In the realm of modern manufacturing and product development, technological advancements have ushered in a new era of innovation and efficiency. Three terms that have become synonymous with this transformation are 3D printing, additive manufacturing, and rapid prototyping. While these terms are often used interchangeably, they each represent distinct processes and technologies with unique applications and capabilities.

This article aims to provide a comprehensive comparison of 3D printing, additive manufacturing, and rapid prototyping, shedding light on their origins, underlying principles, and the industries they serve. By delving deep into these technologies, we hope to clarify their differences and help you make informed decisions for your specific needs.

View More Articles:

Section 1: Understanding the Basics

1.1. What is 3D Printing?

3D printing, also known as additive printing or stereolithography, is a process that creates three-dimensional objects from a digital file by adding material layer by layer. The concept of 3D printing dates back to the early 1980s when Chuck Hull invented the first stereolithography apparatus (SLA) machine. Since then, 3D printing has evolved significantly and found applications in various fields, including aerospace, healthcare, automotive, and consumer goods.

1.2. The Essence of Additive Manufacturing

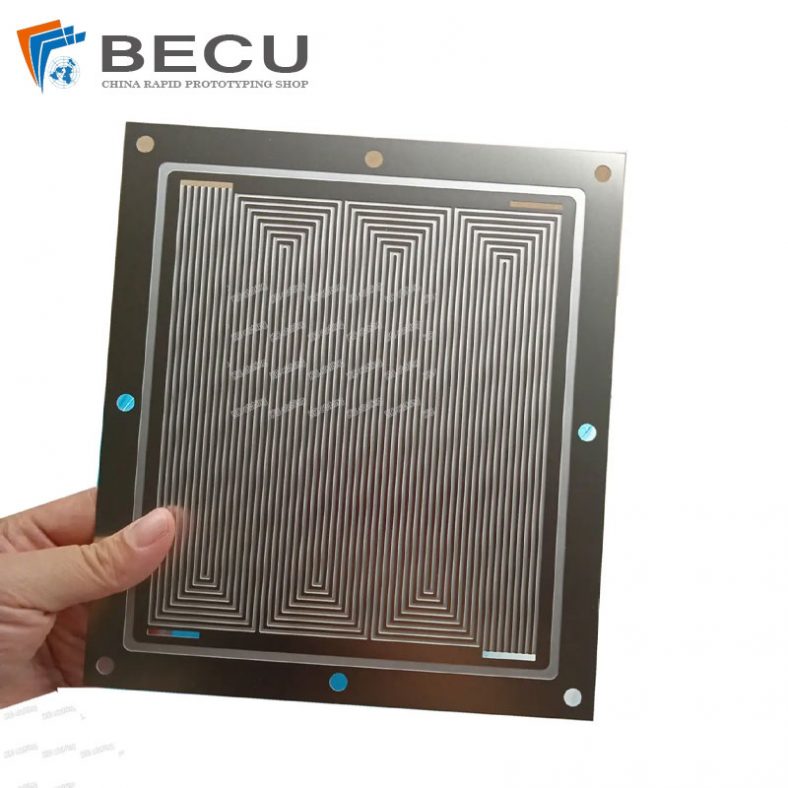

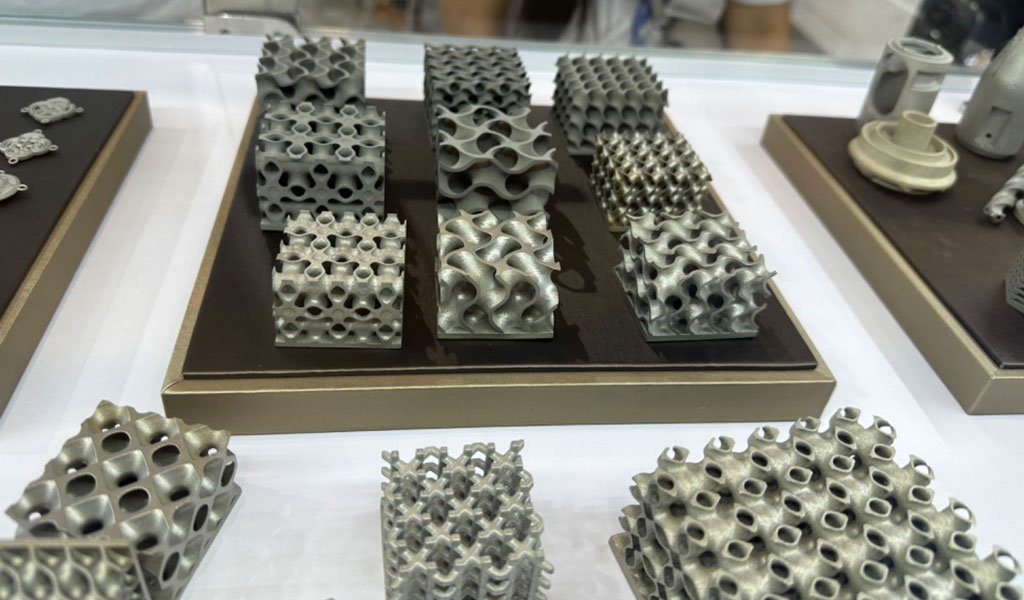

Additive manufacturing (AM), a broader term encompassing 3D printing, refers to the process of creating objects by adding material layer by layer, typically using a computer-aided design (CAD) model. Additive manufacturing is not limited to one specific technology but includes various techniques such as fused deposition modeling (FDM), selective laser sintering (SLS), and electron beam melting (EBM). It has revolutionized production processes, offering cost-effective and efficient solutions for complex part manufacturing.

1.3. The Role of Rapid Prototyping

Rapid prototyping is a subset of additive manufacturing that focuses on quickly creating prototypes or models to test and validate product designs. It’s primarily used in product development and engineering to accelerate the design iteration process. Rapid prototyping technologies share similarities with 3D printing, but they prioritize speed and ease of use for producing functional prototypes and mock-ups.

Section 2: Key Differences

2.1. Materials and Processes

One of the fundamental distinctions between these three technologies is the range of materials they can use and the processes involved.

- 3D Printing: 3D printing often uses a limited selection of materials, such as thermoplastics, photopolymers, or metals, depending on the specific technology. The layer-by-layer deposition is typically achieved through extrusion or curing processes.

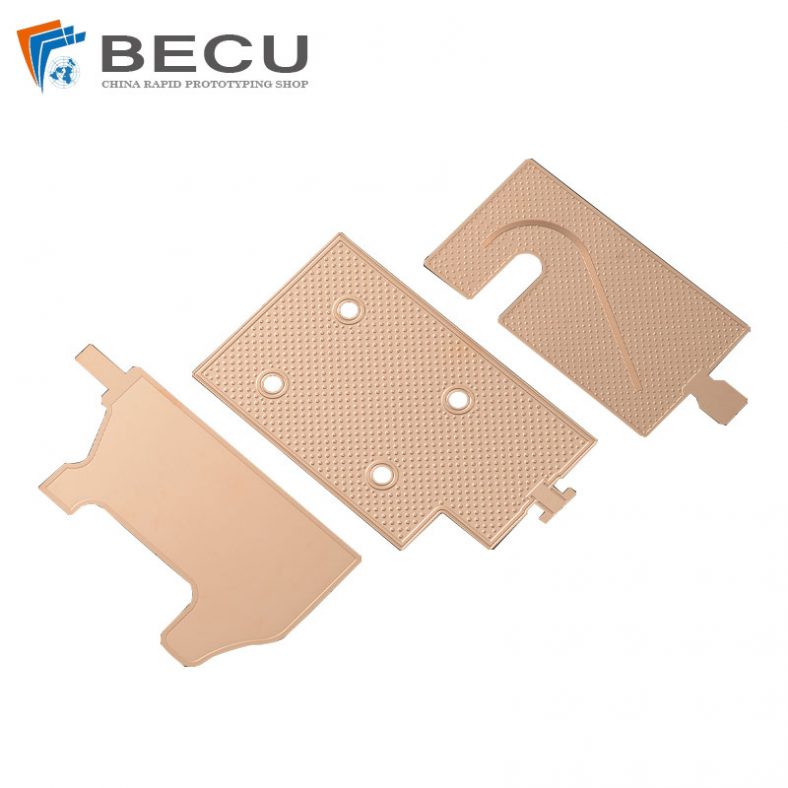

- Additive Manufacturing: Additive manufacturing encompasses a broader spectrum of materials, including plastics, metals, ceramics, and even composites. The choice of material depends on the specific AM technology employed, allowing for greater versatility.

- Rapid Prototyping: Rapid prototyping shares the material range of additive manufacturing but focuses on rapidity and simplicity. It may utilize lower-cost materials, prioritizing speed and cost-effectiveness over material diversity.

2.2. Applications and Industries

Each of these technologies has found its niche within various industries and applications.

- 3D Printing: 3D printing has made significant inroads in industries like aerospace, healthcare (e.g., custom prosthetics), and consumer goods (e.g., customized phone cases). It’s often used for producing intricate and detailed objects.

- Additive Manufacturing: Additive manufacturing shines in aerospace and automotive sectors, where the production of complex and lightweight parts is essential. It’s also gaining traction in healthcare for creating patient-specific medical implants.

- Rapid Prototyping: Rapid prototyping is primarily employed in product design and engineering for quickly validating designs and concepts. It’s especially valuable in industries where design iterations are frequent.

2.3. Speed and Production Volume

Speed and production volume are critical considerations for choosing the right technology.

- 3D Printing: 3D printing, while precise, can be relatively slow compared to other methods. It is best suited for small-scale production or single prototypes.

- Additive Manufacturing: Additive manufacturing can be faster than 3D printing, particularly in industrial settings where multiple machines can work simultaneously. It’s well-suited for producing small to medium batches of parts.

- Rapid Prototyping: As the name suggests, rapid prototyping prioritizes speed over large-scale production. It excels at quickly creating prototypes and small quantities of parts.

Section 3: Technological Evolution

3.1. Advancements in 3D Printing

Over the years, 3D printing technology has seen significant advancements, including:

- Improved Printing Speed: Innovations in extrusion technology and layering techniques have led to faster 3D printing processes.

- Enhanced Material Compatibility: The range of printable materials has expanded, including biocompatible materials for medical applications and high-strength materials for engineering purposes.

- Multi-Material and Multi-Color Printing: Some 3D printers can now simultaneously use multiple materials and colors in a single print, expanding design possibilities.

3.2. The Evolution of Additive Manufacturing

Additive manufacturing has seen a multitude of developments, such as:

- Large-Scale Production: Some AM technologies, like binder jetting and directed energy deposition, are now capable of producing large-scale components for aerospace and automotive industries.

- Metal Additive Manufacturing: The ability to 3D print metal parts has opened up new opportunities in aerospace, healthcare, and the production of high-stress components.

- Hybrid Manufacturing: The integration of AM with conventional manufacturing processes has enabled the creation of complex, high-precision parts.

3.3. Rapid Prototyping’s Transformative Journey

Rapid prototyping has also evolved significantly:

- Faster Prototyping: Rapid prototyping technologies have become faster and more accessible, reducing lead times in product development.

- Realistic Prototypes: Advances in materials and color capabilities allow for more realistic and functional prototypes that closely resemble the final product.

- Integration with CAD Software: Seamless integration with CAD software has streamlined the design-to-prototype process, enhancing efficiency.

Section 4: Advantages and Limitations

4.1. Advantages

3D Printing:

- Precise and intricate designs

- Easy setup and operation

- Suitable for small-scale production and customization

Additive Manufacturing:

- Wide range of materials

- High production efficiency

- Complex geometries and lightweight structures

Rapid Prototyping:

- Rapid design validation

- Cost-effective for small quantities

- Quick turnaround

4.2. Limitations

3D Printing:

- Limited material choices

- Slower production speed

- Less suitable for large-scale production

Additive Manufacturing:

- Initial setup cost

- Post-processing requirements

- Material limitations for certain technologies

Rapid Prototyping:

- Limited to prototyping and small batches

- Less focus on material quality

- Not suitable for mass production

Section 5: Case Studies

To illustrate the practical applications of these technologies, let’s explore some real-world case studies:

5.1. Aerospace Innovation with Additive Manufacturing

- Discuss how aerospace companies like Boeing and Airbus are using AM for lightweight, high-strength components.

- Highlight specific components and cost savings achieved through AM.

5.2. Custom Medical Solutions with 3D Printing

- Explore how 3D printing is revolutionizing the medical field with custom implants, prosthetics, and surgical guides.

- Showcase successful cases of patient-specific treatments.

5.3. Rapid Prototyping in Consumer Electronics

- Examine how consumer electronics companies employ rapid prototyping to iterate designs quickly and bring new products to market faster.

- Highlight examples of consumer gadgets benefiting from rapid prototyping.

Section 6: Future Trends and Challenges

6.1. Future Trends

- Enhanced Materials: Continued development of advanced materials for 3D printing and AM, including smart materials and composites.

- Industry 4.0 Integration: Integration of these technologies into smart factories, improving automation and efficiency.

- Sustainability: Focus on eco-friendly materials and processes to reduce environmental impact.

6.2. Challenges

- Intellectual Property Concerns: The potential for 3D printing to facilitate intellectual property infringement and counterfeiting.

- Regulatory Hurdles: The need for clear regulatory frameworks, especially in healthcare and aerospace, to ensure product safety and quality.

- Material Recycling: Developing efficient methods for recycling and reusing materials in 3D printing and AM processes.

3D printing, additive manufacturing, and rapid prototyping are three distinct yet closely related technologies that have transformed the landscape of manufacturing and product development. Each has its unique advantages, limitations, and applications.

As technology continues to advance, these technologies will play an even more significant role in shaping industries and fostering innovation. It is crucial for businesses and individuals to understand their differences and choose the right technology for their specific needs and objectives.

Whether you are designing custom medical implants, manufacturing aerospace components, or rapidly iterating consumer electronics, the choice between 3D printing, additive manufacturing, and rapid prototyping can make a significant impact on the success of your project. Embracing these technologies wisely can lead to more efficient, cost-effective, and innovative outcomes in the ever-evolving world of manufacturing and product development.