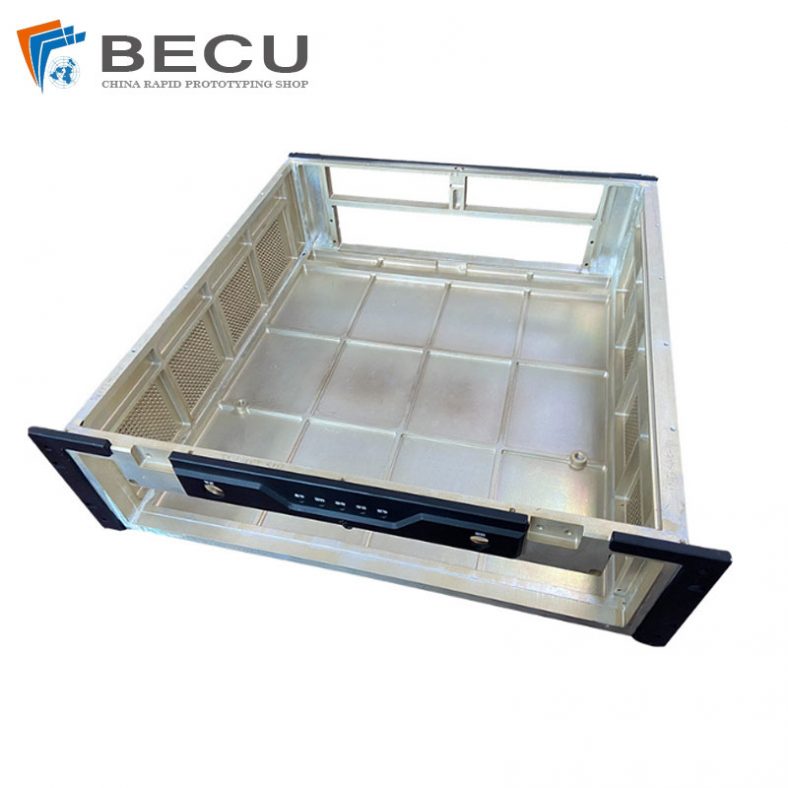

Cnc Machining processes such as cnc milling, turning and swiss machining are today considered the most economic way to make aluminum 2024 prototypes. Sometimes, however, certain non-machiningable materials are needed, and sometimes 3d printing is the only option. Our company has rich experience making aluminum 2024 concept models and precise functional components. Understanding the properties of different aluminum alloy, with lots of testing and experimentation with pre-heating, tool paths and other factors, we are able to minimize deformation on aluminum alloy. Be-cu prototyping company provides a range of solutions for the machining of aluminum parts.

-

5 Axis Machining Aluminum-Magnesium Alloy Water Aerator Impeller

-

Precision Machining 6063 Aluminum Military Computer Server Chassis

-

CNC 6063 Aluminum Automotive Motor End Cover

-

Precision CNC Machining Unmanned Aerial Vehicle Motor Base

-

Metal CNC Machining Motor Front And Rear Covers

-

CNC Machining For Camera L Bracket

-

Precision Machining Security Door Lock Guard Housing

-

Custom Electron Optical Instrument Sight Bracket

-

Customized Optical Instrument Projector Components By 4 Axis Mill

-

Precision Milling Astronomical Telescope Wide-angle Lens Eyepiece Element

-

Custom Cnc Milling Machining Aluminum Alloy 2024 Parts

-

Five-Axis Precision Cnc Milling Automation Parts