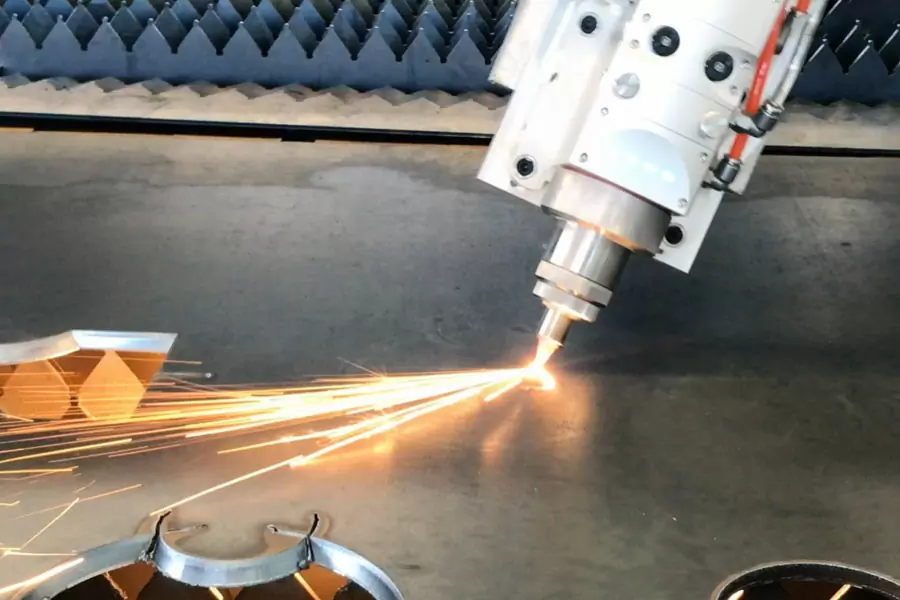

Steel Laser Cutting

Alloy Steel is a very versatile steel and are among some of the strongest materials due to alloying steel with a variety of elements. Elements added in low quantities of less than around 5 wt.% tend to improve mechanical properties, for example increasing hardenability and strength, whereas larger additions of up to 20 wt.% increase corrosion resistance and stability at high or low temperatures.

Alloy steel comes in a range of forms including plates, sheets, bars, tubing, pipes and wire products. Alloy steel can be fabricated for any necessary characteristics including strength, hardness, toughness, corrosion and wear resistance.

Our steel laser cutting services enable you to create custom alloys steel parts for many applications across industries such as energy, medical technology, agriculture, industrial automation, machinery, robotics, and construction. With us, your steel parts are machined directly from the information of a CAD file and a technical drawing, both of which can be uploaded onto our quote.

The Alloy Steel Grades Of Metal Laser Cutting

The application of laser cutting spans several materials. Choosing the right material for your project can be tricky, usually involving several factors. However, selecting the material to use, steel, in this case, is just the first step. You still have to choose from the different grades available.

The properties of the steel grades inform their respective use for specific machining projects. Here are some of the commonest grades and their properties.

- Steel 1008:Moderate strength and low-stress applications.

- Steel 1018:Plain low carbon steel, poor machinability but good formability and weldability. Case harden only

- Steel 1045:Strength, impact resistance and higher tensile strength.

- Steel 1137:Higher carbon, higher strength, direct hardening

- Steel 11L37:Strength and machinability

- Steel 11L41:Strength and hardness and a more uniform surface hardness

- Steel 12L14:Designed for excellent machinability. Case hard only

- Steel 1215:Designed for good machinability. Case harden only

- Steel 4130:Strength, toughness, and fatigue resistance

- Steel 4140:Popular general-purpose alloy. Direct hardening

- Steel 41L40:Designed for better laser cutting w/lead additive; direct hardening

- Steel 8620:.55% Ni, .50% Cr, .20% Mo, heat treatable and case hardening

- Steel 52100:Very high 1% carbon, .25% Ni,1.4% Cr, .08% Mo

Steel Laser Cutting Services – CNC Laser Cut Steel Parts Suppliers & Manufacturer

Laser Cutting is an essential process in many steel parts manufacturing operations. There used to be a time when the process was entirely manual, but that was highly effort and time-intensive. Nowadays, steel laser cutting services are automated, and one such application is fiber laser cut. This automated process has become very common in the manufacturing industry because of its speed, precision, and production efficiency. Several materials are compatible with Laser Cutting, and steel is no exception. In fact, laser cut steel parts are one of the most popular for custom steel parts and prototypes.Laser Cutting steel components is one of the most popular services in China. Our team of experienced engineers and technicians are experts in laser cut steel components and can quickly optimize your product design to meet your specific requirements.With decades of experience, we can help you choose the best steel for your project and produce high-quality steel components that meet your specifications.

Our Steel Laser Cutting Capabilities

Precision Steel Laser Cutting services for the aerospace, automotive, cosmetics, food, marine, medical, telecommunications, textile and water management industries.Tolerance ranges up to +/-0.01 in. Other capabilities include milling, drilling, boring, turning, threading, broaching and profiling. Engineering and surface grinding services are also provided. Metal straightening, sawing, magnetic particle inspection, heat treating and annealing additional services are also available. Prototype and low to high volume production offered. Lean manufacturing capable. Blanket orders, CAD/CAM and SolidWorks® files accepted.

Secondary services include machining, aqueous cleaning, coping, beading, drilling, flattening, flaring, notching, piercing, slotting, swaging, threading, bar coding, brush & tumble deburring, chamfering, JIT-SPC, plating, powder coating, reverse engineering, packaging & assembly. ISO certified QC & inspections.

Why Use Our Steel Laser Cutting Services

The Top 6 Reasons:

- No MOQ:One-off Steel laser cutting prototype part or large quantity parts. No matter the size of your order, we can handle it.

- Industry-best pricing:Our custom steel sheet metal fabrication process and technology allow us to offer competitive prices that can match any offer.

- Fast delivery:We have 44 laser cutter and other sheet metal fabrication equipment at our disposal and can take your project from engineering design to delivery faster than our competitors.

- Experienced Engineers:Our team has years of experience in a wide range of industries and can handle even the most challenging projects.

- High-precision and tight tolerance:We service the automotive,medical and electronic industries and can produce parts with tight tolerances. We also use precise tool holders and tools to ensure optimal precision and accuracy.

- Wide range of coatings & finishes:We can offer a wide range of coatings and finishes for your parts depending on your project requirements.

Combine With Other Steel Manufacturing Processes

Most laser shops will only give quotations for laser cutting as a standalone process. But when the quantity of new parts goes up to hundreds or more, you need a better solution for the best results. For some of these conplex parts, it is better not to cut them from a solid block at all, but to use tool-based fabrication or edm cutting assisted by milling.

When making Steel cutting parts, Be-cu.com offers several ways to combine precision laser cutting with other manufacturing processes in order to create more complex parts that can be made in large quantities. These process combinations can maximize the functionality of Steel while still enjoying the benefits of other production processes.

CNC Bending,Welding, Laser Engraving, Metal Etching,Precision machining, stamping, EDM, Wire Cutting and more can all be complemented with laser cutting to make better Steel components. No matter the test and no matter what properties are required.

Our Case Studies Gallery Of Steel Laser Cutting

Steel laser cutting produces durable, end-use steel parts with a wide selection of steel materials and finishes that meet your specifications, for a variety of industries like: Automotive, Medical device, Aerospace, electronics, energy, robotics and more.Compared with traditional laser cutting companies, we have a large amount of precision machines, so we can do precision post-machining in house.Send your CAD files or inquiry to us, a fast, free online laser cutting quote of required Steel components will be back. Get your Steel Laser Cut Parts into fabrication in the shortest time.